Dec . 25, 2024 00:09 Back to list

Exploring Innovations in Oil Hub Seals for Enhanced Performance and Reliability

The Importance of Oil Hub Seals in Modern Industry

In the world of petroleum and gas extraction, the efficiency and safety of operations are paramount. One often-overlooked component that plays a crucial role in ensuring these aspects is the oil hub seal. As the industry evolves, understanding the function and significance of oil hub seals becomes increasingly critical for businesses and engineers alike.

What are Oil Hub Seals?

Oil hub seals are mechanical components used to prevent the escape of lubricant or oil from machinery and to protect these systems from external contaminants such as dirt, dust, and water. They are commonly employed in various equipment, including pumps, gearboxes, and engines, especially within the oil and gas sector. Their primary function is to maintain a clean and efficient environment within the machinery, prolonging its life and improving performance.

The Role of Oil Hub Seals in Equipment Performance

The continuous operation of machinery in the oil and gas industry is crucial for achieving productivity goals. Oil hub seals contribute to this by ensuring that lubrication remains intact. Effective lubrication reduces friction and wear on components, which can lead to equipment failure if not maintained. A significant amount of machinery downtime can be attributed to seal failures, resulting in costly repairs and lost production time.

Furthermore, oil hub seals help maintain the optimal operating temperature of equipment. Overheating can severely impact the efficiency of mechanical systems, and effective sealing ensures that lubricants remain in place to dissipate heat effectively. By managing lubrication and temperature control, oil hub seals directly contribute to the operational efficiency of the equipment.

The Safety Aspect of Oil Hub Seals

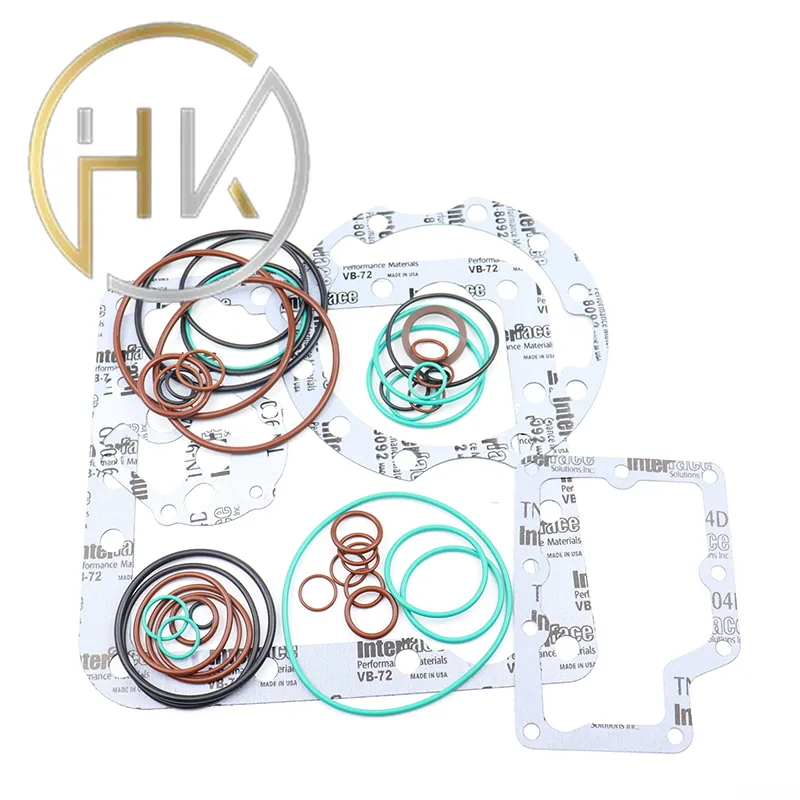

oil hub seal

In addition to enhancing performance, oil hub seals are vital for safety in the oil and gas sector

. The machinery used in extraction and processing is subject to high pressures and potentially hazardous materials. Inadequate sealing can lead to leaks, resulting in not only environmental damage but also risks to human safety.The failure of a seal can lead to catastrophic outcomes, including explosions or oil spills, both of which have severe implications for public health and the environment. Therefore, ensuring the integrity of oil hub seals is not just a matter of operational efficiency but a critical safety concern. Regular maintenance and inspection of seals can prevent leaks and ensure compliance with safety regulations.

Innovations in Oil Hub Seal Technology

Advancements in technology have led to the development of more durable and efficient oil hub seals. Traditional materials are increasingly being replaced with advanced polymers and composite materials that offer superior resistance to harsh chemicals and extreme operating conditions. This enhancement allows seals to maintain their integrity over longer periods, reducing the frequency of replacements and the cost associated with maintenance.

Moreover, smart sealing technologies are emerging, incorporating sensors that monitor the performance of seals in real time. These innovations provide valuable data that can help predict failures before they occur, allowing for proactive maintenance and reducing the risk of unexpected downtime.

Conclusion

In the ever-evolving world of oil and gas, the significance of oil hub seals cannot be underestimated. They play a crucial role in maintaining equipment performance, ensuring safety, and optimizing operational efficiency. As technology continues to advance, the ability to produce seals that withstand the rigors of the industry while providing real-time monitoring and analytics will likely become a game-changer.

Businesses that prioritize the quality of their oil hub seals and invest in innovative solutions will not only enhance their operational efficiency but also ensure a safer work environment. In an industry where margins can be thin and the stakes high, understanding the importance of every component—especially something as seemingly minor as an oil hub seal—can make all the difference between success and failure.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories