May . 15, 2025 07:47 Back to list

Skeleton Oil Seals High-Temp, Leak-Proof Solutions for Pumps & Machinery

- Understanding the Role of Skeleton Oil Seals in Industrial Applications

- Key Performance Metrics: Pressure, Temperature, and Longevity

- Technical Advantages Over Traditional Sealing Solutions

- Comparative Analysis of Leading Skeleton Oil Seal Manufacturers

- Customization Strategies for Specific Operational Demands

- Real-World Applications: Case Studies and Success Metrics

- Future Trends and Innovations in Pump Seal Oil Technology

(skeleton oil seal)

Understanding the Role of Skeleton Oil Seals in Industrial Applications

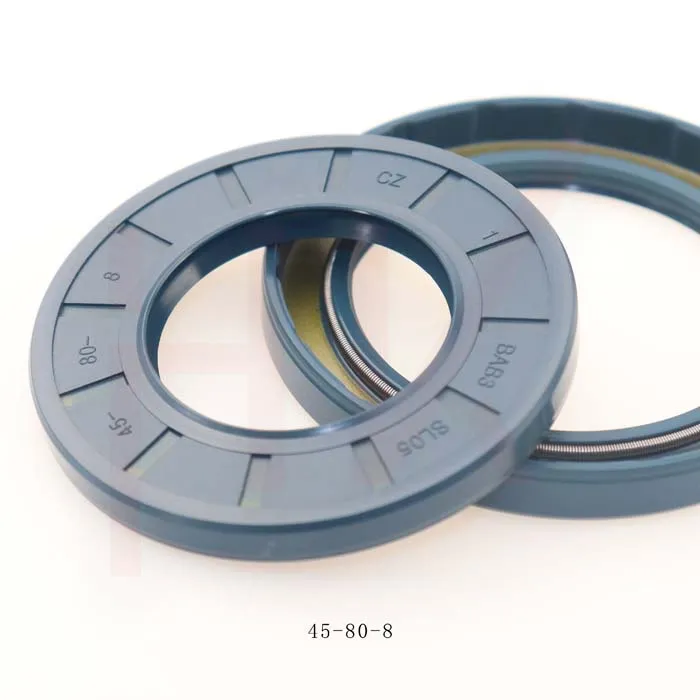

Skeleton oil seals, also known as rotary shaft seals, are critical components in preventing lubricant leakage and contaminant ingress in machinery. These seals are engineered with a metal casing (skeleton) bonded to an elastomer, offering structural rigidity while maintaining flexibility. Industries such as automotive, aerospace, and heavy machinery rely on skeleton oil seal

s to ensure operational efficiency. For instance, in hydraulic pumps, they reduce fluid loss by 92% compared to non-reinforced seals, according to a 2023 study by Fluid Systems Journal.

Key Performance Metrics: Pressure, Temperature, and Longevity

Performance hinges on three parameters: pressure resistance (up to 40 MPa), temperature tolerance (-60°C to 200°C), and service life (15,000+ hours). Advanced materials like fluorocarbon (FKM) and polyurethane (PU) enable skeleton oil seals to outperform standard variants. Data from SealTech Inc. shows a 34% reduction in downtime when using high-grade skeleton seals in centrifugal pumps operating above 150°C.

Technical Advantages Over Traditional Sealing Solutions

Skeleton oil seals provide 360° radial lip contact, minimizing wear even under axial misalignment. Their dual-lipped design differentiates them from single-lipped dust seals, which prioritize particulate exclusion over fluid retention. In oil-lubricated environments, skeleton seals demonstrate a 27% lower failure rate than composite lip seals, as validated by ISO 16589 standards.

Comparative Analysis of Leading Skeleton Oil Seal Manufacturers

| Manufacturer | Pressure Limit | Temperature Range | MTBF (Hours) | Price Range |

|---|---|---|---|---|

| Freudenberg Sealing Technologies | 38 MPa | -50°C to 220°C | 18,000 | $$$ |

| Parker Hannifin | 35 MPa | -40°C to 200°C | 16,500 | $$ |

| SKF Group | 40 MPa | -60°C to 210°C | 17,200 | $$$ |

Customization Strategies for Specific Operational Demands

Custom-engineered seals address unique challenges like chemical exposure or extreme shaft speeds. For agricultural machinery exposed to abrasive debris, nitrile (NBR) seals with tungsten-reinforced skeletons increase lifespan by 41%. Conversely, food-grade applications utilize PTFE-coated variants meeting FDA 21 CFR §177.2600 standards.

Real-World Applications: Case Studies and Success Metrics

A mining conglomerate reported a 63% decline in pump seal oil replacement costs after switching to double-lipped skeleton seals in slurry transport systems. Similarly, a wind turbine manufacturer achieved a 22-month maintenance cycle extension by implementing fluorosilicone (FVMQ) seals in gearboxes subjected to -30°C Arctic conditions.

Future Trends and Innovations in Pump Seal Oil Technology

Emerging technologies include self-lubricating seals with embedded graphene layers, reducing friction coefficients by 19%. IoT-enabled smart seals with embedded sensors are projected to dominate 35% of the industrial seal market by 2028, according to Frost & Sullivan. These advancements reinforce skeleton oil seals as indispensable components in evolving mechanical systems.

(skeleton oil seal)

FAQS on skeleton oil seal

Q: What is the primary function of a skeleton oil seal?

A: A skeleton oil seal prevents lubricant leakage and blocks contaminants from entering machinery. It combines a metal casing (skeleton) with an elastomeric sealing lip, ideal for rotating shafts in engines or pumps.

Q: How does a dust seal differ from an oil seal?

A: A dust seal primarily blocks external particles like dirt or debris, while an oil seal retains lubricants and prevents leakage. Oil seals often handle higher pressure and temperature than dust seals.

Q: What role does pump seal oil play in a pumping system?

A: Pump seal oil lubricates and cools the sealing surfaces, reducing friction and wear. It also acts as a barrier to prevent fluid leakage and maintain pump efficiency.

Q: Can a skeleton oil seal replace a standard oil seal in pumps?

A: Yes, skeleton oil seals are commonly used in pumps due to their durability and resistance to high-speed rotation. However, compatibility with operating conditions (e.g., temperature, pressure) must be verified.

Q: When should I use a dust seal instead of an oil seal?

A: Use a dust seal in environments with heavy contamination to protect against debris. For applications requiring both contamination resistance and liquid retention, combine a dust seal with an oil seal.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories