Novemba . 28, 2024 23:32 Back to list

Hydraulic Cylinder Kit Solutions for Enhanced Performance and Durability

Understanding Hydraulic Cylinder Kits A Comprehensive Guide

Hydraulic cylinder kits play a crucial role in various industries, ranging from automotive to manufacturing and construction. These kits are essential components in hydraulic systems, which utilize liquid under pressure to produce mechanical motion. This article delves into the significance of hydraulic cylinder kits, their components, how to choose the right kit, and their applications.

What is a Hydraulic Cylinder?

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy into linear force and motion. It consists of a cylinder barrel, a piston, and an end cap. When hydraulic fluid is pumped into the cylinder, it creates pressure that pushes the piston, causing it to move and perform work. The versatility and efficiency of hydraulic cylinders have made them indispensable in a variety of applications, including lifting, pushing, and pulling tasks.

Components of Hydraulic Cylinder Kits

A complete hydraulic cylinder kit typically includes several essential components

1. Cylinder Barrel This serves as the main body of the cylinder, holding the hydraulic fluid. It is usually made from steel or aluminum to withstand high pressures.

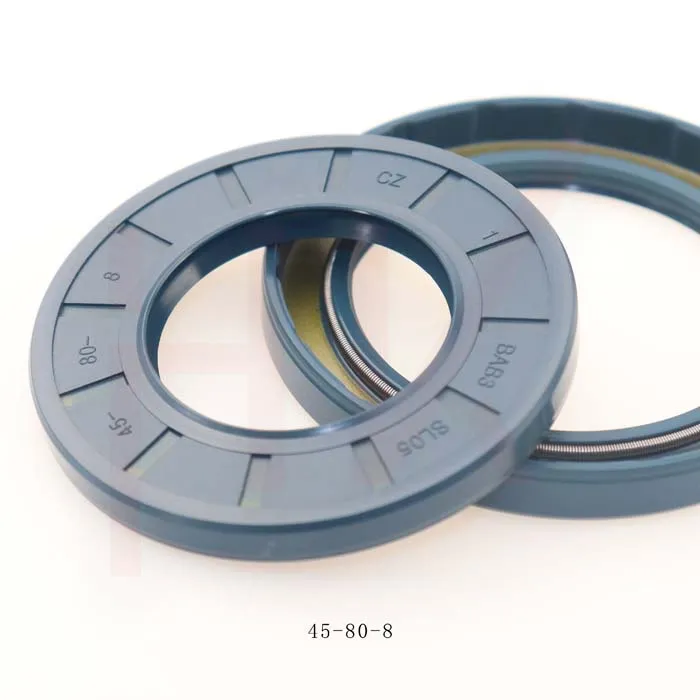

2. Piston The piston slides inside the cylinder and is responsible for converting hydraulic energy into mechanical work. It typically has seals that prevent leakage of hydraulic fluid.

3. Rod Connected to the piston, the rod extends out of the cylinder and transmits force to machine components or tools.

4. End Caps These are screw-on or welded components that secure the piston inside the cylinder. They also support seals that maintain fluid pressure.

6. Ports These are openings through which hydraulic fluid enters and exits the cylinder, allowing for the control of the cylinder’s movement and pressure.

Choosing the Right Hydraulic Cylinder Kit

hydraulic cylinder kits

When selecting a hydraulic cylinder kit, several factors should be considered to ensure optimal performance and longevity

1. Capacity Requirements Determine the load that the cylinder needs to lift or push. Hydraulic cylinders are rated for specific pressures and loads, so choose a kit that matches or exceeds your requirements.

2. Stroke Length This refers to the distance the piston travels within the cylinder. Determine the necessary stroke length for your application to ensure proper function.

3. Mounting Options Consider how the cylinder will be mounted in your machinery. Different mounting styles (e.g., front flange, trunnion, or clevis mounting) may be required based on space and application needs.

4. Operating Environment Assess the conditions in which the cylinder will operate. Exposure to harsh environments, chemicals, or extreme temperatures may require specialized materials or coatings.

5. Hydraulic Fluid Type Different hydraulic fluids can affect the performance and compatibility of the cylinder. Ensure that the selected kit is compatible with the fluid you intend to use.

6. Maintenance Needs Choose a kit that allows for easy maintenance and replacement of seals or components to prolong the service life of your hydraulic system.

Applications of Hydraulic Cylinder Kits

Hydraulic cylinder kits are widely utilized across various industries

- Construction Used in heavy machinery such as excavators and bulldozers for lifting and moving materials. - Automotive Applied in lift gates, hydraulic brakes, and assembly line machinery. - Manufacturing Employed in machines for metal forming, industrial presses, and robotics. - Agriculture Utilized in equipment like tractors and harvesters for lifting and adjusting implements.

Conclusion

Hydraulic cylinder kits are essential for a myriad of applications that require reliable and efficient power. By understanding their components, how to choose the right kit, and their various applications, businesses can maximize productivity and ensure the longevity of their hydraulic systems. Investing in quality hydraulic cylinder kits can lead to improved performance, reduced downtime, and ultimately enhance overall operational efficiency.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories