Dhj . 29, 2024 01:57 Back to list

rotary shaft oil seals

Understanding Rotary Shaft Oil Seals Function, Types, and Applications

Rotary shaft oil seals, often referred to simply as oil seals or rotary seals, are critical components used in various mechanical systems. Their primary purpose is to prevent the leakage of lubricating oils and greases while keeping contaminants out of the machinery. This function is essential for maintaining optimal performance and longevity of equipment.

The Function of Rotary Shaft Oil Seals

Oil seals serve a vital role in rotating machinery such as engines, pumps, and gearboxes. They help to maintain a pressure differential, preventing oil from leaking out of the housing and keeping dirt, dust, moisture, and other foreign particles from entering. This is particularly important in environments where equipment operates under high pressure or in dirty conditions.

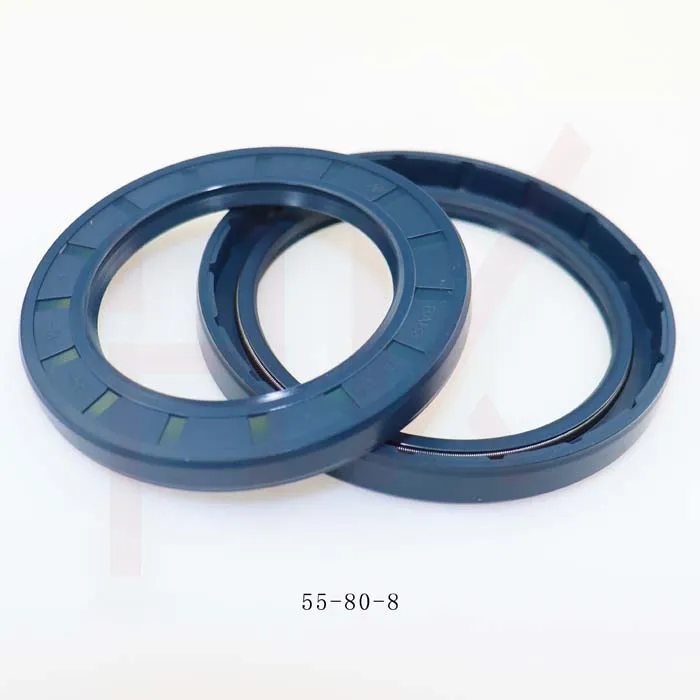

A rotary shaft oil seal consists of a flexible sealing lip that presses against a rotating shaft, creating a tight seal. This lip is usually made from rubber or elastomeric materials designed to withstand the specific conditions of the application, including temperature variations and exposure to different chemicals.

Types of Rotary Shaft Oil Seals

There are various types of rotary shaft oil seals, each designed for specific applications. The most common types include

1. Single Lip Seals These are the simplest and most widely used type. They have one sealing lip that closes against the shaft. Single lip seals are effective in applications with low-pressure requirements.

2. Double Lip Seals Featuring two sealing lips, double lip seals provide an additional layer of protection against contaminants. They are ideal for high-performance applications and environments exposed to more severe conditions.

3. Spring-loaded Seals These seals incorporate a spring that helps maintain constant contact between the sealing lip and the shaft, enhancing sealing performance under varying operating conditions.

4. Metal outer surface seals These seals feature a metal outer casing, providing greater dimensional stability and the ability to withstand higher pressures.

5. Hydraulic Seals These are specialized seals designed for hydraulic applications. They are often built to maintain a seal under high-pressure conditions that are common in hydraulic systems.

Applications of Rotary Shaft Oil Seals

rotary shaft oil seals

Rotary shaft oil seals are used across a diverse range of industries, including

- Automotive In vehicles, oil seals prevent engine oil from leaking, safeguarding engine components. They are commonly found in crankshaft and camshaft applications.

- Aerospace Aircraft engines use oil seals to maintain oil pressure and prevent contamination in highly precise and sensitive systems.

- Industrial Machinery Many manufacturing machines incorporate oil seals to regulate lubrication and protect against external contaminants.

- Agricultural Equipment Tractors and other farming machinery utilize oil seals to ensure efficient operation under harsh conditions.

Choosing the Right Oil Seal

Selecting the appropriate rotary shaft oil seal for a specific application involves considering various factors

- Operating Conditions Temperature, pressure, and exposure to chemicals or contaminants should be assessed to choose a seal material that can withstand these conditions.

- Shaft Diameter and Surface Finish The size and finish of the shaft will dictate the required diameter and tolerance of the seal.

- Operational Speed The rotational speed of the shaft can affect the performance of the oil seal. Higher speeds tend to generate more heat, which may require specific seal designs.

- Installation Type Some seals are designed to fit into specific housings or require particular installation methods. It is crucial to consider these factors to ensure a proper fit and function.

Conclusion

Rotary shaft oil seals are fundamental in ensuring the reliability and efficiency of mechanical systems across various industries. Understanding the different types, functions, and applications can help in selecting the right seal for each specific need, ultimately contributing to the longevity and operational efficiency of machinery. Proper maintenance and timely replacement of worn seals can prevent costly damage and downtime in industrial operations, making oil seals an essential component in mechanical design and engineering.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories