Oct . 31, 2024 20:02 Back to list

Hydraulic Rod Wiper Seal Design and Performance Considerations for Enhanced Sealing Efficiency

Understanding Hydraulic Rod Wiper Seals

Hydraulic systems are vital in various applications, from heavy machinery to automotive technologies. A crucial component within these systems is the hydraulic rod wiper seal, which plays an essential role in maintaining the efficiency and longevity of hydraulic cylinders. Understanding the function and importance of wiper seals can help in ensuring optimal performance in hydraulic operations.

The primary function of a hydraulic rod wiper seal is to prevent contaminants such as dirt, dust, and moisture from entering the hydraulic cylinder. This is especially important in applications where the cylinder is exposed to harsh conditions. Contaminants can cause significant damage to the internal components of the hydraulic system, leading to wear and tear, malfunctions, and ultimately costly repairs.

Wiper seals are typically positioned at the outer diameter of the hydraulic cylinder, acting as a barrier against external debris. They are designed to fit snugly around the rod, creating a seal that keeps contaminants out while allowing the hydraulic fluid to flow smoothly within the cylinder. The effectiveness of this seal is crucial, as even minor ingress of contaminants can lead to significant problems over time.

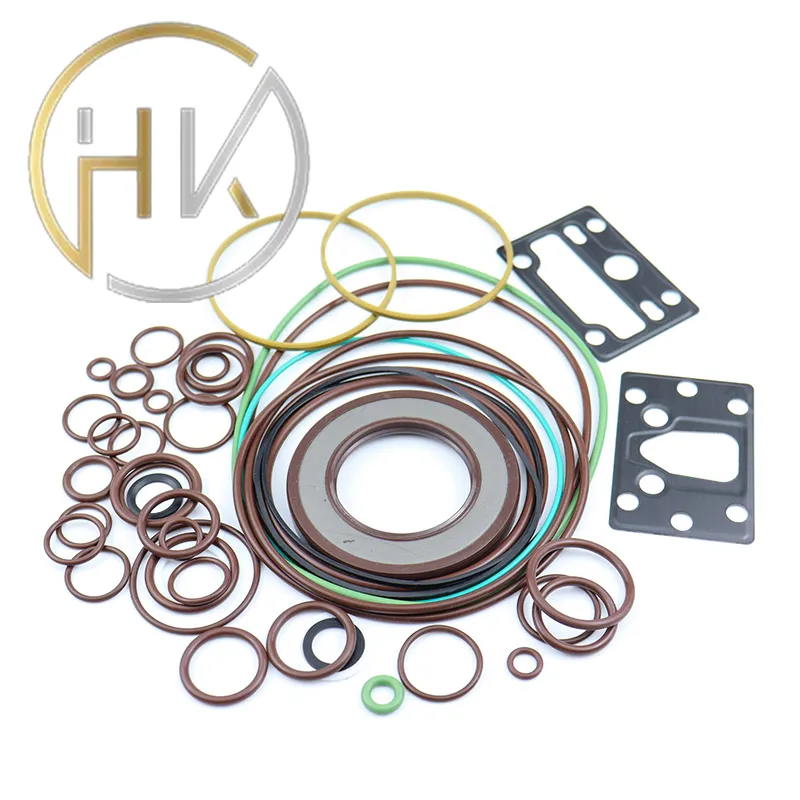

hydraulic rod wiper seal

Several materials are used in the manufacturing of hydraulic rod wiper seals, including polyurethane, nitrile, and rubber. Each material has specific properties that make it suitable for different environments and applications. For example, polyurethane seals are known for their excellent abrasion resistance and durability, making them ideal for high-wear conditions. On the other hand, nitrile seals provide good resistance to oil and are often used in applications involving hydraulic fluids.

Regular maintenance of hydraulic rod wiper seals is essential for the longevity of hydraulic systems. It is advisable to inspect seals periodically for signs of wear or damage. Any compromised seals should be replaced promptly to prevent contaminants from entering the hydraulic cylinder. Additionally, operators should ensure that the surrounding environment is as clean as possible to reduce the risk of contamination.

In conclusion, hydraulic rod wiper seals are integral to the functionality and reliability of hydraulic systems. By preventing contamination, these seals protect hydraulic components and ensure smooth operation. Understanding the importance of these seals and conducting regular maintenance can significantly enhance the performance and durability of hydraulic machinery. As technology continues to advance, ongoing developments in materials and design will likely lead to even more effective wiper seals, further improving the resilience of hydraulic systems in various industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories