Dhj . 07, 2024 16:32 Back to list

metric wiper seals

Understanding Metric Wiper Seals Functions, Types, and Applications

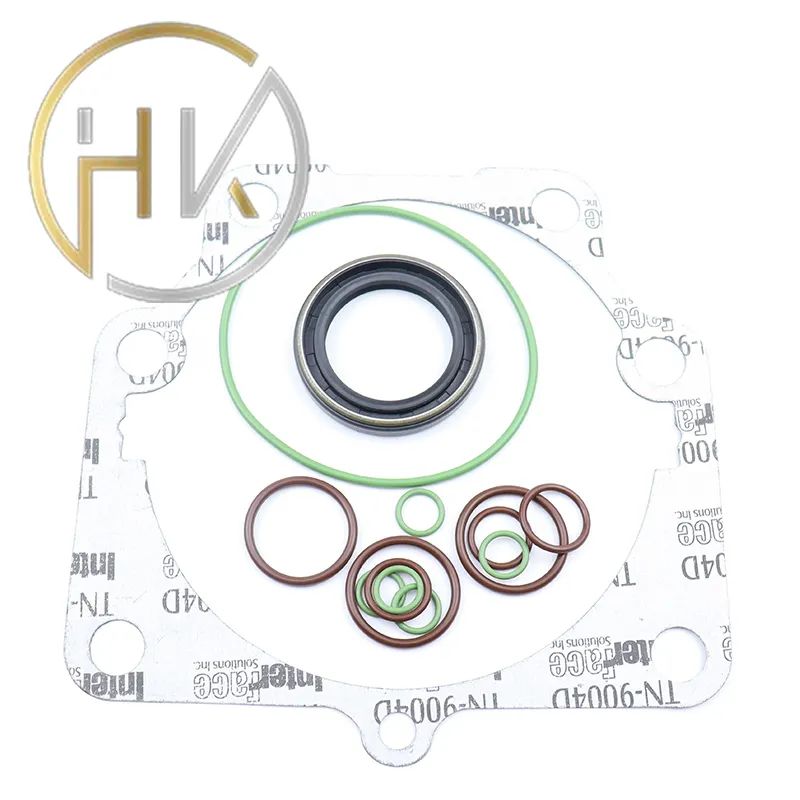

In the world of mechanical engineering and fluid control, the importance of seals cannot be overstated. Among the various types of seals used in hydraulic and pneumatic systems, metric wiper seals play a critical role in ensuring the effective operation and longevity of equipment. These components are designed to prevent foreign particles and contaminants from entering a mechanical system while also protecting the internal components from wear.

What Are Metric Wiper Seals?

Metric wiper seals, also known as rod wipers or dust seals, are specifically engineered to fit metric-sized components in machinery. They are utilized primarily in hydraulic cylinders and pneumatic systems to clean and wipe off dirt, debris, and moisture that may accumulate on the rod as it extends and retracts. Their primary function is to promote a clean working environment within the cylinder and prevent contamination from affecting the operation and integrity of the hydraulic fluid or pneumatic air.

Construction and Materials

The design of metric wiper seals can vary based on their application, but they generally consist of three main components the sealing element, support element, and a back-up element. The sealing element is made typically from elastomers, such as nitrile rubber, polyurethane, or Viton, which are known for their excellent resistance to wear, temperature fluctuations, and chemical exposure. The support element tends to be rigid, providing stability to the seal, while the back-up element may offer additional dimensional support to prevent extrusion under high pressure.

Types of Metric Wiper Seals

There are several types of metric wiper seals to cater to various applications

1. Single Acting Wipers These seals wipe in one direction only and are suitable for applications where the rod extends out but does not retract back through the wiper.

2. Double Acting Wipers As the name suggests, these seals can wipe in both directions and are appropriate for systems where the rod moves in and out repeatedly, thus providing a more effective cleaning capability.

3. Specialized Wipers Some designs incorporate features that enhance their performance, such as lips or grooves that further improve their sealing abilities against dirt and moisture ingress.

metric wiper seals

Applications of Metric Wiper Seals

Metric wiper seals are a vital component in numerous industries, including

- Construction Machinery Equipment like excavators, backhoes, and loaders rely heavily on reliable hydraulic systems that require stringent sealing solutions to prevent premature wear and tear.

- Automotive Industry In vehicles, metric wiper seals play a role in ensuring the durability of hydraulic components in brakes and power steering systems.

- Manufacturing Machinery used in production lines depends on seals to maintain efficiency and minimize downtime caused by leaks or blockages.

- Aerospace The aerospace sector utilizes wiper seals in hydraulic systems of aircraft to ensure safety and reliability during operations.

Importance of Choosing the Right Wiper Seal

Selecting the appropriate metric wiper seal is crucial for maintaining the efficiency and lifespan of any machinery. Factors to consider when choosing a wiper seal include the size and type of machinery, operating environment, temperature ranges, and the type of fluids involved. A correctly fitted and high-quality wiper seal not only enhances the performance of a system but also reduces maintenance costs significantly in the long run.

Conclusion

Metric wiper seals harmonize the delicate balance between functionality and protection in hydraulic and pneumatic systems. Their design, construction, and application across various industries underline their importance in maintaining operational integrity and efficiency. As technology advances and industries evolve, the role of metric wiper seals will continue to be integral in ensuring that machinery operates optimally, safeguarding against contamination, and promoting longevity in equipment performance. Thus, understanding and selecting the right metric wiper seal can have far-reaching implications in achieving both operational excellence and cost-effectiveness.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories