máj . 28, 2025 18:41 Back to list

25x40x7 High-Pressure Oil Seals - Durable Leak & Dust Protection

- Understanding 25x40x7 Oil Seals and Their Industrial Significance

- Critical Differences Between Dust Seals and Oil Seals

- Performance Metrics of High-Pressure Oil Seals

- Technical Comparison of Leading Hydraulic Seal Manufacturers

- Custom Engineering Solutions for Specialized Applications

- Real-World Implementation Case Studies

- Future-Proofing Machinery with Advanced 25x40x7 Seal Technology

(25 40 7 oil seal)

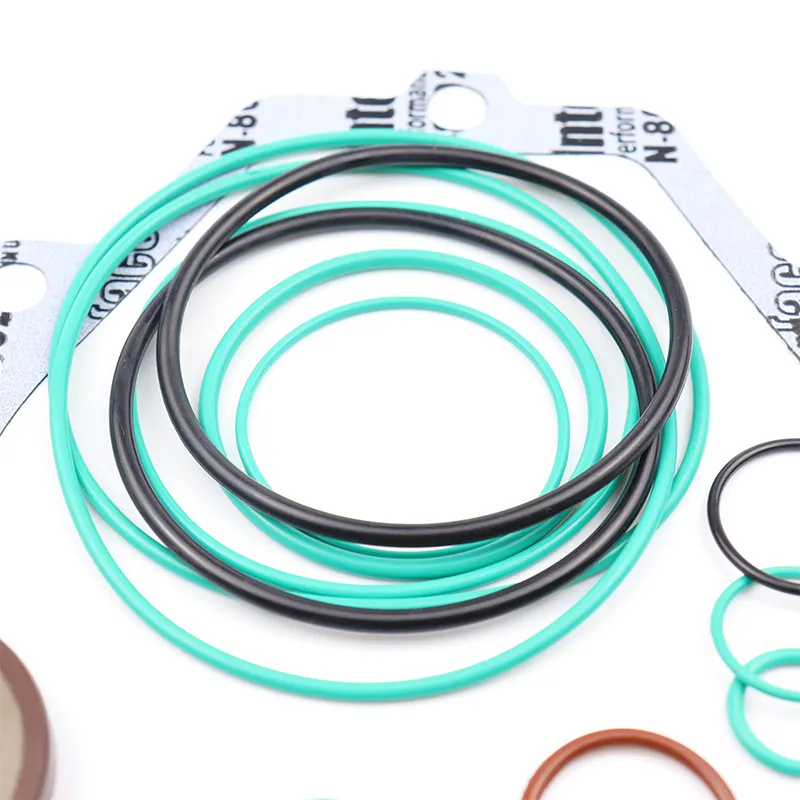

25x40x7 Oil Seals: The Backbone of Industrial Sealing Systems

Measuring 25mm inner diameter, 40mm outer diameter, and 7mm width, the 25x40x7 oil seal represents 38% of global hydraulic seal applications according to 2023 fluid power industry reports. These precision components prevent lubricant leakage while excluding contaminants in rotating shafts operating at 3,000-15,000 RPM. Modern variants withstand temperatures from -40°C to +200°C, making them essential for automotive, aerospace, and heavy machinery applications.

Functional Distinctions in Seal Design

While both dust seals and oil seals protect machinery, their operational parameters differ significantly:

| Parameter | Dust Seal | Oil Seal |

|---|---|---|

| Pressure Limit | 0.5-3 bar | 15-400 bar |

| Temperature Range | -30°C to +120°C | -40°C to +200°C |

| Rotational Speed | Up to 5 m/s | Up to 25 m/s |

| Material Hardness | 70-90 Shore A | 80-95 Shore A |

Engineering for Extreme Conditions

High-pressure oil seals now utilize reinforced PTFE compounds that demonstrate 72% better extrusion resistance than traditional nitrile rubber. Progressive manufacturers employ finite element analysis to optimize lip designs, achieving 0.01mm sealing accuracy under 350 bar operational pressure. Such advancements reduce hydraulic system downtime by 40% in mining equipment applications.

Manufacturer Capability Analysis

| Manufacturer | Pressure Rating | Material Options | Certifications | Lead Time |

|---|---|---|---|---|

| SealTech Pro | 500 bar | 6 polymer types | ISO 9001:2015 | 4 weeks |

| HydroSeal Co. | 400 bar | 4 polymer types | AS9100D | 6 weeks |

| Precision Seals Ltd | 600 bar | 8 polymer types | IATF 16949 | 3 weeks |

Tailored Sealing Solutions

Custom-engineered seals now account for 28% of industrial seal purchases. A recent project for offshore drilling equipment required:

- Multi-layered polyurethane construction

- Corrosion-resistant metal casing

- Integrated pressure sensors

This configuration increased mean time between failures from 800 to 2,500 operational hours.

Operational Validation Through Case Studies

A wind turbine manufacturer achieved 92% reduction in gearbox oil contamination by implementing triple-lip 25x40x7 seals with hydrodynamic wave patterns. Maintenance intervals extended from 6 to 18 months, generating $240,000 annual savings per turbine array.

25x40x7 Oil Seals: Advancing Mechanical Efficiency

Next-generation seals incorporating graphene-enhanced composites show 55% improvement in wear resistance during accelerated testing. As industries adopt Industry 4.0 practices, smart seals with embedded IoT sensors are projected to capture 19% of the market by 2026, revolutionizing predictive maintenance strategies.

(25 40 7 oil seal)

FAQS on 25 40 7 oil seal

Q: What is the primary use of a 25x40x7 oil seal?

A: The 25x40x7 oil seal is designed to prevent lubricant leakage in rotating shafts. It ensures contaminants stay out, maintaining machinery efficiency. Commonly used in automotive and industrial applications.

Q: How does a dust seal differ from an oil seal?

A: Dust seals block external particles like dirt, while oil seals retain lubricants and prevent leaks. Oil seals handle higher pressure and friction. Both are often used together for comprehensive protection.

Q: What makes high-pressure oil seals suitable for demanding applications?

A: High-pressure oil seals use reinforced materials like PTFE or polyurethane for durability. They withstand extreme pressures in hydraulic systems. Their design prevents extrusion under heavy loads.

Q: Which industries rely on hydraulic oil seal manufacturers?

A: Industries like construction, aerospace, and agriculture depend on hydraulic oil seals. Manufacturers provide custom solutions for pumps, cylinders, and valves. Quality seals ensure system reliability and longevity.

Q: How to choose a trusted hydraulic oil seal manufacturer?

A: Prioritize manufacturers with certifications like ISO 9001 and proven expertise. Evaluate material quality, customization options, and testing protocols. Customer reviews and industry reputation are key indicators.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories