Dec . 05, 2024 10:01 Back to list

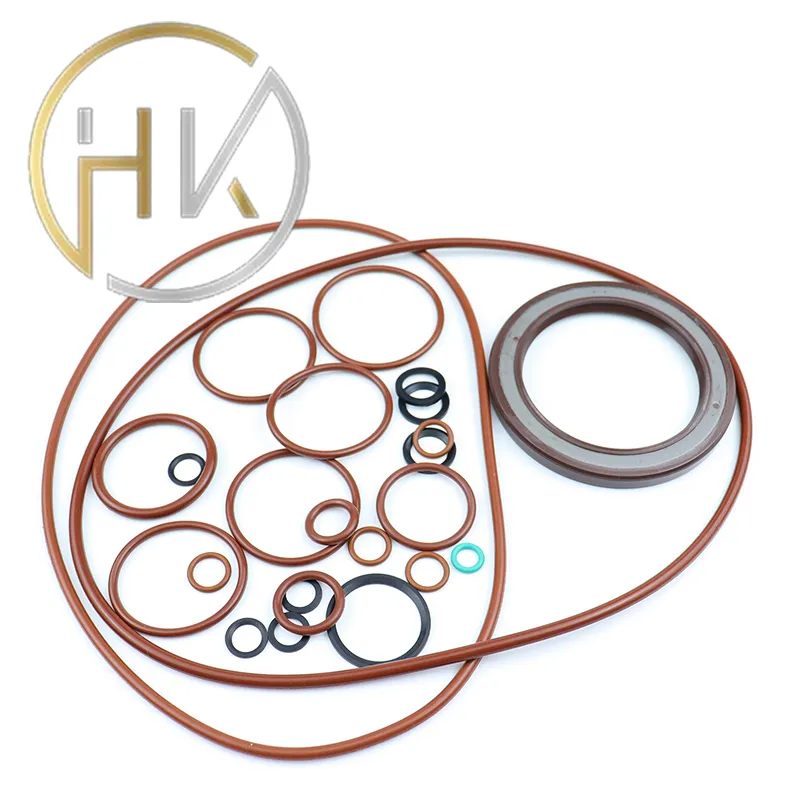

High Performance O-Ring Kit for Extreme Temperature Applications

Understanding High Temperature O-Ring Kits An Essential Tool for Various Applications

O-rings are ubiquitous components employed in many industries, serving as essential seals that prevent the escape of fluids and gases. When dealing with high temperature environments, the choice of materials and the design of these O-rings become crucial. High temperature O-ring kits are specifically formulated to offer durability and resilience under extreme conditions. In this article, we will explore the significance, applications, materials, and benefits of high temperature O-ring kits.

The Importance of High Temperature O-Rings

Every industry, from aerospace to automotive, relies on the ability to maintain pressure and contain substances. High temperature O-rings are designed to operate effectively in environments that exceed the standard limits set for regular O-rings. Such conditions may occur in applications involving engines, turbines, and chemical processing plants, where temperatures can rise significantly, and failure to perform might result in severe consequences, including system failures or safety hazards.

Applications Across Industries

High temperature O-rings find use in various sectors. Some common applications include

1. Aerospace In aerospace applications, components must withstand extreme temperatures and pressure variations. High temperature O-rings are critical in engines, fuel systems, and hydraulic systems, ensuring reliability in critical operations. 2. Automotive In the automotive industry, O-rings are used to create tight seals in systems like oil pumps, transmissions, and cooling systems. High temperature O-rings are essential for performance and safety, especially in high-performance engines.

3. Chemical Processing Chemical plants often operate under high temperatures and corrosive conditions. High temperature O-rings made from resistant materials ensure long-lasting seals, preventing leaks and contamination.

4. Industrial Machinery Many machines operate under significant heat generated by friction and activity. High temperature O-rings help reduce wear and prolong equipment life by providing excellent sealing capabilities at elevated temperatures.

Materials Selection

The effectiveness of high temperature O-rings is largely attributed to the materials used to produce them. Common materials include

high temperature o ring kit

2. Silicone Known for its flexibility and thermal stability, silicone O-rings can withstand a range of temperatures, making them ideal for applications in both high heat and low-temperature environments.

3. Polyacrylate This synthetic rubber can handle higher temperatures than standard O-ring materials, making it suitable for several demanding applications.

4. PTFE (Polytetrafluoroethylene) PTFE is highly resistant to high temperatures and chemicals, providing excellent durability and longevity in severe conditions.

When selecting materials for high temperature O-rings, it is crucial to consider not only the temperature range but also exposure to chemicals and other environmental factors.

Benefits of Using High Temperature O-Ring Kits

1. Reliability High temperature O-rings are engineered to provide consistent performance, minimizing the risk of leaks and mechanical failures.

2. Longevity These seals resist wear and degradation, extending the lifespan of the components they serve, which leads to reduced maintenance and replacement costs.

3. Versatility High temperature O-ring kits come in various sizes and materials, making them suitable for diverse applications across different industries.

4. Safety By ensuring tight seals under extreme conditions, high temperature O-rings contribute to operational safety, preventing potentially dangerous leaks or ruptures.

Conclusion

High temperature O-ring kits are indispensable in environments where precision sealing is paramount. Their durability, versatile applications, and ability to withstand extreme conditions make them a preferred choice in many industries. Understanding the materials and types available is essential for engineers and maintenance professionals to ensure optimal selection for their specific applications. By equipping systems with the proper O-rings, businesses can improve efficiency and safety while minimizing downtime and repair costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories