dec . 11, 2024 02:09 Back to list

Essential Hydraulic Cylinder Seal Kit for Chief Equipment Maintenance and Repair

Understanding Chief Hydraulic Cylinder Seal Kits A Comprehensive Guide

Hydraulic systems play a crucial role in various industrial applications, from manufacturing equipment to heavy machinery. At the heart of these hydraulic systems lies the hydraulic cylinder, a component responsible for converting hydraulic energy into mechanical force. Ensuring the optimal performance and longevity of hydraulic cylinders depends significantly on the quality and condition of their seals. This is where Chief hydraulic cylinder seal kits come into play.

What is a Hydraulic Cylinder Seal Kit?

A hydraulic cylinder seal kit is a collection of seals and related components designed to fit a specific type of hydraulic cylinder. These kits are vital for preventing leaks, maintaining pressure, and ensuring the efficient operation of hydraulic systems. Chief seal kits are particularly well-regarded in the industry for their reliability and quality, making them a preferred choice among engineers and technicians.

Importance of Quality Seals

Seals in hydraulic cylinders serve several critical functions. They

1. Prevent Fluid Leakage Seals maintain the integrity of hydraulic fluid within the cylinder, preventing it from leaking out. Fluid leakage can lead to reduced efficiency and performance, as well as environmental concerns.

2. Maintain Pressure A good seal helps to maintain the required pressure within the hydraulic system, ensuring that it operates effectively. Loss of pressure can result in decreased power output and responsiveness.

3. Reduce Wear and Tear Quality seals reduce friction between moving parts, leading to less wear and tear on the cylinder and extending its lifespan.

4. Improve Performance With effective seals, hydraulic cylinders can perform at their peak, providing smoother and more reliable operation.

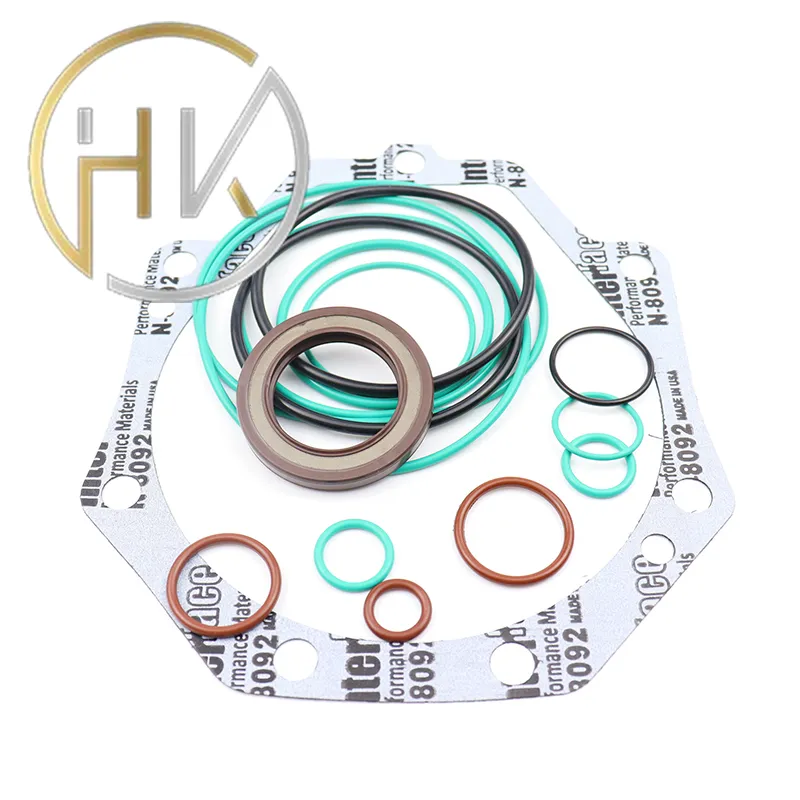

Components of Chief Hydraulic Cylinder Seal Kits

Chief hydraulic cylinder seal kits typically include a variety of seals, such as O-rings, lip seals, and backup rings. Each component has a specific role

- O-Rings These are rubber or elastomeric rings that create a seal between two mating surfaces. They are one of the most common seal types used in hydraulic applications due to their simplicity and effectiveness.

- Rod Seals These seals are located around the piston rod of the hydraulic cylinder, preventing fluid from leaking out while allowing the rod to move freely

.- Piston Seals These seals are situated inside the cylinder and are essential for maintaining pressure. They facilitate the movement of the piston while preventing hydraulic fluid from bypassing.

chief hydraulic cylinder seal kit

- Wipers These seals help to keep contaminants such as dirt and debris out of the cylinder, protecting the internal components and ensuring clean operation.

Choosing the Right Seal Kit

Selecting the correct Chief hydraulic cylinder seal kit involves considering several factors

1. Compatibility Ensure the seal kit is compatible with your specific hydraulic cylinder model. Mismatched seals can lead to leaks and system failure.

2. Material Different applications require different seal materials. For example, high-temperature or high-pressure applications may necessitate seals made from specialized materials that can withstand extreme conditions.

3. Environmental Considerations If the hydraulic system operates in harsh environments, selecting seals that can resist abrasives and corrosive substances is essential.

4. Quality Assurance Always choose seal kits from reputable manufacturers like Chief, which are known for their quality and reliability.

Maintenance Tips for Hydraulic Seals

To maximize the life of hydraulic seals and prevent premature failure, consider the following maintenance practices

- Regular Inspections Periodically check seals for signs of wear, cracks, or damage. Early detection can save time and money on more extensive repairs.

- Fluid Quality Use the correct hydraulic fluid to prevent seal degradation. Contaminated or inappropriate fluids can significantly shorten seal life.

- Proper Installation Follow manufacturer guidelines for seal installation. Improper installation can lead to misalignment and premature failure.

Conclusion

In conclusion, Chief hydraulic cylinder seal kits are essential for the efficient and reliable operation of hydraulic systems. Understanding the importance of seals, the components included in seal kits, and proper maintenance practices can help ensure that hydraulic cylinders function optimally for many years. By choosing high-quality seal kits and adhering to maintenance recommendations, operators can significantly reduce downtime and extend the life of their hydraulic equipment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories