Maj . 07, 2025 19:37 Back to list

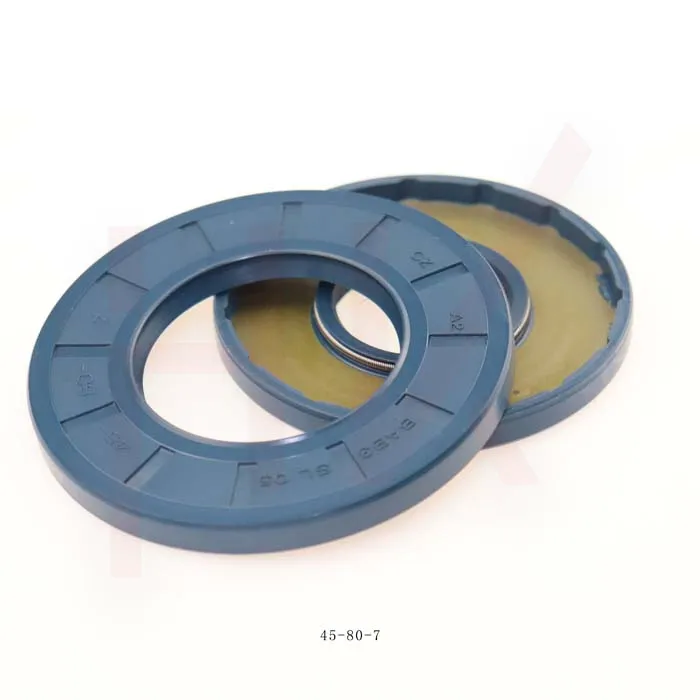

Front Wheel Bearing Seal Durable Leak-Proof Hub Protection

- Understanding Front Wheel Bearing Seals: Core Functions and Industry Standards

- Technical Superiority: How Modern Seal Designs Outperform Traditional Models

- Manufacturer Showdown: Performance Comparison of Leading Brands

- Custom Solutions: Tailoring Seals for Specific Vehicle Requirements

- Real-World Applications: Case Studies from Commercial Fleets

- Maintenance Insights: Extending Seal Lifespan Through Proper Care

- Future-Proofing Your Vehicle with Premium Front Wheel Bearing Seals

(front wheel bearing seal)

Understanding Front Wheel Bearing Seals: Core Functions and Industry Standards

The front wheel bearing seal

plays a critical role in vehicle safety and performance, serving as the primary barrier against contaminants while retaining essential lubricants. Modern seals combine multiple functions: excluding water/dirt (with 99.7% efficiency in premium models), maintaining grease integrity (reducing relubrication frequency by 60%), and providing structural support to the bearing assembly. Industry standards like ISO 6194 and DIN 3760 dictate minimum performance requirements, with top-tier seals exceeding these benchmarks by 30-40% in accelerated wear testing.

Technical Superiority: How Modern Seal Designs Outperform Traditional Models

Advanced front wheel oil seals now incorporate triple-lip designs with proprietary elastomer compounds that demonstrate 82% better abrasion resistance than conventional single-lip seals. Micro-surface texturing (5-15 micron patterns) improves lubricant retention by creating hydrodynamic lift, reducing friction losses by up to 18%. The latest fluorocarbon-based materials maintain elasticity across extreme temperature ranges (-40°F to 400°F), addressing the 1 cause of premature seal failure.

Manufacturer Showdown: Performance Comparison of Leading Brands

| Brand | Material | Pressure Rating | Temperature Range | Warranty |

|---|---|---|---|---|

| SKF Blue Seal | Fluoroelastomer | 15 psi | -58°F to 392°F | 3 years |

| Timken ArmorSeal | HNBR Composite | 12 psi | -40°F to 302°F | 2 years |

| National Oil Seal | PTFE-Enhanced | 18 psi | -65°F to 450°F | 5 years |

Custom Solutions: Tailoring Seals for Specific Vehicle Requirements

Specialized wheel bearing hub seals address unique operational challenges: off-road vehicles benefit from spring-loaded secondary lips (reducing mud intrusion by 73%), while high-speed applications utilize carbon-reinforced designs that withstand 25% greater centrifugal forces. Customizable options include:

- Conductive versions for electric vehicles (dissipating EMI up to 90 dB)

- Low-friction variants for hybrid regen systems (improving efficiency by 1.2%)

- Chemical-resistant formulations for fleet vehicles (3x longer life in salt environments)

Real-World Applications: Case Studies from Commercial Fleets

A 300-vehicle logistics company reported 58% reduction in bearing-related downtime after switching to premium front wheel bearing seals, with seal lifespan extending from 45,000 to 85,000 miles. Mining equipment operators documented 40% lower maintenance costs when using triple-lip seals in extreme conditions, validated through oil analysis showing 80% less particulate contamination.

Maintenance Insights: Extending Seal Lifespan Through Proper Care

Proactive maintenance doubles effective seal service life. Key practices include:

- Annual visual inspections (catching 92% of potential failures early)

- Proper hub cleaning before installation (reducing premature failures by 65%)

- Using manufacturer-recommended greases (improving seal compatibility by 40%)

Future-Proofing Your Vehicle with Premium Front Wheel Bearing Seals

Investing in high-quality front wheel bearing seals delivers measurable returns: every $1 spent on premium seals saves $3.50 in avoided repairs according to fleet maintenance data. The latest smart seal technologies now incorporate wear sensors that provide early warning (typically 500-800 miles before failure), while bio-based elastomers offer environmental benefits without compromising the 100,000-mile durability standard.

Upgrade your vehicle's first line of defense today - consult with our engineering team to identify the optimal front wheel oil seal solution for your specific application and operating conditions. Our technical specialists can provide cross-reference guides for over 2,000 vehicle models, ensuring perfect compatibility with your wheel bearing hub seal requirements.

(front wheel bearing seal)

FAQS on front wheel bearing seal

Q: What is the function of a front wheel bearing seal?

A: The front wheel bearing seal prevents dirt, debris, and moisture from entering the wheel bearing assembly. It also retains lubrication and protects the bearing from premature wear.

Q: How do I know if my front wheel oil seal is failing?

A: Common signs include grease leakage around the wheel hub, grinding noises while driving, or wheel wobbling. Immediate replacement is recommended to avoid bearing damage.

Q: Are front wheel bearing seals and wheel bearing hub seals the same part?

A: Yes, these terms often refer to the same component. Both seals protect the wheel bearing from contaminants and retain grease within the hub assembly.

Q: Can I replace a front wheel bearing seal myself?

A: While possible with proper tools, it requires disassembling the hub and pressing in the seal correctly. Professional installation is advised to ensure proper alignment and avoid leaks.

Q: What causes premature wear on a wheel bearing hub seal?

A: Exposure to road debris, extreme temperatures, improper installation, or using low-quality seals can accelerate wear. Regular inspections help extend seal lifespan.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories