Feb . 18, 2025 12:29 Back to list

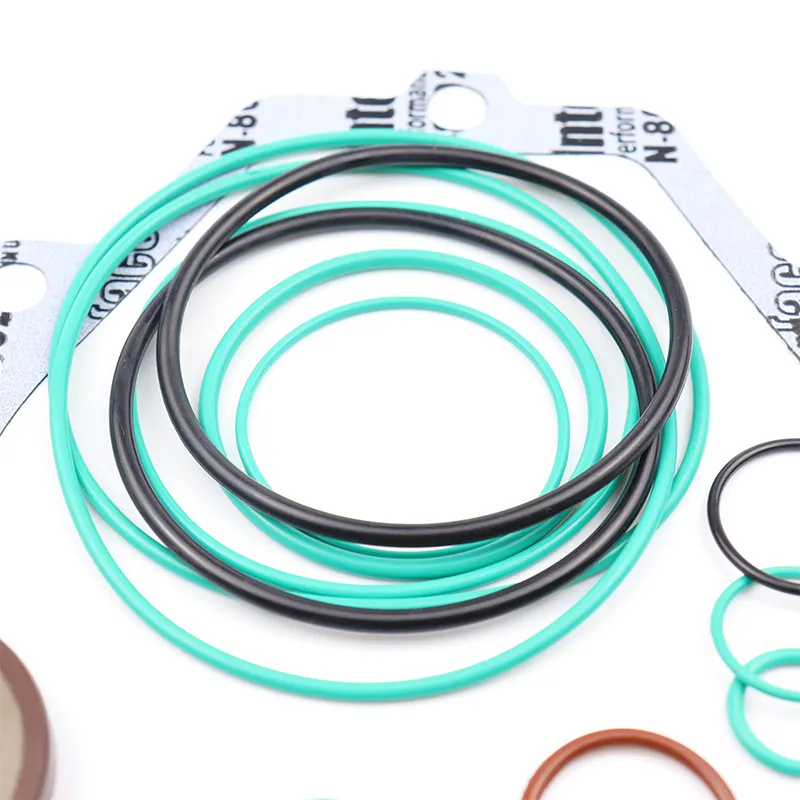

130CC Hydraulic Motor Seal Kit 11095651

Importantly, consistent maintenance is key to the longevity of hydraulic systems. Implementing a routine inspection schedule can help identify potential issues before they escalate into significant problems. Regularly checking for wear and tear, leaks, and performance anomalies involves understanding the signs of hydraulic system distress. This proactive approach can save time and resources, emphasizing the importance of being well-acquainted with your system's nuances. Additionally, possessing a strong understanding of hydraulic systems and repair techniques enhances your ability to execute repairs effectively. There are numerous resources available, from manuals and workshops to online communities, where experienced professionals share insights and tips. Engaging with these resources can expand your knowledge, making you more adept at identifying issues and implementing solutions. Establishing trust with your repair kit provider is another layer of assurance you should not overlook. Reputable suppliers often offer additional guidance on the installation and maintenance of their products. Look for suppliers who provide comprehensive customer support, including detailed installation instructions and after-sales service. A trustworthy provider not only offers quality products but also ensures you have the necessary information and support to achieve optimal outcomes. On a broader scale, embracing sustainable practices in hydraulic system maintenance can further enhance system health. The precision and reliability afforded by high-quality repair kits reduce the likelihood of system failures, minimizing waste. In the long run, this contributes to a more sustainable operational environment, showcasing how attention to detail in component selection aligns with modern sustainability goals. In conclusion, hydraulic cylinder repair kits are invaluable in maintaining and enhancing the performance of hydraulic systems. By selecting quality kits, committing to regular maintenance, and expanding your knowledge, you can significantly improve the efficiency and longevity of these systems. The attention to detail and dedication to quality not only ensure optimal performance but also build reliability and trust in the tools and systems you manage.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories