Desemba . 02, 2024 07:25 Back to list

hydraulic press seal kit

Understanding Hydraulic Press Seal Kits A Comprehensive Guide

When it comes to hydraulic systems, maintaining the integrity and efficiency of the components is crucial for optimal performance. One of the pivotal components in this system is the hydraulic press seal kit. In this article, we will delve into what hydraulic press seal kits are, their importance, common types, and maintenance tips to ensure longevity and reliability.

What is a Hydraulic Press Seal Kit?

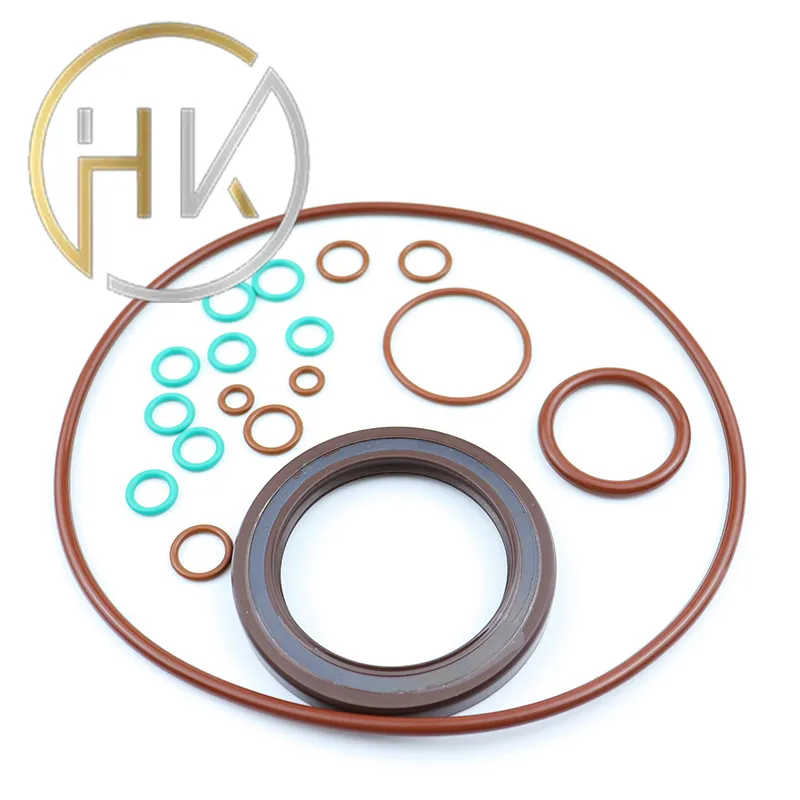

A hydraulic press seal kit is a collection of seals and gaskets specifically designed for hydraulic presses. These seals play a vital role in preventing fluid leakage between different components, ensuring that the hydraulic fluid remains contained within the system. They also help maintain the pressure necessary for the hydraulic press to function correctly.

Hydraulic press seal kits typically include components such as O-rings, rod seals, piston seals, and backup rings, each tailored to fit specific applications and provide resistance against wear and tear, high pressures, and extreme temperatures.

Importance of Hydraulic Press Seal Kits

The importance of hydraulic press seal kits cannot be overstated. Here are a few key reasons why they are essential in hydraulic systems

1. Leak Prevention One of the primary functions of seals is to prevent hydraulic fluid from leaking out, which can lead to decreased efficiency and environmental hazards. A well-sealed hydraulic system functions optimally, maintaining productivity without wasting resources.

2. Pressure Maintenance The seals within a hydraulic system play a crucial role in maintaining the necessary pressure required for operation. If the seals fail, the system may not be able to generate the power needed for the hydraulic press to function effectively.

3. Cushioning Mechanism Many hydraulic systems rely on the cushioning effect created by properly functioning seals. This is particularly important in applications that involve heavy loads or impact forces that can cause wear over time.

4. Contamination Protection Seals act as barriers that prevent dirt, dust, and other contaminants from entering the hydraulic system. Contaminated hydraulic fluid can accelerate wear on internal components, leading to breakdowns and costly repairs.

Common Types of Hydraulic Press Seal Kits

Hydraulic press seal kits come in various types, each designed for specific applications

. Some of the most common types includehydraulic press seal kit

- O-Ring Kits These are circular seals that are versatile and can be used in various hydraulic applications. They are known for their simplicity and effectiveness in preventing leaks.

- Piston Seal Kits These seals are specifically designed to fit around hydraulic pistons, providing a tight seal to prevent fluid from escaping as the piston moves.

- Rod Seal Kits Similar to piston seals, rod seals are designed for hydraulic rods, ensuring smooth operation while preventing fluid leaks.

- Gasket Kits Gaskets are used for larger joints and surfaces that require sealing. They provide a larger sealing area and are ideal for high-pressure applications.

Maintenance Tips for Hydraulic Press Seal Kits

To ensure the longevity and effective performance of hydraulic press seal kits, regular maintenance is essential. Here are some tips to consider

1. Regular Inspection Frequently check the seals for signs of wear, such as cracks or deformation. Early detection of wear can prevent catastrophic system failures.

2. Proper Lubrication Applying the right lubricant can reduce friction and wear on the seals. Ensure that you use manufacturer-recommended lubricants to maintain compatibility.

3. Temperature and Pressure Monitoring Keep an eye on the operating temperature and pressure of the hydraulic system to prevent overheating, which can lead to seal failure.

4. Replacement of Worn Seals It is crucial to replace seals that show signs of excessive wear. Waiting too long can lead to more severe damage to the hydraulic system and increased downtime.

5. Cleanliness Ensure the hydraulic fluid and surrounding areas are clean to prevent contamination that could compromise seal integrity.

Conclusion

Hydraulic press seal kits are integral to the effective operation of hydraulic systems. Understanding their components, importance, and maintenance can help ensure the system operates efficiently and reliably. Regular checks and timely replacements of seals can significantly extend the lifespan of hydraulic equipment, ultimately saving time and costs in the long run.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories