Shk . 15, 2025 02:36 Back to list

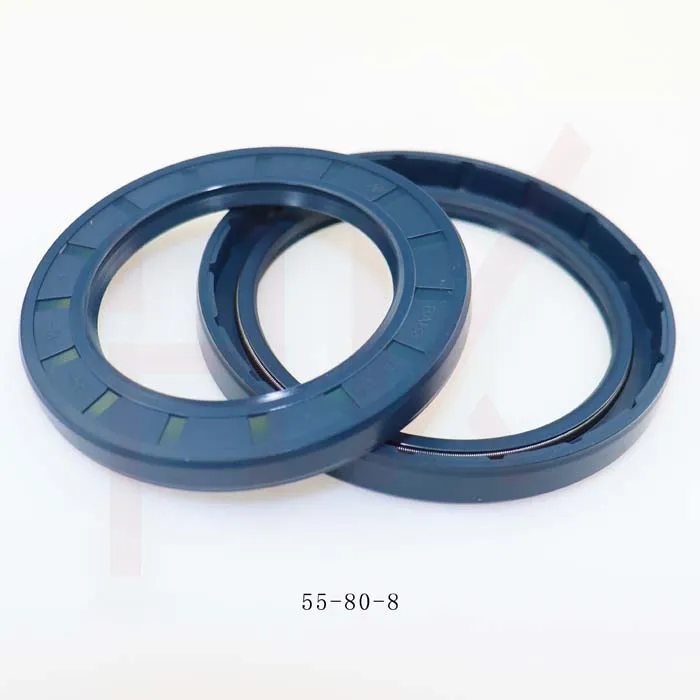

rotary oil seals

From an expertise standpoint, installation and maintenance are key components of maximizing the effectiveness of high pressure rotary shaft seals. Proper installation ensures that the seal is aligned correctly and operates within its designed parameters, thereby preventing premature failure. Regular maintenance checks are equally vital, allowing for the early detection of wear or damage, which, if left unaddressed, could lead to costly downtime or equipment failure. Training of maintenance staff in the latest inspection techniques and replacement protocols is essential for businesses aiming to keep their operations running smoothly. In terms of authoritativeness, leading seal manufacturers often publish extensive technical guides and offer professional consultation services. These resources are invaluable for engineers and procurement specialists tasked with specifying seals for new or existing applications. Such documents typically include detailed information on pressure ratings, temperature limits, and installation procedures, helping ensure that every factor is considered during the selection process. Trustworthiness in the context of high pressure rotary shaft seals is built through a combination of proven performance, quality certifications, and a commitment to ongoing innovation. Manufacturers that invest heavily in research and development demonstrate a dedication to improving seal performance and reliability, thus earning the confidence of their clients. Furthermore, companies that adhere to international quality standards such as ISO 9001 bolster their reputation as reliable partners in the industrial sector. For companies looking to optimize their use of high pressure rotary shaft seals, investing in high-quality products and prioritizing regular training and maintenance are paramount. With the right combination of expertise, advanced materials, and cutting-edge technology, these small yet powerful components will continue to play an essential role in maintaining the efficiency and reliability of industrial machinery across a multitude of sectors.

-

DKBI Hydraulic Wiper Seal 20x32x6/9 | Dustproof & Standard Oil Seal

NewsAug.30,2025

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

NewsAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

Products categories