Desemba . 03, 2024 19:04 Back to list

Bottle Jack Repair Kits for Efficient Maintenance and Longevity of Your Equipment

The Importance of Bottle Jack Repair Kits

Bottle jacks, known for their compact design and robust lifting capabilities, are indispensable tools in both professional and homemade workshop settings. They are crucial for lifting vehicles and heavy objects, making tire changes and maintenance tasks significantly easier and safer. However, like any mechanical device, bottle jacks can experience wear and tear over time, leading to a decrease in performance or complete operational failure. This is where bottle jack repair kits come into play, ensuring that these vital tools remain functional and reliable.

Understanding Bottle Jacks

Before diving into the intricacies of repair kits, it is essential to understand how bottle jacks operate. Typically, a bottle jack consists of a hydraulic cylinder, a pump lever, and a base. When the lever is operated, hydraulic fluid is drawn into the cylinder, creating pressure that lifts the jack and any attached load. Despite their sturdy construction, bottle jacks can suffer from several common issues, such as fluid leaks, internal seal degradation, or even complete hydraulic failure.

Symptoms of a Failing Bottle Jack

Recognizing the signs of a failing bottle jack is the first step toward repair. Some common symptoms include

- Fluid Leakage If you notice oil pooling on the ground beneath your jack, this indicates a problem with the seals. - Slow or Weak Lifting If the jack takes longer than usual to lift objects or struggles with light loads, the hydraulic system may be compromised. - Uneven Lifting If the jack lifts objects unevenly, it could signal internal damage or obstruction. - Hissing Sounds A hissing noise during operation might suggest air in the hydraulic system or a failing seal.

Addressing these issues as soon as they arise can extend the life of your bottle jack and prevent more costly repairs or replacements.

The Role of Repair Kits

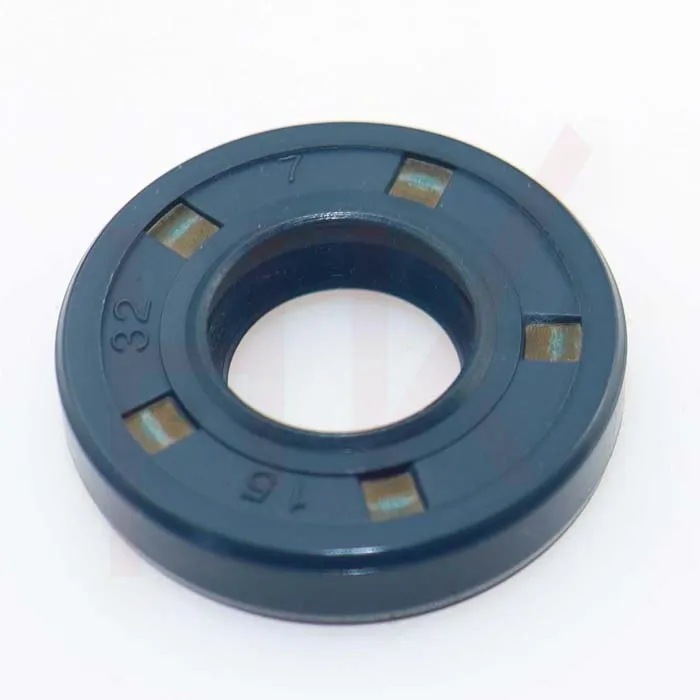

Bottle jack repair kits are designed to address many of the issues that can arise with these tools. A typical repair kit includes various components such as

- Seals and O-rings These are crucial for maintaining hydraulic fluid retention. - Retaining Rings Used to keep mechanical components in place within the jack. - Hydraulic Fluid Essential for the operation of the jack; some kits may include replacement fluid. - Instruction Manuals Many kits come with detailed instructions on how to replace parts and service the jack.

bottle jack repair kits

By utilizing a repair kit, users can save money that would otherwise be spent on replacement jacks or professional repairs. Learning to repair your bottle jack not only fosters self-sufficiency but also develops a greater understanding of the tools that aid in maintenance tasks.

How to Repair Your Bottle Jack

Repairing a bottle jack can seem daunting at first, but with the right tools and a bit of patience, anyone can learn the process. Here’s a simplified guide on how to perform basic repairs

1. Disassembly Start by releasing all hydraulic pressure. Remove the jack from any load, then take it apart according to the instructions provided in the repair kit. 2. Inspection Inspect all internal components, looking for signs of wear or damage. Pay special attention to seals and O-rings, as these are often the first to degrade.

3. Replacing Parts Remove the old seals and O-rings, and replace them with new ones from the kit. Ensure that everything fits snugly to avoid future leaks.

4. Refilling Hydraulic Fluid If your kit comes with hydraulic fluid, refill the jack according to the manufacturer's specifications.

5. Reassembly Carefully reassemble the jack, making sure that all components are secured properly.

6. Testing Once reassembled, test the jack by lifting a load to ensure it operates smoothly.

Conclusion

Bottle jack repair kits are essential for maintaining the longevity and performance of this valuable equipment. By quickly addressing symptoms of wear and using repair kits, users can save time and resources while ensuring their hydraulic jacks operate at peak performance. Not only does this promote safety during lifting tasks, but it also cultivates a spirit of self-reliance and an understanding of hydraulic systems. Whether in a professional garage or a home workshop, having a bottle jack repair kit on hand is a smart decision for any DIY enthusiast or professional mechanic.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories