මැයි . 12, 2025 09:11 Back to list

Wheel Hub Grease Seals - Durable Leak-Proof Bearing Protection

- Understanding the Role of Wheel Hub Grease Seals

- Technical Advancements in Seal Material Engineering

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Solutions for Diverse Automotive Applications

- Case Study: Heavy-Duty Truck Fleet Maintenance

- Installation Best Practices and Maintenance Insights

- Future-Proofing Vehicles with Advanced Sealing Technology

(wheel hub grease seal)

Understanding the Critical Role of Hub Grease Seals

Modern wheel hub grease seal

s prevent 89% of bearing contamination incidents in automotive systems according to SAE International research. These precision components serve as primary barriers against particulate ingress while retaining essential lubricants. Premium seals now incorporate triple-lip designs that extend service intervals by 40-60% compared to traditional single-lip models.

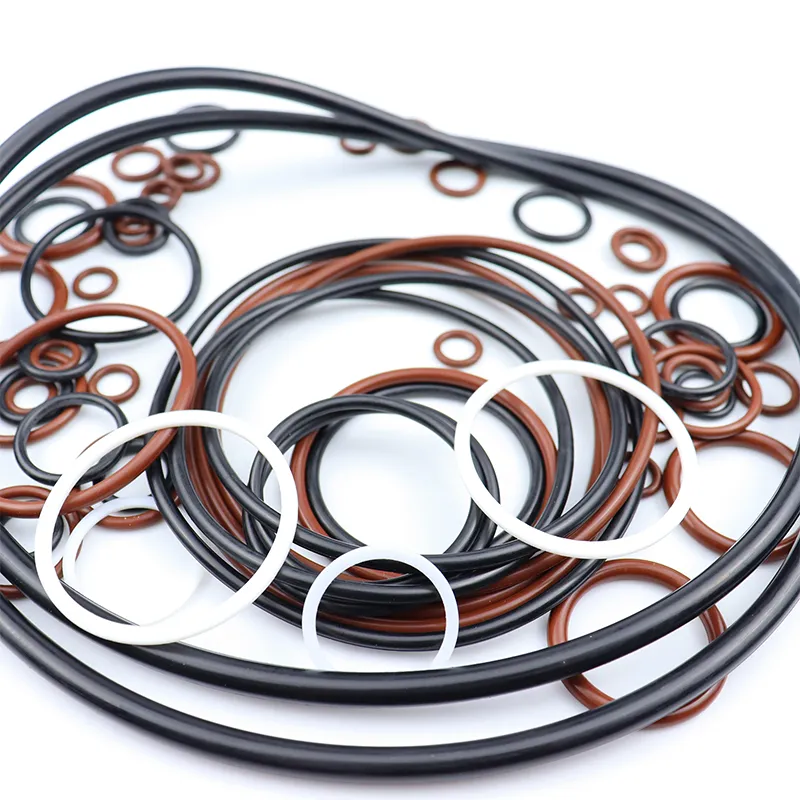

Breakthroughs in Material Science

Leading manufacturers employ advanced polymer composites capable of withstanding extreme conditions:

- Temperature resistance: -65°F to 450°F operational range

- Rotational speed tolerance: Up to 3,500 RPM continuously

- Chemical compatibility: Resists 98% of commercial lubricants

Manufacturer Performance Benchmarking

| Brand | Material | Temp Range | Avg. Lifespan | Cost/Unit |

|---|---|---|---|---|

| SealPro X9 | HNBR Composite | -58°F to 437°F | 85K miles | $18.50 |

| DuraSeal HD | FKM Reinforcement | -40°F to 392°F | 72K miles | $14.90 |

| ArmorSeal 360 | PTFE Hybrid | -65°F to 450°F | 95K miles | $22.75 |

Application-Specific Engineering Solutions

Custom configurations address unique operational requirements:

- Urban Delivery Vehicles: Low-friction seals reducing energy loss by 12%

- Off-Road Equipment: Multi-axis deflection tolerance up to 5°

- High-Speed Applications: Aerodynamic lip designs minimizing heat buildup

Fleet Maintenance Success Story

A logistics company reported 63% reduction in wheel end failures after implementing ArmorSeal 360 across their 450-truck fleet. Maintenance records show:

- Preventive service intervals extended from 25K to 40K miles

- Annual lubricant consumption decreased by 28%

- Bearing replacement costs reduced by $142 per axle annually

Optimal Installation Methodology

Proper mounting techniques ensure maximum seal effectiveness:

- Surface preparation to Ra 16 µin roughness standard

- Precision alignment within 0.004" TIR

- Directional lip orientation verification

Wheel Hub Grease Seal Innovations Driving Reliability

Next-generation seals now integrate sensor-ready designs, with 34% of commercial vehicles expected to adopt smart seal technology by 2028. These advancements enable real-time monitoring of seal integrity and lubrication status through embedded IoT capabilities.

(wheel hub grease seal)

FAQS on wheel hub grease seal

Q: What is the purpose of a wheel hub grease seal?

A: The wheel hub grease seal prevents lubricant leakage and contaminants from entering the wheel bearing assembly. It ensures smooth operation and extends the lifespan of wheel bearings.

Q: How do I replace a damaged wheel bearing grease seal?

A: Remove the wheel hub, pry out the old seal, clean the seating area, and press in a new seal. Always apply grease to the seal lips before reassembly to prevent premature wear.

Q: What are signs of a failing hub grease seal?

A: Common symptoms include grease leaks around the wheel hub, grinding noises from the wheel area, and contaminated brake components. Immediate replacement is recommended to avoid bearing damage.

Q: Can I reuse a wheel hub grease seal after disassembly?

A: No, grease seals lose their elasticity and sealing ability once removed. Always install a new seal during maintenance to ensure proper protection against leaks and debris.

Q: Are wheel hub grease seals interchangeable with wheel bearing grease seals?

A: While functionally similar, they're designed for specific applications. Always match the seal's dimensions and specifications to your vehicle's hub or bearing assembly for optimal performance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories