Dec . 17, 2024 01:49 Back to list

seal hydraulic pump

Understanding Seal Hydraulic Pumps A Comprehensive Overview

Seal hydraulic pumps are essential components in various industrial applications, machinery, and systems that rely on hydraulic power. These pumps play a crucial role in converting mechanical energy into hydraulic energy, enabling the efficient transfer of power through hydraulic fluid. In this article, we will delve into the workings of seal hydraulic pumps, their types, functionalities, advantages, and applications.

What is a Seal Hydraulic Pump?

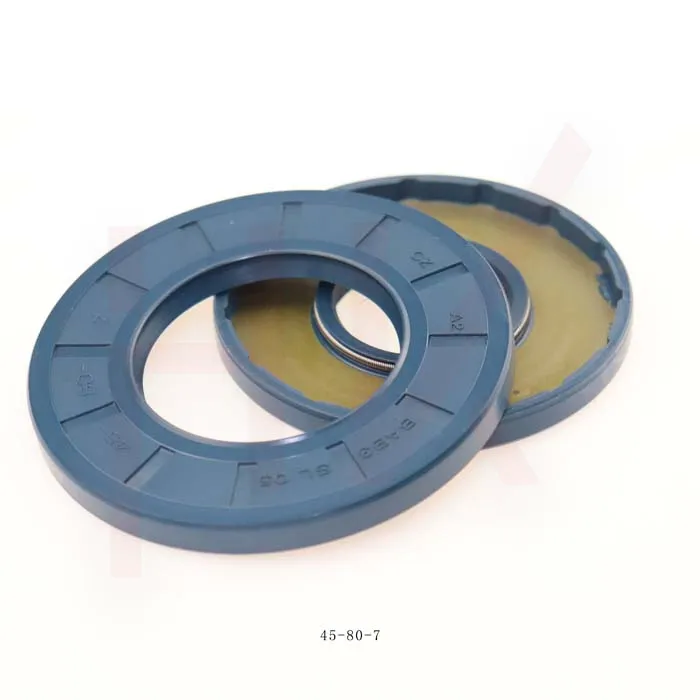

A seal hydraulic pump is a type of hydraulic pump that utilizes seals to maintain pressure and prevent fluid leakage. These pumps are designed to handle high pressures and deliver precise control over fluid movement. The seals used in these pumps are critical, as they help ensure stability and reliability during operation. The hydraulic fluid, typically oil, provides lubrication and cooling, which are vital for the pump's longevity and efficiency.

Types of Seal Hydraulic Pumps

There are various types of hydraulic pumps, each tailored to specific applications and operational needs. The most common types include

1. Gear Pumps These pumps use gears to draw in fluid and pump it out. They are known for their simplicity, durability, and ability to handle a wide range of viscosities.

2. Vane Pumps Utilizing rotating vanes, this type of pump provides a smooth and consistent flow. Vane pumps are well-suited for medium-pressure applications and are often used in automotive and industrial equipment.

3. Piston Pumps These pumps use pistons to convert mechanical energy into hydraulic energy. They can generate high pressures and are commonly used in heavy machinery and mobile equipment.

4. Gear-type Pumps These pumps use positive displacement mechanisms and are ideal for applications requiring precise flow rates. They can operate efficiently at varying speeds and pressures.

How Seal Hydraulic Pumps Work

The operation of a seal hydraulic pump involves several components, including the pump casing, seals, rotor, and drive mechanism. When the pump is activated, the drive mechanism initiates the rotation of the rotor. This rotation creates a vacuum within the pump casing, causing hydraulic fluid to be drawn into the pumping chamber.

As the rotor continues to turn, the fluid is trapped between the rotor and the casing. The design of the pump and the movement of the rotor generates pressure, pushing the fluid out through the outlet port. The seals ensure that the fluid does not escape during this process, maintaining the pressure required for effective hydraulic operation.

Advantages of Seal Hydraulic Pumps

seal hydraulic pump

Seal hydraulic pumps offer numerous advantages that make them popular in various industries

1. Efficiency These pumps are designed for efficient fluid transfer, minimizing energy loss during operation. This efficiency translates into lower operational costs.

2. Reliability With proper maintenance, seal hydraulic pumps can achieve a long service life. The seals prevent leaks and controlled unwanted wear, ensuring consistent performance.

3. Precision Control Seal hydraulic pumps provide accurate control of fluid flow rates and pressures, which is essential for applications that require precise movements, such as robotics and automated systems.

4. Versatility Seal hydraulic pumps are adaptable to different applications across numerous industries, including construction, manufacturing, automotive, and agriculture.

Applications of Seal Hydraulic Pumps

Seal hydraulic pumps are employed in various applications, including

- Construction Equipment Used in excavators, bulldozers, and lifts, hydraulic pumps facilitate the movement and operation of heavy machinery.

- Industrial Systems Hydraulic pumps power conveyor systems, material handling equipment, and robotic arms, enhancing productivity in manufacturing.

- Automotive Applications They are essential in hydraulic brakes, power steering systems, and automatic transmissions.

- Aerospace and Defense In aircraft, hydraulic pumps control various systems such as landing gear, flight control surfaces, and weapon systems.

Conclusion

In summary, seal hydraulic pumps are indispensable in modern engineering and industrial processes. Their ability to efficiently convert mechanical energy into hydraulic power allows for vast applications across various sectors. By understanding the design, operation, and benefits of seal hydraulic pumps, industries can optimize their use, leading to improved productivity and reliability. As technology advances, we can expect even more innovations in hydraulic pump design, paving the way for enhanced performance in the future.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories