Desemba . 18, 2024 03:39 Back to list

gearbox seals

Understanding Gearbox Seals Importance, Types, and Maintenance

Gearbox seals are essential components in various mechanical systems, particularly in the automotive and industrial sectors. They serve a critical function in ensuring the efficient operation and longevity of gearboxes by preventing the leakage of lubricants and contamination from external elements. This article explores the significance of gearbox seals, their types, and best practices for maintenance.

The Importance of Gearbox Seals

Gearboxes play a pivotal role in delivering power from an engine to the wheels or machinery. They operate under high-pressure conditions and are exposed to various environmental factors. Effective seals are crucial to keep the lubricant within the gearbox, which reduces friction and wear on the gears. A well-sealed gearbox ensures optimal performance, reduces the risk of overheating, and ultimately extends the lifespan of the components.

One of the major issues faced by gearboxes is oil leakage. When lubricant escapes, it not only diminishes the effectiveness of the lubrication system but can also lead to catastrophic failures, increased operating temperatures, and costly repairs. Additionally, contaminants such as dirt and moisture can enter through inadequately sealed components, leading to corrosion and further damage. Therefore, maintaining the integrity of gearbox seals is paramount for operational efficiency and machinery reliability.

Types of Gearbox Seals

There are several types of seals used in gearboxes, and each serves a specific purpose. Here are some of the most common types

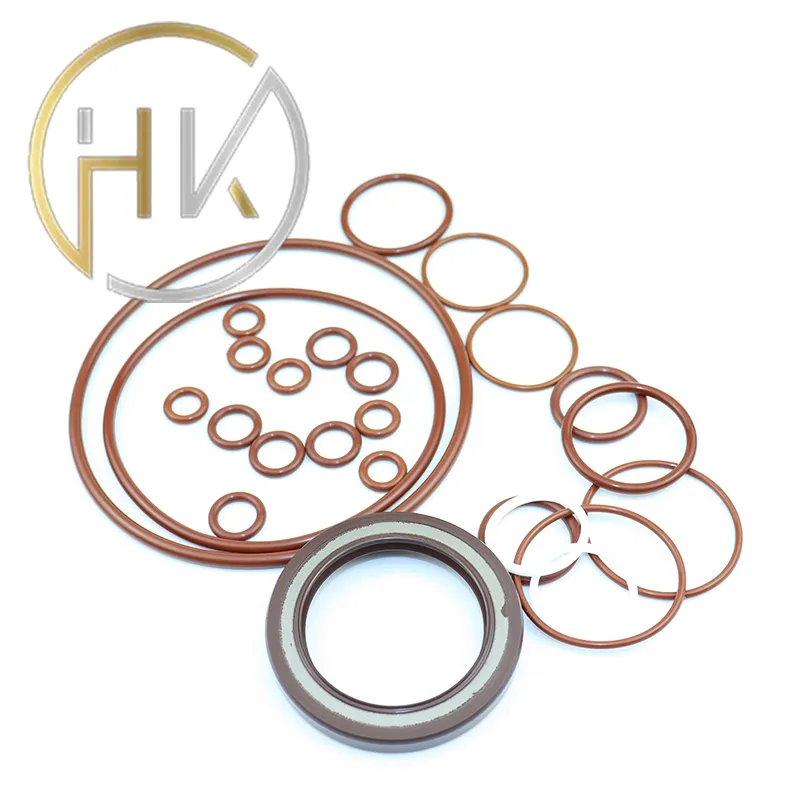

1. Rotary Seals (Lip Seals) These are designed to seal the rotating shafts within the gearbox. They incorporate a flexible lip that makes contact with the shaft, effectively blocking the escape of lubricant while also preventing dirt and moisture ingress.

2. O-Rings These are circular seals that fit into grooves and provide a compressive seal against flat or cylindrical surfaces. O-rings are versatile and often used in low to moderate-pressure applications.

3. Gaskets Gaskets are used to seal static joints between two surfaces. They can be made from various materials, including rubber, cork, or metal, depending on the pressure and temperature conditions.

4. Mechanical Seals Commonly found in high-pressure applications, these seals consist of two surfaces that slide against each other. They create a tight seal that can handle higher pressures and prevent leakage effectively.

gearbox seals

5. Floating Seals These seals have a design that allows them to adjust and adapt to shaft misalignment. They are particularly useful in environments where the shaft may flex or move.

Maintenance of Gearbox Seals

Proper maintenance of gearbox seals is essential for preventing failures and ensuring the optimal functioning of the gearbox. Here are some recommended practices

1. Regular Inspections Periodically inspect seals for signs of wear, cracking, or deformation. Detecting issues early can prevent leaks and subsequent damage to the gearbox.

2. Lubricant Quality Use high-quality lubricants that are recommended for the specific gearbox design. Incompatible lubricants can degrade seals, leading to leaks and failures.

3. Replace Damaged Seals If a seal shows signs of damage or wear, it should be replaced immediately to prevent further issues. Always replace seals in sets when applicable to maintain uniformity.

4. Monitor Operating Conditions Keep an eye on operating temperatures and pressures. Excessive heat or pressure can accelerate seal wear, so operating within recommended ranges is crucial.

5. Proper Installation Ensure seals are installed correctly to avoid misalignment or damage during the assembly process. Following manufacturer guidelines during installation is critical for achieving proper functionality.

Conclusion

In conclusion, gearbox seals play a vital role in the performance and reliability of mechanical systems. Understanding the types of seals available and implementing effective maintenance practices can help prevent costly failures and enhance the longevity of gearboxes. Regular inspections, utilizing quality lubricants, and adhering to best practices during installation are essential steps in ensuring that gearbox seals function optimally. By prioritizing the health of these seals, businesses and individuals can ensure their machinery operates smoothly and efficiently, ultimately leading to increased productivity and reduced operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories