Februari . 08, 2025 06:24 Back to list

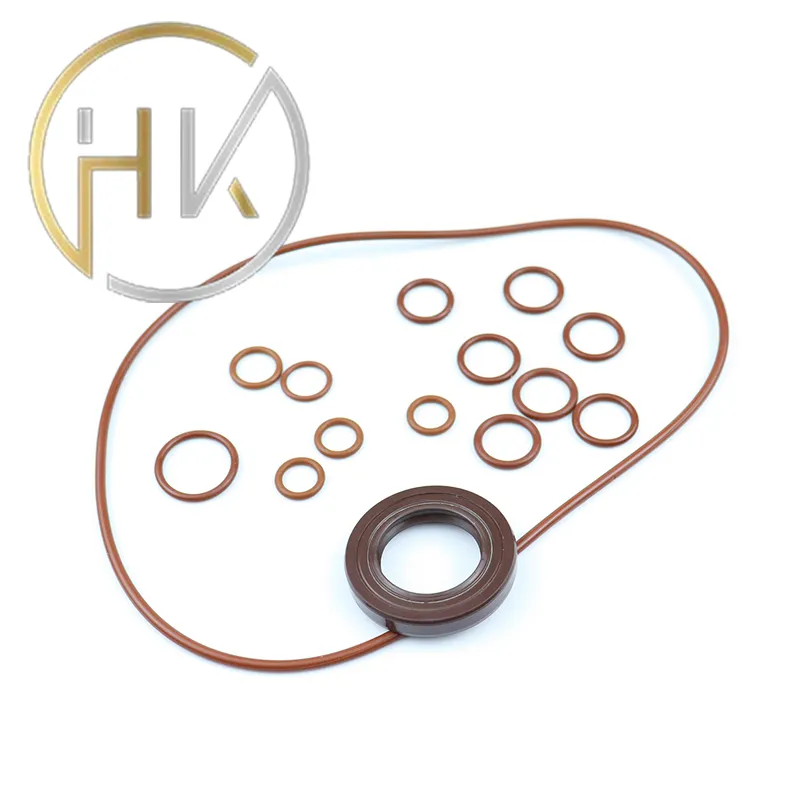

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Exploring the Interplay of Design and Functionality A Deep Dive into the 2-Inch Hydraulic Cylinder Seal

The precision manufacturing of a 2-inch hydraulic cylinder seal demands an intersection of cutting-edge technology and craftsmanship. Computer-aided design (CAD) tools and finite element analysis (FEA) are frequently employed to simulate performance and stress scenarios, leading to more reliable and efficient seal designs. This combination of innovation and expertise results in products that not only meet but often exceed industry standards. Moreover, routine inspection and maintenance are instrumental in extending the operational life of hydraulic seals. Regular monitoring for signs of wear, such as surface abrasions or material degradation, enables prompt interventions, preventing potential systemic failures. Employing a preventative maintenance approach not only reduces downtime but also enhances overall system reliability. From a sectoral perspective, a wide range of industries, including construction, agriculture, and manufacturing, rely on these seals for their operational demands. In each context, the adaptability and robustness of the 2-inch hydraulic cylinder seal allow for seamless integration, underscoring its versatility and vital role in modern engineering. With a focus on design efficiency and material advancement, the 2-inch hydraulic cylinder seal exemplifies the intricate balance between industry expertise and practical application. Its impact on hydraulic system performance remains irreplaceable, making it an area worthy of continued attention and development. As research progresses and technology evolves, these seals will undoubtedly continue to adapt, addressing new challenges and setting benchmarks in mechanized fluid power systems. Adopting innovative approaches and diligent maintenance practices will remain imperative for maximizing these seals' potential, thereby ensuring they remain at the forefront of hydraulic system efficiency and reliability.

The precision manufacturing of a 2-inch hydraulic cylinder seal demands an intersection of cutting-edge technology and craftsmanship. Computer-aided design (CAD) tools and finite element analysis (FEA) are frequently employed to simulate performance and stress scenarios, leading to more reliable and efficient seal designs. This combination of innovation and expertise results in products that not only meet but often exceed industry standards. Moreover, routine inspection and maintenance are instrumental in extending the operational life of hydraulic seals. Regular monitoring for signs of wear, such as surface abrasions or material degradation, enables prompt interventions, preventing potential systemic failures. Employing a preventative maintenance approach not only reduces downtime but also enhances overall system reliability. From a sectoral perspective, a wide range of industries, including construction, agriculture, and manufacturing, rely on these seals for their operational demands. In each context, the adaptability and robustness of the 2-inch hydraulic cylinder seal allow for seamless integration, underscoring its versatility and vital role in modern engineering. With a focus on design efficiency and material advancement, the 2-inch hydraulic cylinder seal exemplifies the intricate balance between industry expertise and practical application. Its impact on hydraulic system performance remains irreplaceable, making it an area worthy of continued attention and development. As research progresses and technology evolves, these seals will undoubtedly continue to adapt, addressing new challenges and setting benchmarks in mechanized fluid power systems. Adopting innovative approaches and diligent maintenance practices will remain imperative for maximizing these seals' potential, thereby ensuring they remain at the forefront of hydraulic system efficiency and reliability.

Next:

Latest news

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories