Novemba . 08, 2024 14:42 Back to list

oil seal for rotating shaft

Understanding Oil Seals for Rotating Shafts

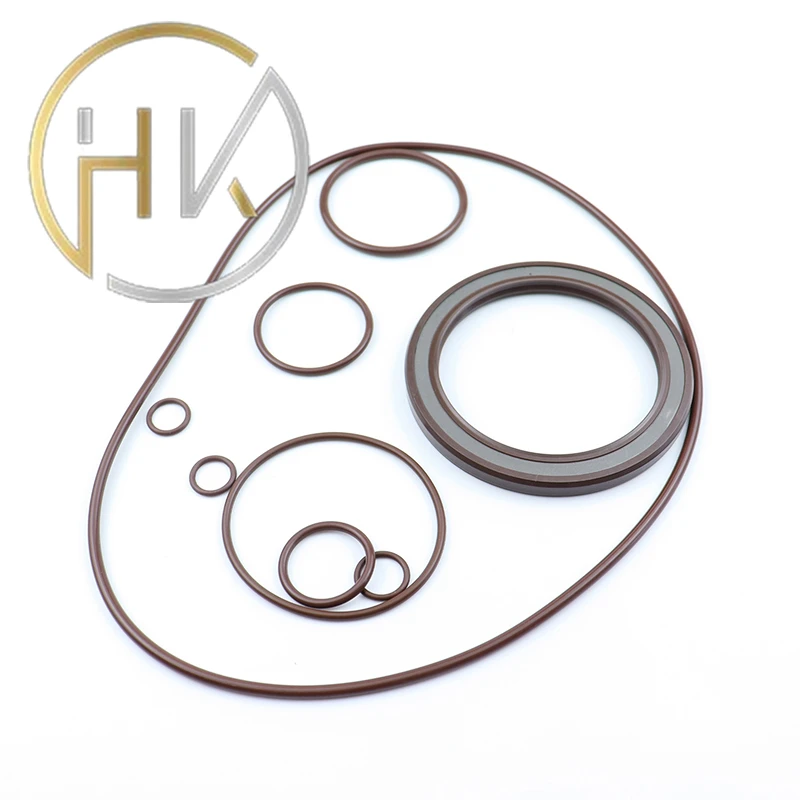

Oil seals, also known as shaft seals or rotary shaft seals, play a crucial role in various mechanical systems by preventing the leakage of oils and lubricants. These seals are designed to accommodate rotating shafts that are integral to numerous applications across industries, including automotive, aerospace, manufacturing, and heavy machinery. Understanding the function, design, and application of oil seals for rotating shafts is vital for effective maintenance and operation of machinery.

What is an Oil Seal?

An oil seal consists of a rubber or elastomeric body that fits around the shaft, creating a sealing barrier between the rotating shaft and the housing. The primary function of an oil seal is to contain lubricants within a specified area while preventing contaminants like dust, dirt, and moisture from entering. This is essential for ensuring the longevity and proper functionality of the machinery, as lubricant leakage can lead to increased wear and tear, overheating, and potential failure of the mechanical components.

Key Components of an Oil Seal

1. Seal Body The body of the oil seal is typically made from durable elastomers, such as nitrile rubber, which can withstand high temperatures and resist degradation from oils.

2. Lip The sealing lip is the critical element that makes contact with the shaft. Its design determines how effectively the seal can retain oil and exclude contaminants. The lip is often coated with a thin film of oil to enhance performance and minimize wear.

3. Spring Many oil seals are equipped with a garter spring that applies consistent pressure to the sealing lip, ensuring a tight seal against the rotating shaft.

4. Backup Ring In some applications, a backup ring is used to provide additional support and maintain the integrity of the seal under varying pressure conditions.

Working Principle

oil seal for rotating shaft

The oil seal works on the principle of creating a barrier that prevents fluid migration. When the shaft rotates, the sealing lip compresses against the surface of the shaft, forming a tight seal. The contact created by the elasticity of the material forms a barrier that prevents oil from leaking out while simultaneously keeping contaminants from entering. Additionally, the garter spring maintains pressure on the lip, ensuring consistent performance throughout the lifespan of the seal.

Applications of Oil Seals

1. Automotive Industry Oil seals are extensively used in engines, transmissions, and differentials to prevent the leakage of lubricants. They also play a vital role in wheel bearings and other rotational components.

2. Aerospace In aerospace applications, oil seals are critical for ensuring the reliability of engines and hydraulic systems. The seals must withstand extreme temperatures and pressures while maintaining stringent safety standards.

3. Manufacturing and Machinery Oil seals are found in various types of machinery, including pumps, compressors, and conveyor systems. They help maintain lubrication, thus minimizing operational downtime and maintenance costs.

4. Heavy Equipment Equipment used in construction and mining heavily relies on oil seals to protect vital components from dust and abrasive materials often encountered in harsh environments.

Selecting the Right Oil Seal

Choosing the right oil seal for an application involves considering various factors, including the type of lubricant, operating temperature range, shaft speed, and potential exposure to contaminants. It's essential to consult suppliers or manufacturers to select seals that conform to the necessary specifications for pressure, size, and material compatibility.

Conclusion

Oil seals for rotating shafts are integral to the functionality and maintenance of various mechanical systems. By effectively containing lubricants and preventing contaminants from entering, these seals prolong the life of machinery and ensure operational efficiency. Understanding their design, application, and selection is crucial for engineers, technicians, and maintenance professionals alike. By investing in quality oil seals and recognizing their importance in system design, operators can significantly reduce the risk of failures and enhance the performance of their equipment.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories