Oct . 30, 2024 19:23 Back to list

shaft dust seal

Understanding Shaft Dust Seals Essential Components for Equipment Longevity

Shaft dust seals are critical components used in a variety of mechanical systems, playing a vital role in maintaining the integrity and longevity of machinery. These seals provide a barrier between the rotating shaft and the external environment, preventing dust, dirt, and other contaminants from entering sensitive areas of a machine. As industries increasingly prioritize efficiency and reliability, the importance of effective dust sealing cannot be overstated.

The primary function of a shaft dust seal is to protect the bearings and internal components of a machine from abrasive contaminants. In many applications, particularly in manufacturing and heavy machinery, exposure to dust and debris can lead to accelerated wear and tear. This wear can result in costly downtime for repairs, decreased efficiency, and even catastrophic failures. By effectively sealing the gap around the shaft, dust seals create a controlled environment that extends the life of bearings and other critical components.

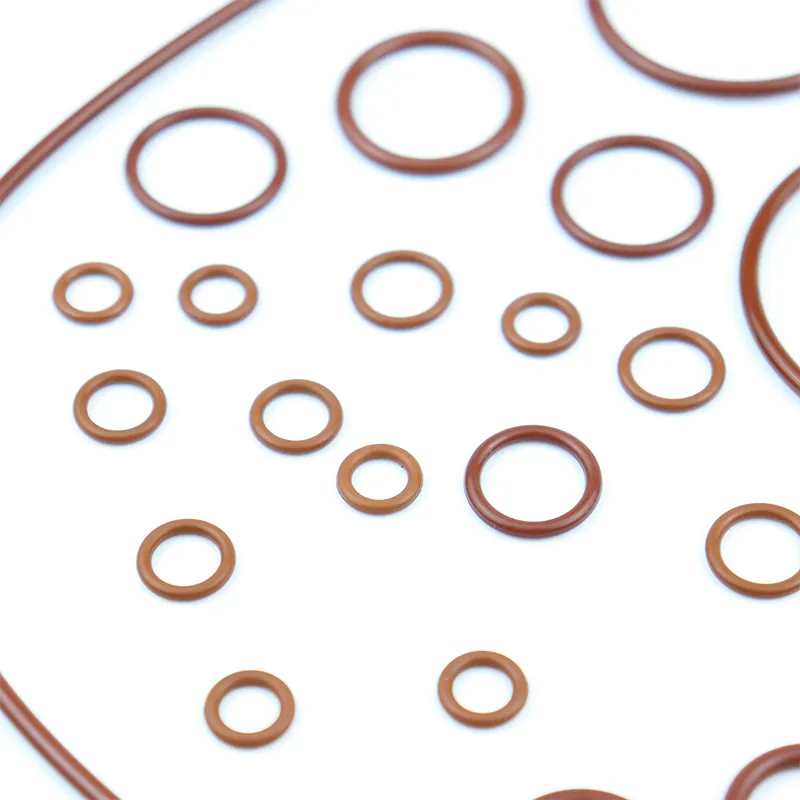

Shaft dust seals come in various designs and materials, tailored to meet the needs of specific applications. Common materials include rubber, polyurethane, and metal, each offering unique advantages such as flexibility, durability, and resistance to chemicals. The choice of material often depends on the operational environment, including factors such as temperature fluctuations, exposure to chemicals, and the presence of moisture.

shaft dust seal

Installation of shaft dust seals is an aspect that should not be overlooked. Proper alignment and fitting are crucial to ensure the effectiveness of the seal. An improperly installed seal can lead to leakage or failure, negating its intended purpose. Regular maintenance and inspections can also help ensure that these seals are functioning correctly, allowing for early identification of wear or damage.

In addition to protecting machinery, shaft dust seals contribute to overall operational efficiency. By preventing contamination, they help maintain optimal lubrication within the machinery, reducing friction and energy consumption. This efficiency not only boosts productivity but also aligns with modern goals of sustainability and resource conservation.

In conclusion, shaft dust seals are essential components that play a significant role in the functionality and longevity of machinery across various industries. Their ability to protect against contamination, coupled with proper installation and maintenance practices, ensures that equipment operates at peak performance. As technology continues to advance, the evolution of shaft dust seal designs will undoubtedly enhance their effectiveness, further contributing to the reliability and efficiency of critical machinery in our increasingly industrialized world.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories