Oktoba . 31, 2024 18:24 Back to list

20x30x7mm Oil Seal Specifications and Applications Overview for Various Industries

Understanding the Importance of the 20x30x7 Oil Seal

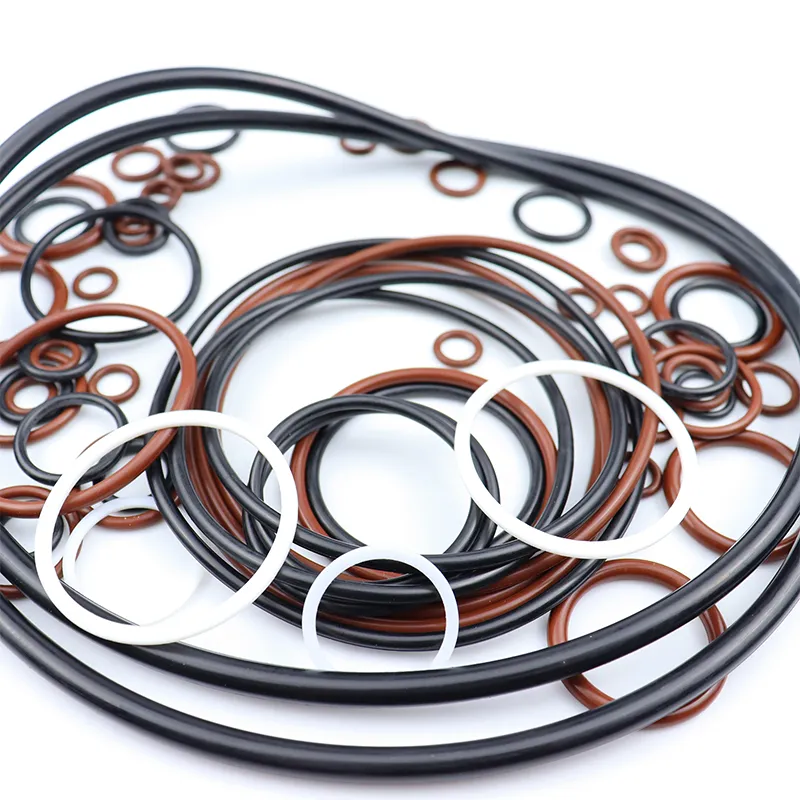

In various mechanical and industrial applications, oil seals play a crucial role in ensuring the efficiency and longevity of machinery. One specific type that merits attention is the 20x30x7 oil seal, which is characterized by its dimensions a 20mm inner diameter, a 30mm outer diameter, and a 7mm cross-section. These seals are designed to prevent the leakage of lubricants while protecting the internal components from dirt, dust, and moisture.

Key Features

The 20x30x7 oil seal is manufactured from durable materials, typically elastomers like nitrile rubber, silicone, or polyurethane, which provide exceptional resistance to wear and tear. One of the key features of this oil seal is its ability to maintain a tight seal even in high-pressure and high-temperature environments. This is essential for applications in automotive engines, hydraulic systems, and various types of industrial machinery.

The specific dimensions of 20x30x7 make it a versatile choice for numerous applications. The inner diameter of 20mm allows it to fit snugly onto shafts or fittings of the same size, while the outer diameter of 30mm ensures a secure fit within the housing. The 7mm cross-section provides robust sealing capabilities, making it effective in containing the lubricants that are vital for proper machine operation.

Applications

The 20x30x7 oil seal is widely utilized in different sectors. In automotive applications, it is commonly found in engine components, gearboxes, and differential assemblies. The seal helps to prevent oil from leaking out of these components, which can lead to lower lubrication levels, resulting in higher friction, wear, and ultimately, mechanical failure.

20x30x7 oil seal

In industrial equipment, the 20x30x7 oil seal is often used in hydraulic cylinders and pumps, where maintaining fluid integrity is essential. The seal not only prevents the escape of hydraulic fluid but also protects against contamination from external debris. This is critical for maintaining performance, safety, and operational reliability in heavy machinery and systems.

Installation and Maintenance

Proper installation of the 20x30x7 oil seal is vital for its performance. The sealing surface must be clean and free of any debris to ensure a tight fit. Using the correct installation tools and techniques can prevent damage to the seal during the process. Regular inspection and maintenance of the oil seal are also important. Signs of wear, such as cracks or deformation, should be addressed immediately to avoid unexpected failures.

When replacing oil seals, it is always advisable to choose high-quality products that meet industry standards. Inferior seals can lead to frequent leaks, increased downtime, and higher operational costs.

Conclusion

In summary, the 20x30x7 oil seal is an essential component in various mechanical systems, offering reliability and protection against leaks and contamination. Its unique dimensions and durable materials make it suitable for a wide range of applications across different industries. Proper installation and maintenance of this oil seal are key to ensuring that machinery runs smoothly and efficiently. Investing in high-quality seals not only enhances performance but also extends the life of the machinery, ultimately contributing to lower maintenance costs and improved operational efficiency.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories