Januari . 29, 2025 00:44 Back to list

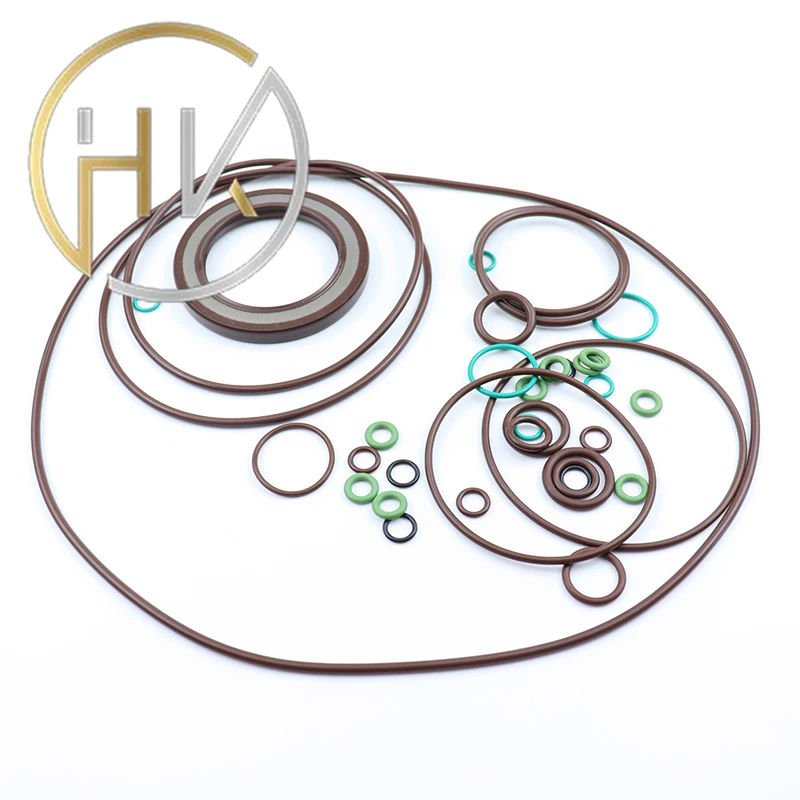

8mm shaft seal

Investing in high-quality 8mm shaft seals and securing professional services for their installation and maintenance translates directly to enhanced system reliability and performance. In industries where machinery downtime can result in significant financial loss, the assurance of a well-fitted seal backed by authoritative expertise is a strategic advantage. Trust in your system’s components extrapolates to trust in the manufacturers and service providers behind these components. Leading companies known for producing reliable 8mm shaft seals often have a track record characterized by advanced testing protocols, quality assurance certifications, and a history of innovation in seal technology. End-users benefit from the peace of mind that comes with using products from manufacturers with a legacy of quality adherence and customer satisfaction. Therefore, whether you are an engineer specifying components for a new design, a maintenance technician tasked with machinery upkeep, or a procurement officer responsible for the sourcing of critical parts, understanding the nuances of 8mm shaft seals is paramount. Their expert selection and maintenance reflect a commitment to ensuring operational excellence and a dedication to leveraging the refined knowledge and skills of professionals in the field. In summary, the 8mm shaft seal is a quintessential part of industrial machinery, entwined with multiple aspects of engineering expertise and seasoned experience. Its proper utilization exemplifies a blend of technical knowledge and practical application, ultimately fortifying the machinery’s operational integrity while bolstering the reputation of those who wield such expertise.

-

DKBI Hydraulic Wiper Seal 20x32x6/9 | Dustproof & Standard Oil Seal

NewsAug.30,2025

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

NewsAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

Products categories