Oct . 06, 2024 22:24 Back to list

wiper ring

Understanding Wiper Rings A Key Component in Sealing Technology

Wiper rings are critical components used in various hydraulic, pneumatic, and industrial applications primarily for sealing purposes. These small yet essential parts play a significant role in preventing leakage and ensuring the efficient operation of machinery. Primarily designed for use in cylinders and pistons, wiper rings are often constructed from materials that accommodate a range of environmental conditions, making them versatile for different applications.

One of the primary functions of a wiper ring is to keep contaminants such as dirt, dust, and moisture from entering the hydraulic or pneumatic systems. This is crucial because any foreign particles can cause wear and tear on seals, leading to premature failure and increased maintenance costs. By acting as a first line of defense, wiper rings help maintain the integrity of the system and extend the lifespan of other sealing components.

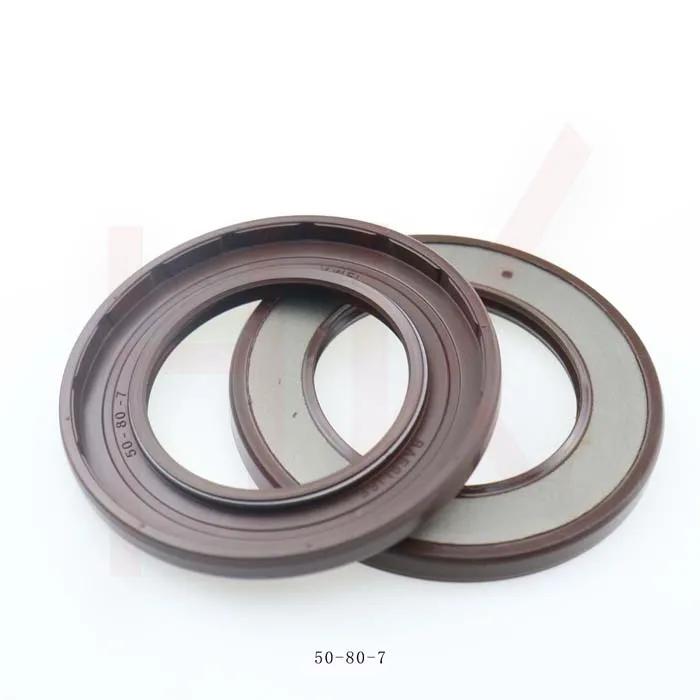

The design of wiper rings is typically influenced by the specific requirements of the application

. For instance, they can come in various shapes, sizes, and profiles, with some featuring added lip or sealing technology to enhance their effectiveness. Commonly used materials include elastomers, polyurethane, and PTFE (polytetrafluoroethylene), which provide excellent resistance to wear, temperature fluctuations, and chemical exposure. This adaptability allows them to function well in diverse environments, from heavy machinery to delicate instruments.wiper ring

In hydraulic systems, for example, wiper rings ensure that hydraulic fluid does not escape, which maintains system pressure and efficiency. Meanwhile, in pneumatic systems, they help prevent air leakage, thereby supporting optimal performance and energy efficiency. Proper installation and selection of wiper rings are vital; the wrong size or material can lead to system malfunctions or reduced performance.

Furthermore, wiper rings contribute not only to the functionality of machinery but also to safety. For instance, in automotive applications, effective wiper rings can prevent fluid leaks that might lead to hazardous situations. Therefore, investing in high-quality wiper rings can significantly impact overall system reliability.

In conclusion, wiper rings are indispensable in various mechanical systems, contributing to efficiency, longevity, and safety. As technology continues to advance, the development of new materials and designs will likely enhance their performance even further. Understanding the importance of these components allows industries to maintain their equipment better, reduce downtime, and save costs in the long run. Whether in manufacturing, automotive, or other sectors, the role of wiper rings cannot be overstated.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories