Nën . 04, 2024 22:46 Back to list

25x35x7 oil seal

Understanding the 25x35x7% Oil Seal A Guide to Its Importance and Applications

Oil seals, also known as mechanical seals or hydraulic seals, play a crucial role in various machinery and equipment by preventing leakage of lubricants or hydraulic fluids from one compartment to another. One such oil seal that is widely used in various applications is the 25x35x7 oil seal. This article will delve into the specifications, significance, applications, and maintenance tips regarding the 25x35x7 oil seal.

Specifications of the 25x35x7 Oil Seal

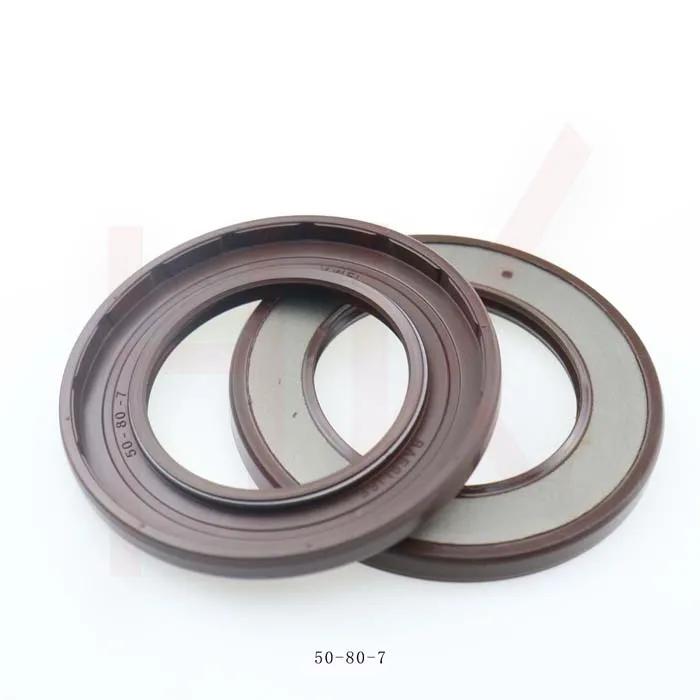

The designation 25x35x7 refers to the dimensions of the oil seal in millimeters. Specifically, the first number (25) represents the inner diameter of the seal, the second number (35) represents the outer diameter, and the last number (7) indicates the thickness of the seal. These dimensions are critical in ensuring that the oil seal fits perfectly in its designated housing, thereby preventing fluid leakage.

The oil seal is typically made from durable materials such as rubber, polyurethane, or silicone. These materials are selected for their resilience against various chemicals, heat, and wear and tear, making them suitable for demanding industrial environments. Some 25x35x7 oil seals may also feature a lip design, which enhances their ability to retain lubricants and prevent contaminants from entering mechanical components.

Importance of Oil Seals

The primary purpose of an oil seal like the 25x35x7 is to maintain the integrity of fluids within mechanical systems. In engines, for instance, oil seals are essential for preventing engine oil from leaking out and protecting the engine from dirt and other unwanted particles. This is vital for maintaining lubrication, which helps in reducing friction and wear on moving parts.

Furthermore, the effectiveness of an oil seal in preventing leakage directly impacts the efficiency of machinery. A leaking seal can lead to a loss of lubricants, reduced operational efficiency, and increased wear on components. In severe cases, it may result in equipment failure, leading to costly repairs and downtime.

Applications of the 25x35x7 Oil Seal

The versatility of the 25x35x7 oil seal allows it to be used in various industries and applications. Some of the common applications include

1. Automotive Industry In vehicles, oil seals are utilized in engines, transmissions, and differentials. They help in keeping the engine oil contained and free from contaminants, ensuring optimal performance.

25x35x7 oil seal

2. Industrial Machinery Many industrial machines, such as pumps and motors, require reliable sealing solutions to protect against fluid leakage. The 25x35x7 oil seal is often found in hydraulic systems, conveyor systems, and gearboxes.

3. Home Appliances Oil seals are also prevalent in various home appliances, including refrigerators and washing machines, where they help in preventing fluid leaks that could cause damage or reduce efficiency.

4. Aerospace and Marine Applications In aerospace and marine environments, oil seals are crucial for maintaining integrity under extreme conditions. The 25x35x7 seal is used in hydraulic systems and other applications where reliability is paramount.

Maintenance Tips

To ensure the longevity and effectiveness of the 25x35x7 oil seal, proper maintenance is essential. Here are some tips

- Regular Inspection Periodically check for signs of leaks or wear and tear. Address any issues promptly to prevent further damage.

- Proper Installation Follow manufacturer guidelines during installation. Ensuring a proper fit is crucial for the oil seal's performance.

- Use Compatible Fluids Make sure that the fluids used in the machinery are compatible with the oil seal material to prevent deterioration.

- Monitor Operating Conditions Keep an eye on temperature and pressure conditions, as extreme variations can affect the seal's performance.

In conclusion, the 25x35x7 oil seal is an essential component in numerous applications, ensuring the reliability and efficiency of various machinery. Understanding its specifications, significance, and maintenance can help maximize its lifespan and optimize equipment performance. Whether in automotive, industrial, or household applications, the proper use and maintenance of oil seals can lead to significant benefits in operational efficiency and cost savings.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories