dec . 04, 2024 09:42 Back to list

oil seal manufacturer

Understanding Oil Seal Manufacturers A Comprehensive Overview

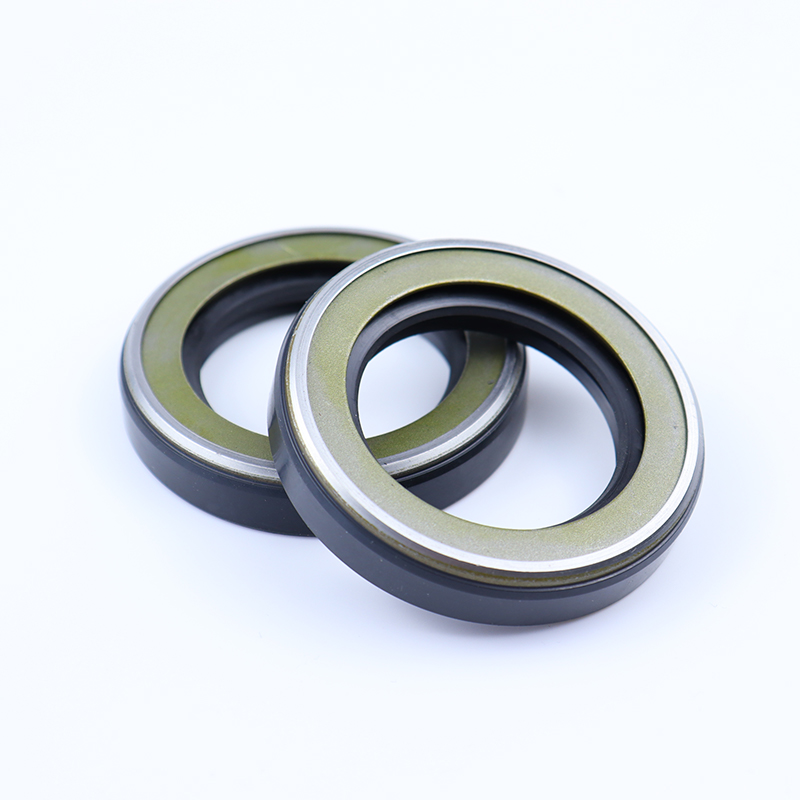

Oil seals, also known as shaft seals or lip seals, play a crucial role in various mechanical systems by preventing leakage of lubricants and blocking contaminants. These components are widely used in automotive, industrial, and aerospace applications, where the integrity of fluid systems is vital for operational efficiency and safety. In this article, we will explore the significance of oil seal manufacturers, their production processes, and the factors to consider when selecting a supplier.

The Role of Oil Seals

Oil seals are designed to retain oil or other lubricants within a machinery component while keeping out dirt, dust, and other particulates. They are typically made from materials such as rubber, silicone, or polyurethane, which offer flexibility, resilience, and resistance to wear and temperature fluctuations. The primary function of an oil seal is to create a reliable seal between rotating and stationary surfaces, thus ensuring that lubricants do not leak and that external contaminants do not penetrate the system.

The performance of oil seals is critical in maintaining the longevity and efficiency of machinery. A malfunctioning seal can lead to lubricant leakage, resulting in increased friction, overheating, and ultimately, premature equipment failure. Therefore, choosing high-quality oil seals from reputable manufacturers is essential for effective maintenance and operation of machinery.

The Manufacturing Process

The process of manufacturing oil seals involves several key steps, including material selection, molding, curing, and quality control

.1. Material Selection The choice of material is fundamental in determining the performance characteristics of oil seals. Manufacturers often use elastomers like nitrile rubber (NBR), fluoroelastomer (FKM), and ethylene propylene diene monomer (EPDM), each offering specific advantages in terms of temperature resistance, oil compatibility, and durability.

2. Molding Once the material is selected, it is subjected to molding processes. The most common method is injection molding, where heated rubber is injected into a mold to form the sealing lip and outer components of the oil seal. This process ensures consistent thickness and precise dimensions.

3. Curing After molding, the seals must undergo curing, a process that involves heating the material to facilitate cross-linking. This step enhances the elasticity and strength of the rubber, making the oil seal more durable and effective in sealing applications.

oil seal manufacturer

4. Quality Control To ensure that every oil seal meets industry standards, manufacturers conduct rigorous quality control checks. These include dimensional inspections, material tests, and performance evaluations to confirm that the seals can withstand specified operating conditions.

Selecting an Oil Seal Manufacturer

When choosing an oil seal manufacturer, several factors should be considered

1. Experience and Reputation Look for manufacturers with a proven track record in the industry. Companies with extensive experience are likely to have refined their processes and developed a robust understanding of customer needs.

2. Quality Certifications Reputable manufacturers often possess quality certifications such as ISO 9001. These credentials indicate adherence to international quality management standards, ensuring that the products are reliable and meet necessary regulations.

3. Customization Options Depending on your specific requirements, it may be beneficial to partner with a manufacturer that offers customization options. Custom seals can be designed to fit unique machinery specifications, enhancing operational efficiency.

4. Technical Support A reliable manufacturer should provide excellent technical support and guidance in selecting the right oil seals for your applications. Their expertise can help in addressing any concerns regarding performance, material compatibility, and installation.

5. Cost-Effectiveness While quality should never be compromised, it's important to evaluate the cost-effectiveness of the products. Comparing quotes from different manufacturers can help you make an informed decision without sacrificing quality.

Conclusion

Oil seal manufacturers are pivotal in ensuring the reliability and functionality of numerous mechanical systems. By understanding the manufacturing process and carefully selecting suppliers, businesses can secure high-quality oil seals that contribute to the longevity and efficiency of their machinery. The importance of choosing the right manufacturer cannot be overstated, as quality seals can prevent costly downtime and maintenance issues. In an ever-evolving market, staying informed about advancements in oil seal technology and manufacturing practices can give businesses a competitive edge.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories