Avg . 16, 2024 14:01 Back to list

Effective Dust-Proof Seals for Enhanced Protection and Longevity in Various Applications

The Importance of Dust Proof Seals in Modern Applications

In today’s technologically advanced world, maintaining the integrity of electronic devices, industrial machinery, and various equipment is paramount. One of the key components that contribute significantly to this integrity is the dust proof seal. These seals protect against the intrusion of dust and other particulate matter, ensuring both the longevity and reliability of the products in which they are installed.

What are Dust Proof Seals?

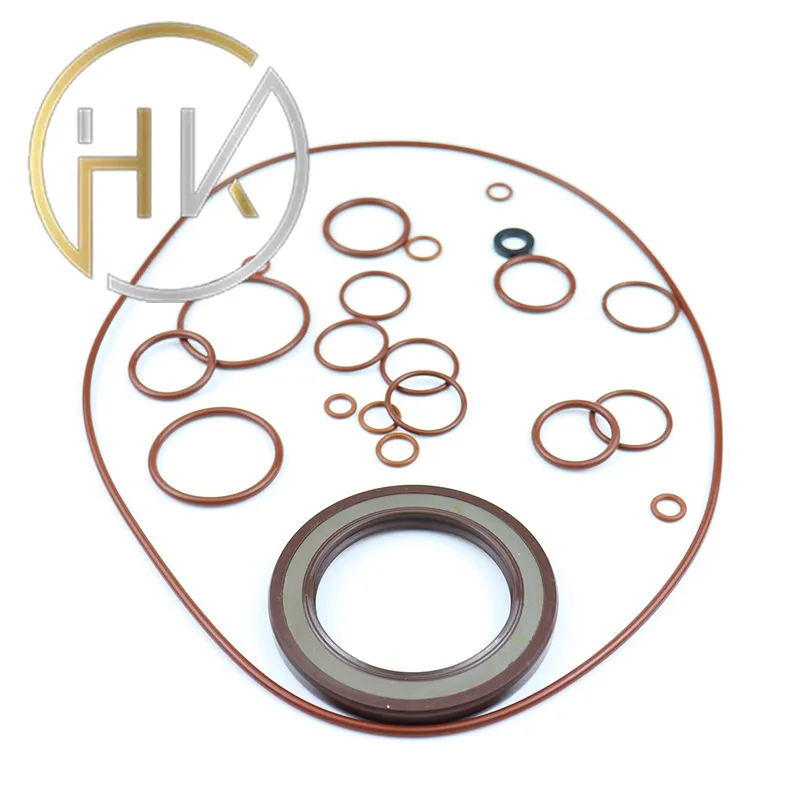

Dust proof seals are specialized components made from various materials such as rubber, silicone, or plastic. They are designed to create a barrier that prevents dust, dirt, and other contaminants from entering sensitive areas of devices. These seals come in different shapes and sizes and can be used in a wide array of applications, ranging from consumer electronics to industrial machinery, automotive systems, and even aerospace technologies.

The Role of Dust Proof Seals

1. Protection Against Contaminants One of the primary roles of dust proof seals is to act as a protective barrier against environmental contaminants. Dust and dirt can lead to a range of problems, from mechanical failure to impaired functionality of electronic components. By keeping such contaminants outside, these seals enhance the operational efficiency and lifespan of the equipment.

2. Mitigation of Wear and Tear High levels of dust can cause excessive wear on moving parts. This wear can result in malfunctions and increased maintenance costs. Dust proof seals help minimize this wear by keeping harmful particles at bay, thus ensuring that machinery operates smoothly and remains efficient.

3. Enhancement of Safety In certain applications, dust and debris can create hazardous conditions, particularly in industries such as construction or manufacturing. Dust proof seals help maintain a cleaner and safer working environment by preventing dust accumulation, thus reducing the risk of accidents and exposure to harmful particles.

4. Preservation of Performance For electronic devices, even the smallest amount of dust can disrupt performance. Dust particles can cause overheating, short-circuiting, and reduced efficiency. By using dust proof seals, manufacturers can ensure that electronic devices operate at their optimal performance levels for extended periods.

dust proof seal

Applications of Dust Proof Seals

The versatility of dust proof seals means they can be found in a diverse range of industries

- Consumer Electronics Smartphones, laptops, and other gadgets often employ dust proof seals to protect internal components from dirt, which can compromise functionality.

- Automotive Industry In vehicles, dust proof seals are crucial for engine compartments and electrical systems. They help in maintaining cleanliness and ensuring that operational components remain unaffected by external elements.

- Industrial Machinery In the manufacturing sector, machines are exposed to dust and debris regularly. Dust proof seals are essential in preventing these contaminants from causing breakdowns or inefficiency in operations.

- Aerospace The aerospace industry also heavily relies on dust proof seals to ensure that sensitive instruments and systems operate without interference from particulate matter during flights.

Conclusion

In conclusion, dust proof seals are an essential component in many of today’s technologies and systems. They provide critical protection against contaminants, enhance safety, mitigate wear and tear, and help preserve the efficiency of devices and machinery. As industries continue to advance and evolve, the demand for effective sealing solutions will only grow, making dust proof seals an integral part of modern engineering and design considerations. Investing in high-quality dust proof seals can ultimately lead to greater reliability, lower maintenance costs, and improved overall performance in various applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories