දෙසැ. . 11, 2024 10:58 Back to list

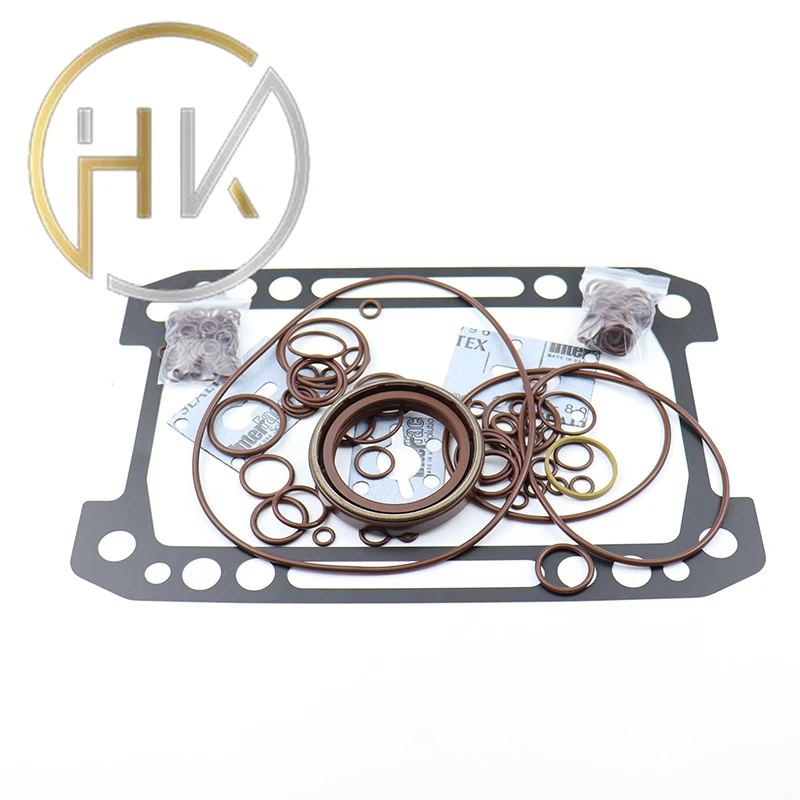

Hydraulic Seal Maintenance and Repair Toolkit for Effective Equipment Performance and Longevity

Understanding Hydraulic Seal Repair Kits

Hydraulic systems are critical components in various machinery and equipment, providing the necessary force and movement for numerous applications. Whether in construction equipment, automotive systems, or industrial machinery, hydraulic systems must function reliably to ensure operational efficiency. However, like any mechanical system, hydraulic components can fail over time due to wear and tear, contamination, or improper maintenance. One common issue is the deterioration of hydraulic seals, which can lead to fluid leaks and reduced system performance. This is where hydraulic seal repair kits come into play.

What is a Hydraulic Seal Repair Kit?

A hydraulic seal repair kit is a collection of components specifically designed to restore the integrity and functionality of hydraulic seals. Typically, these kits include various types of seals, O-rings, backup rings, and other essential hardware that may be necessary for the repair process. The kits are tailored for different hydraulic applications, ensuring compatibility with specific machinery and equipment. By providing the necessary tools and replacements, these kits enable users to perform repair tasks efficiently and effectively.

Importance of Hydraulic Seal Repair Kits

1. Cost-Effectiveness Replacing an entire hydraulic component or system can be prohibitively expensive. Hydraulic seal repair kits offer a cost-effective solution by allowing users to replace only the failed seals, thus extending the life of the existing components. This can result in significant savings, particularly for businesses that rely heavily on hydraulic systems.

2. Minimizing Downtime Equipment failure can lead to downtime, which is costly for any operation. Having a hydraulic seal repair kit on hand enables quick repairs, minimizing the time machinery spends out of service. This agility is crucial, especially in industries where productivity is paramount.

3. DIY Maintenance Many hydraulic seal repair kits are designed for easy use by individuals with basic mechanical skills. This empowers operators to perform their maintenance and repairs, reducing reliance on specialized service technicians and allowing for a quicker response to issues.

4. Improved Performance and Reliability Regular maintenance and timely seal replacement can significantly enhance the performance of hydraulic systems. Using a repair kit to replace worn or damaged seals helps prevent leaks, ensuring optimal fluid pressure and performance levels.

hydraulic seal repair kit

Choosing the Right Hydraulic Seal Repair Kit

Selecting the appropriate hydraulic seal repair kit is crucial to achieving successful repairs. Here are some factors to consider

- Compatibility Ensure the kit is compatible with the specific hydraulic equipment you are working on. Seals come in various sizes and materials, and using the wrong type can lead to further issues.

- Quality of Components Look for kits that offer high-quality seals and O-rings made from durable materials, such as nitrile rubber or polyurethane. High-quality components are essential for ensuring longevity and effectiveness.

- Comprehensive Selection A good repair kit should provide a variety of seals and components to cover different issues that may arise. Kits that include a range of sizes and types can be more versatile and useful for future repairs.

- Instructions and Support Some kits come with detailed instructions on how to perform the repairs. Support from the manufacturer or supplier for troubleshooting can also be invaluable, especially for those new to hydraulic repairs.

Conclusion

Hydraulic seal repair kits play a vital role in maintaining the performance and reliability of hydraulic systems in various applications. By understanding the benefits of these kits and selecting the right one for your needs, you can save time and money while ensuring your hydraulic equipment operates efficiently. Whether you are a DIY enthusiast or a professional mechanic, having a hydraulic seal repair kit in your toolkit can be an invaluable asset, helping to keep your machinery running smoothly and effectively. Regular maintenance and prompt repairs using these kits can ultimately lead to improved productivity and reduced operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories