nov . 08, 2024 21:48 Back to list

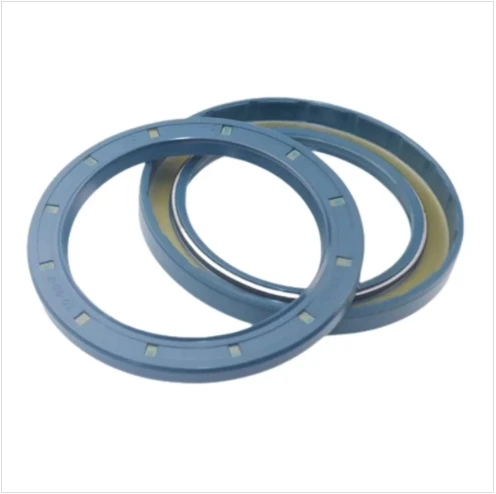

dust proof sealing

Understanding Dust Proof Sealing Importance and Applications

In our increasingly technology-driven world, protecting sensitive equipment from environmental elements is paramount. Among these elements, dust stands out as a pervasive and potentially damaging force. This is where dust proof sealing becomes essential. Dust proof sealing refers to the techniques and materials employed to create a barrier that prevents dust and other particulates from entering an enclosure. This article explores the importance of dust proof sealing, its applications, and the various materials commonly used in this process.

The Importance of Dust Proof Sealing

Dust can wreak havoc on electronic devices, mechanical equipment, and any machinery that relies on precision and cleanliness for optimal performance. Dust particles can accumulate over time, causing overheating, increased wear and tear, and ultimately device malfunction. Therefore, effective dust proof sealing is crucial in extending the lifespan of equipment and ensuring operational efficiency.

In industries such as manufacturing, food processing, pharmaceuticals, and electronics, maintaining a dust-free environment is not just a matter of efficiency; it is often mandated by strict health and safety regulations. For instance, in the pharmaceutical industry, the presence of dust can lead to contamination of products, which can have serious health implications. Hence, reliable dust sealing solutions are imperative for compliance and safety.

Applications of Dust Proof Sealing

Dust proof sealing finds applications across a diverse range of sectors

1. Electronics In the electronics industry, devices such as computers, smartphones, and televisions require effective sealing to prevent dust accumulation on sensitive components. This is especially crucial for high-performance devices where dust can hinder heat dissipation and lead to malfunctions.

2. Automotive Modern vehicles are packed with electronic systems, including control units and infotainment systems, which need protection from dust and debris. Dust proof sealing in automotive contexts not only enhances performance but also contributes to the longevity of the vehicle’s components.

3. Industrial Equipment Machines used in harsh environments, such as construction sites or metalworking facilities, benefit significantly from dust proof seals. These seals help in maintaining the internal integrity of equipment, contributing to uninterrupted operations.

dust proof sealing

4. Home Appliances Everyday appliances like vacuum cleaners, air conditioners, and refrigerators also incorporate dust proof sealing to ensure efficient operation and longevity. In these cases, seals prevent the ingress of dust, improving performance and reducing the need for maintenance.

5. Telecommunications Equipment used in telecommunications, including pole-mounted switches and relay boxes, must withstand exposure to the environment. Dust proof sealing plays a vital role in protecting sensitive components from dust, moisture, and other potential contaminants.

Common Materials Used for Dust Proof Sealing

Several materials can be utilized for effective dust proof sealing, and the choice often depends on the specific application and environmental conditions

- Gaskets Made from rubber or silicone, gaskets are commonly used as a sealing component between surfaces. They provide an effective barrier against dust while also accommodating thermal expansion.

- O-rings These circular seals are utilized in a range of applications to provide a dust tight seal. O-rings are typically made from materials like nitrile or fluorocarbon, selected based on the environmental conditions and the substances they may encounter.

- Foam Seals Soft foam materials can be engineered to fit snugly into a housing, providing excellent dust sealing capabilities. They compress easily, making them suitable for applications requiring flexibility.

- Specialty Coatings Some applications utilize coatings designed to repel dust and contaminants. These coatings can be applied to surfaces to create a dust-resistant barrier.

Conclusion

As technology continues to advance and industries evolve, the need for effective dust proof sealing becomes increasingly vital. By understanding the importance and applications of dust proof sealing, companies can ensure enhanced operational efficiency and compliance with safety regulations. The selection of appropriate sealing materials will further play a crucial role in protecting sensitive equipment and extending its operational life. Ultimately, investing in quality dust proof sealing solutions is an investment in reliability, efficiency, and long-term success.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories