නොවැ. . 04, 2024 22:31 Back to list

high pressure rotary shaft seal

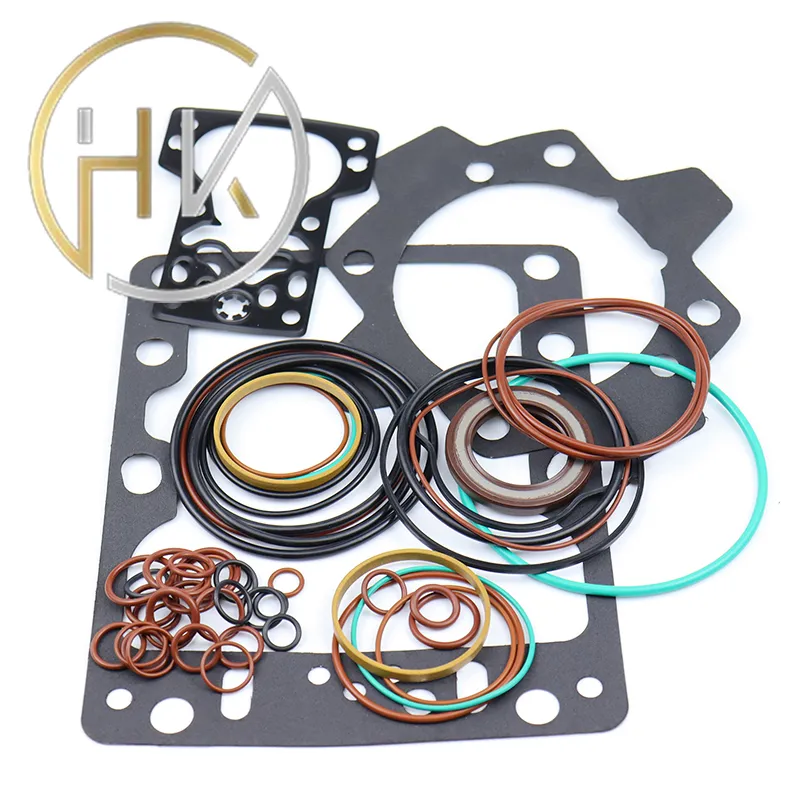

Understanding High Pressure Rotary Shaft Seals

Rotary shaft seals play a crucial role in various mechanical systems by preventing the leakage of fluids while allowing the shaft to rotate. These seals are essential components in many applications, particularly in industries that handle high-pressure systems. This article aims to provide a comprehensive overview of high-pressure rotary shaft seals, their construction, working principles, applications, and maintenance considerations.

Construction of High-Pressure Rotary Shaft Seals

High-pressure rotary shaft seals typically consist of several key components the seal body, sealing lip, spring mechanism, and auxiliary components like O-rings or backup rings. The seal body is made from durable materials such as elastomers, PTFE (Polytetrafluoroethylene), or specialty polymers, designed to withstand high pressure and temperature variations. The sealing lip, which makes direct contact with the rotating shaft, is engineered to create a tight seal, preventing the escape of fluids.

The spring mechanism plays a crucial role in maintaining constant pressure against the shaft. It ensures that the sealing lip remains in contact with the shaft, compensating for any wear or distortion that may occur over time. Proper tension is critical; too much pressure can cause excessive wear, while too little can lead to leaks. Additionally, auxiliary components enhance the seal's performance, providing backup support and improving overall reliability.

Working Principle of High-Pressure Rotary Shaft Seals

The fundamental working principle of high-pressure rotary shaft seals involves creating a barrier between the rotating shaft and the surrounding environment. When the shaft rotates, the sealing lip grips the surface of the shaft due to the spring's pressure, creating a hydrodynamic seal. This action generates a film of fluid between the seal and the shaft surface, which helps to reduce friction and prevent wear.

The efficiency of the seal heavily depends on its design and the materials used. High-pressure applications often involve harsh fluids, which requires seals to have excellent chemical resistance and thermal stability. Seals are tested under specific conditions to ensure they can endure the intended operating environment without failing.

Applications of High-Pressure Rotary Shaft Seals

high pressure rotary shaft seal

High-pressure rotary shaft seals are employed in a wide range of industries, including automotive, aerospace, oil and gas, and manufacturing. In the automotive industry, these seals are used in engine components, transmission systems, and pumps. They prevent oil leaks, which can lead to catastrophic engine failures if not managed properly.

In the aerospace sector, rotary shaft seals are vital for aircraft systems that operate under extreme pressure and temperature conditions. They ensure that hydraulic systems function efficiently and without leaks, which is critical for safety and performance.

The oil and gas industry relies heavily on high-pressure rotary shaft seals to maintain the integrity of drilling and extraction equipment. These seals must perform reliably in extreme environments to prevent fluid loss and protect both equipment and the environment.

Maintenance and Considerations

The longevity and performance of high-pressure rotary shaft seals can be significantly impacted by proper maintenance. Regular inspections are essential to detect any signs of wear or damage. Proper installation is also critical; misalignment or incorrect mounting can lead to premature failure.

In high-pressure applications, operating conditions can change, so it’s essential to select the right seal material and design for the specific fluid being contained. Compatibility with the operating fluid, temperature extremes, and pressure levels will dictate the seal's performance lifespan.

It's also worth noting that preventive measures, such as the use of filtration systems to remove contaminants and lubricants designed to enhance seal life, can mitigate wear and prolong the seal's integrity.

Conclusion

High-pressure rotary shaft seals are a vital component in many industrial applications, providing essential functionality by preventing fluid leakage while allowing rotational movement. Their design and material considerations are paramount in ensuring reliability and durability under harsh operating conditions. As technologies evolve, advancements in seal materials and designs will enhance their performance, contributing to greater efficiency and safety across various industries. By understanding their construction, working principles, applications, and maintenance needs, professionals can make informed decisions that lead to better performance and longevity in their systems.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories