නොවැ. . 08, 2024 23:09 Back to list

Hydraulic Cylinder Seal Kit for Efficient Repair and Maintenance Solutions

Understanding Hydraulic Cylinder Repair Seal Kits

Hydraulic systems are the backbone of many industrial and commercial applications, serving critical functions in machinery and equipment ranging from construction vehicles to manufacturing processes. At the heart of these systems is the hydraulic cylinder, which converts hydraulic energy into mechanical force. However, like all mechanical components, hydraulic cylinders can encounter issues that necessitate maintenance and repair. One of the most common repair tasks involves replacing seals to ensure optimal functionality and prevent leaks. This is where hydraulic cylinder repair seal kits come into play.

What is a Hydraulic Cylinder Seal Kit?

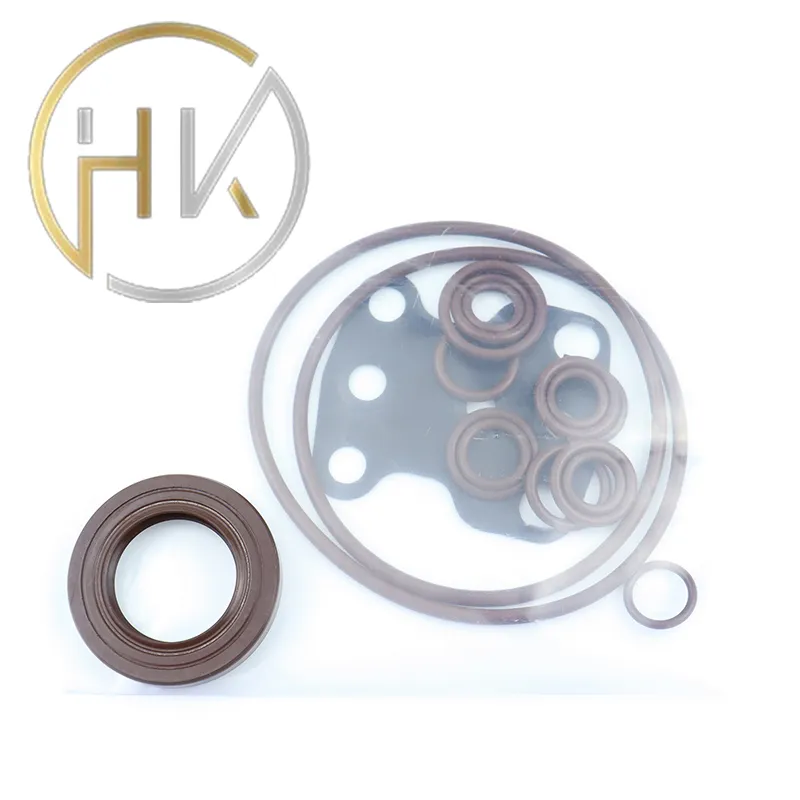

A hydraulic cylinder repair seal kit comprises a collection of seals, O-rings, and other related components designed specifically for the maintenance and repair of hydraulic cylinders. These kits typically include various seal types, such as piston seals, rod seals, and backup rings, each tailored to specific applications and cylinder designs. By using a repair seal kit, technicians can restore a hydraulic cylinder's performance without the need for complete replacement, saving both time and money.

Why Seals Matter

The seals within a hydraulic cylinder play a crucial role in maintaining operational efficiency. They prevent hydraulic fluid from leaking out of the cylinder, ensuring that the system can generate the necessary pressure and force. Over time, seals can deteriorate due to friction, heat, exposure to chemicals, and other environmental factors. When seals fail, it can lead to decreased efficiency, increased wear on components, and potentially catastrophic system failures. Therefore, regular inspection and timely replacement of seals are essential to prolonging the life of hydraulic cylinders and maintaining equipment performance.

Components of a Hydraulic Cylinder Repair Seal Kit

1. Piston Seals These seals fit inside the cylinder and prevent fluid from leaking past the piston during operation. They need to withstand high pressure and offer low friction for smooth operation.

2. Rod Seals Located at the rod end of the cylinder, these seals are designed to prevent fluid from leaking out while also keeping contaminants out. They are critical for protecting the internal components of the cylinder.

3. O-Rings These versatile seals are used in various applications within the hydraulic system. They create a tight seal between components, ensuring that hydraulic fluid remains contained.

hydraulic cylinder repair seal kit

4. Backup Rings Often used in conjunction with O-rings, backup rings provide additional support and help to prevent extrusion of the O-ring under high pressure.

5. Dust Seals These seals prevent dirt and contaminants from entering the cylinder, which could cause wear and damage. They are particularly important in harsh working environments.

Choosing the Right Seal Kit

Selecting the appropriate hydraulic cylinder repair seal kit is crucial for successful repairs. Factors to consider include

- Compatibility Ensure that the seals are compatible with the specific hydraulic cylinder model and its application. Different cylinders may require unique seals based on size, pressure rating, and material compatibility.

- Material Quality Seals can be made from various materials, including nitrile, polyurethane, and fluorocarbon. The material should be selected based on the operating temperature, pressure, and fluid compatibility.

- Kit Completeness A comprehensive seal kit should include all necessary components for a complete repair. Before purchasing, verify that the kit has all the items required for your specific application.

Conclusion

Hydraulic cylinder repair seal kits are essential for maintaining the efficiency and longevity of hydraulic systems. By regularly inspecting and replacing seals, operators can prevent leaks, reduce downtime, and avoid costly repairs. Understanding the components and choosing the right seal kit can empower technicians to keep hydraulic cylinders running smoothly, ultimately contributing to safer and more efficient operations in various industries. Investing in quality seal kits is not only a practical approach to maintenance but also a step towards ensuring the reliability of vital hydraulic equipment.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories