Oct . 20, 2024 07:03 Back to list

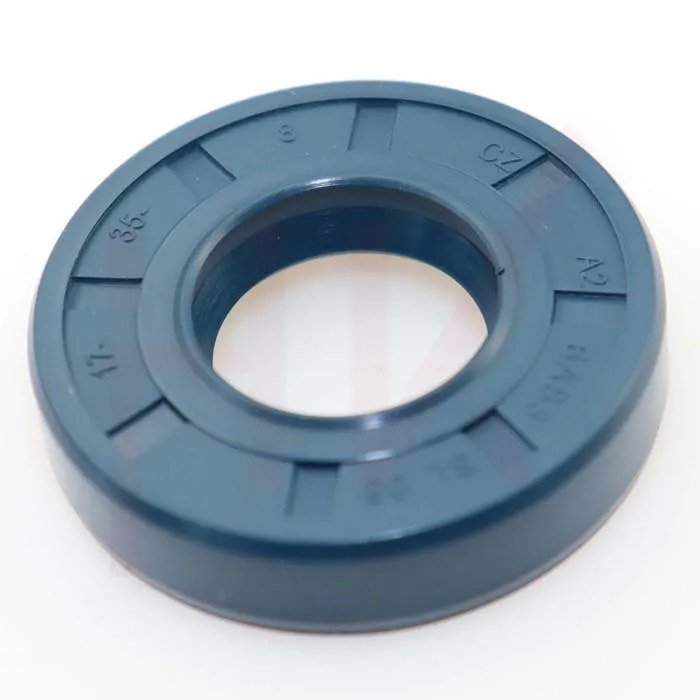

piston wiper ring

Understanding Piston Wiper Rings Function and Importance in Engine Performance

Piston wiper rings, an essential component in the design of internal combustion engines, play a crucial role in the overall performance and efficiency of the engine. Although they may often go unnoticed, these rings are integral to maintaining the ideal environment for the operation of the engine, affecting both its longevity and functionality.

What are Piston Wiper Rings?

Piston wiper rings, also known as scraper rings, are a type of piston ring mounted on the piston in an engine. Their primary function is to clear excess oil from the cylinder wall and ensure that the combustion chamber remains free from oil contamination. Positioned above the compression rings, wiper rings serve as a barrier, preventing oil from entering the combustion space while allowing for the necessary lubrication of the cylinder walls.

How Piston Wiper Rings Work

As the piston moves up and down within the cylinder, the wiper ring interacts with the cylinder wall, scraping away any excess oil that may have accumulated. This process is crucial because if excess oil were to enter the combustion chamber, it could lead to several issues, such as increased emissions, poor engine performance, and even engine knocking. The wiper ring, thus, facilitates a clean separation between the oil lubrication system and the combustion process, allowing for optimal engine operation.

Importance of Piston Wiper Rings

1. Controlling Oil Consumption One of the primary roles of the piston wiper ring is to control oil consumption within the engine. By efficiently scraping excess oil away, these rings minimize the amount of oil that gets burned during combustion, thereby enhancing fuel efficiency and reducing the frequency of oil changes.

piston wiper ring

2. Maintaining Engine Cleanliness The presence of excessive oil in the combustion chamber can contribute to carbon buildup and other deposits, which may lead to engine wear and reduced efficiency over time. Piston wiper rings help mitigate this risk, ensuring that the engine remains clean and operates effectively.

3. Improving Engine Performance With less oil contamination in the combustion chamber, the fuel-air mixture can burn more efficiently, resulting in improved power output and throttle response. This enhancement in performance is crucial for optimizing the engine's overall effectiveness, especially in high-performance applications.

4. Extending Engine Life By maintaining the proper lubrication levels and preventing oil-related issues, piston wiper rings contribute to the longevity of the engine. Reducing the risk of premature wear and tear means that engines can operate effectively for a more extended period, ultimately leading to lower maintenance costs and increased reliability.

Materials and Design Considerations

Piston wiper rings are designed from various materials, including cast iron, steel, and polymer composites, selected based on their ability to withstand high temperatures and pressures. The ring's design is equally important, with shapes and surface textures engineered to enhance their scraping ability and reduce friction against the cylinder wall.

Conclusion

In summary, piston wiper rings, while often overlooked, are vital components of internal combustion engines. Their role in controlling oil consumption, maintaining engine cleanliness, improving performance, and extending engine life cannot be overstated. As technology advances, the materials and designs of these rings continue to evolve, contributing to enhanced engine efficiency and performance. Understanding the significance of wiper rings is essential for anyone involved in engine maintenance and performance optimization, ensuring that these important components receive the attention they deserve. With the right design, manufacturing, and maintenance practices, piston wiper rings will continue to be a critical part of optimizing engine function for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories