Mar . 06, 2025 11:06 Back to list

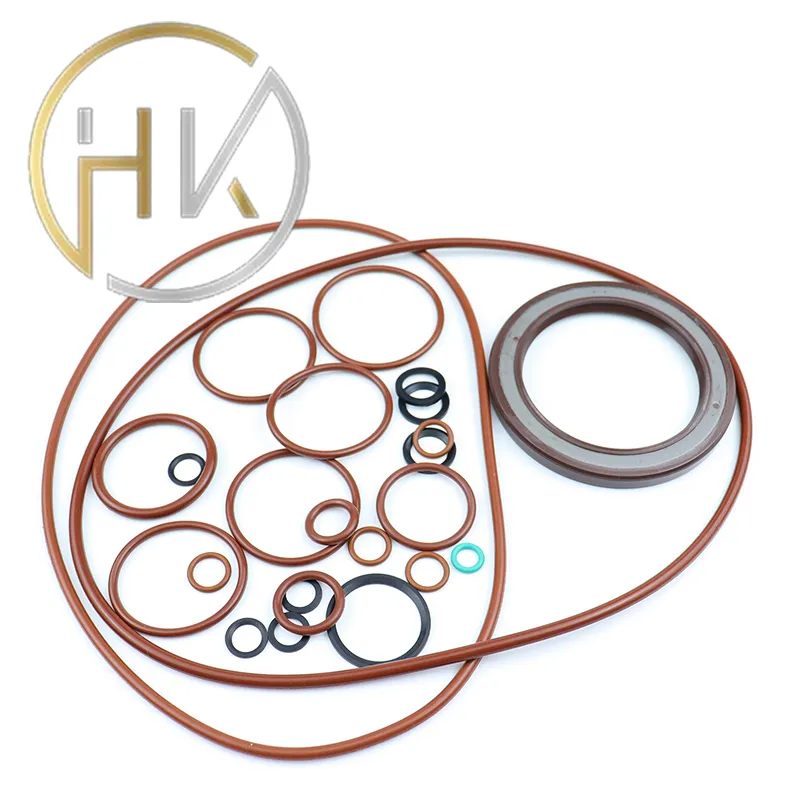

17x40x7 seal

Moreover, the application of advanced technologies in the manufacturing process of 17x40x7 seals promises even greater enhancements. Innovations in material science have led to seals capable of enduring higher pressure thresholds and broader temperature ranges. This adaptability further cements their place as a go-to solution for industries grappling with evolving operational demands. Feedback from the field has continually verified the benefits of incorporating these seals into standard maintenance protocols. Regular audits and inspections should include assessments of the seal’s condition, facilitating early detection of wear or potential failure. This proactive approach can preempt costly downtimes and ensure seamless industrial processes. Industries such as automotive and aerospace, where precision and dependability cannot be compromised, have increasingly come to rely on the efficacy of the 17x40x7 seal. Their integration into daily operations underscores a fundamental shift towards utilizing components that offer high levels of assurance against mechanical failure. In conclusion, the 17x40x7 seal is an embodiment of engineering excellence, trusted for its superior sealing capabilities across a range of complex applications. Industry professionals who prioritize efficiency, safety, and longevity in machinery will find these seals an invaluable asset. Their role in mitigating operational risks and enhancing machinery reliability makes them a cornerstone in modern industrial maintenance. Investing in these seals is not just a choice but a definitive step towards achieving sustainable operational excellence.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories