Nën . 08, 2024 06:54 Back to list

Understanding the Functionality and Importance of Hydraulic Ram Seals in Machinery

Understanding Hydraulic Ram Seals Essential Components for Efficient Performance

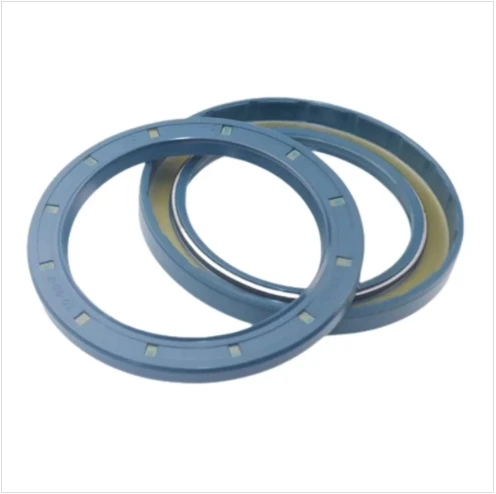

Hydraulic ram seals play a critical role in the functionality and efficiency of hydraulic systems. Found in various applications ranging from construction equipment to automotive systems, these seals are designed to prevent fluid leakage and contamination, ensuring optimal performance and longevity.

What is a Hydraulic Ram Seal?

A hydraulic ram seal is a component that fills the gap between two surfaces in a hydraulic system, typically between a ram and its cylinder. This seal is crucial for maintaining pressure within the hydraulic system, allowing for effective force transmission. Hydraulic rams operate under high pressure, which necessitates robust seals that can withstand extreme conditions such as temperature fluctuations, high pressures, and the potential for abrasive materials.

Types of Hydraulic Ram Seals

Hydraulic ram seals come in various types, each designed for specific applications and requirements

. The most common types include1. O-Rings These circular seals are commonly used due to their simple design and versatility. They can handle a wide range of pressures and temperatures, making them suitable for multiple hydraulic applications.

2. U-Cups U-cup seals are designed to provide a tight fit in hydraulic cylinders, preventing fluid leakage while also reducing friction during operation. Their unique shape allows them to maintain their sealing force even under varying pressures.

3. V-Rings These are utilized in applications where axial forces are present. V-rings are typically made of elastomeric materials, allowing them to fit snugly against the ram and cylinder, effectively sealing the hydraulic fluid while accommodating any slight misalignment.

hydraulic ram seals

4. Rod and Piston Seals These are specialized seals designed for the piston and rod of a hydraulic ram. Rod seals focus on preventing fluid from leaking out, while piston seals are responsible for keeping fluid from entering the cylinder.

Importance of Quality Seals

The quality of hydraulic ram seals directly impacts the overall performance of a hydraulic system. Low-quality seals can lead to leaks, which not only reduces efficiency but can also cause costly downtime and repairs. Additionally, compromised seals can allow contaminants to enter the hydraulic fluid, leading to wear and damage to critical components.

To ensure the longevity and effectiveness of hydraulic ram seals, it is crucial to choose seals made from high-quality materials. Common materials include nitrile rubber (NBR), polyurethane, and fluorocarbon, each offering unique properties suited to various environments.

Maintenance and Replacement

Regular maintenance and inspection of hydraulic ram seals are vital for preventing issues before they arise. Operators should routinely check for signs of wear, such as cracking or hardening, which can indicate that a seal needs replacement. Timely replacement of worn seals not only ensures efficient operation but also prolongs the lifespan of the hydraulic system.

Moreover, during installation and replacement, it’s essential to follow manufacturer specifications to ensure the seals are properly fitted. Incorrect installation can lead to premature failure and the very problems that quality seals are designed to prevent.

Conclusion

Hydraulic ram seals are an integral part of hydraulic systems, serving as the frontline defense against fluid leaks and contamination. By understanding the various types of seals and their importance, operators can make informed choices that enhance the efficiency and reliability of their hydraulic systems. Investing in quality seals and maintaining them properly can lead to improved performance, reduced operational costs, and a longer lifespan for hydraulic equipment.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories