Dec . 22, 2024 17:55 Back to list

Alternative Oil Seal Specifications 25% 40% 7% Insights and Comparisons

Understanding the Importance of Oil Seals A Closer Look at 25%, 40%, and 7% Specifications

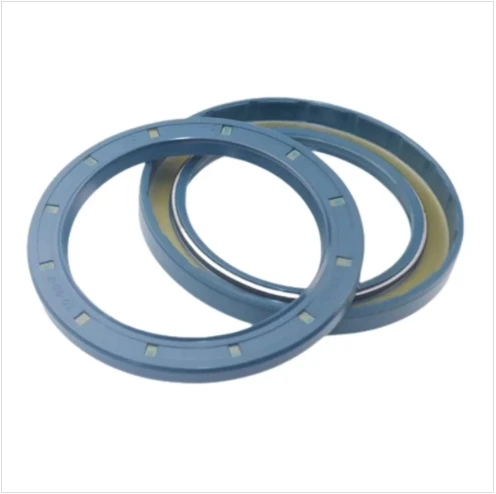

Oil seals are essential components in various machinery and mechanical systems, designed to prevent the leakage of oils and fluids, ensuring that these systems operate efficiently and effectively. Understanding the specifications of oil seals, such as the references to 25%, 40%, and 7%, can help in selecting the right oil seal for a specific application. This article aims to delve into the significance of these figures, their implications on oil seal performance, and the overall impact on machinery longevity.

The Role of Oil Seals in Machinery

Before exploring the specifications, it’s important to understand the fundamental role of oil seals. Oil seals are used to encapsulate lubricants within machinery, preventing contaminants such as dirt, water, and dust from entering the lubricant. They are vital in maintaining the integrity and performance of mechanical systems, as leaks can lead to serious operational issues, increased wear, or even catastrophic failures.

Decoding the Numbers 25%, 40%, and 7%

When discussing oil seals, the percentages often relate to various performance aspects, including tolerance, elasticity, and material composition. Let's explore what each of these percentages may represent

1. 25% - Tolerance Levels The percentage might indicate a specific tolerance level for the oil seal, determining how much deviation from the ideal shape or size is acceptable for effective sealing. A 25% tolerance means that the seal can slightly deviate without compromising its function. High tolerance levels are particularly critical in high-speed applications where precision is paramount. Properly toleranced seals contribute to reduced friction and wear, leading to improved efficiency in machinery operation.

2. 40% - Material Performance The 40% specification could relate to the performance characteristics of the seal material, including its ability to withstand pressures and temperatures. For instance, certain materials may retain their sealing properties at elevated temperatures or under high-pressure conditions. Choosing a seal designed to perform up to 40% higher than the operational requirements can provide an extra safety margin, extending the life of the machinery and reducing maintenance costs.

25 40 7 oil seal

3. 7% - Elasticity and Compression Set A 7% rating might refer to the elasticity of the oil seal, indicating how well the material can return to its original shape after being compressed. Elastic materials are crucial in providing a tight seal despite changes in pressure or temperature. This percentage can also point to the compression set of the seal, defining the degree to which a seal retains its original shape after being subjected to prolonged compressive forces. A lower compression set percentage means better performance and longevity of the seal.

Selecting the Right Oil Seal

When selecting an oil seal for an application, consider the environment in which it will operate. Factors such as temperature fluctuations, exposure to chemicals, and the type of machinery can significantly impact the choice of seal.

1. Material Selection Understanding the specific performance characteristics indicated by the percentages can help in selecting a suitable material. For example, synthetic rubber seals may have advantages in high-temperature applications versus traditional rubber.

2. Application Requirements Evaluating the operating conditions and the machinery's specifications is crucial. Higher pressures may necessitate seals with a more robust design, while less demanding applications might afford more flexibility in seal selection.

3. Cost vs. Performance While high-performing seals may be more expensive initially, the return on investment through reduced maintenance and longer service life often outweighs the initial costs.

Conclusion

In conclusion, understanding the significance of specifications like 25%, 40%, and 7% in relation to oil seals can dramatically affect the choice and application of these essential components in machinery. By selecting the right oil seal based on tolerance levels, material performance, and elasticity, businesses can ensure enhanced durability, efficiency, and functionality in their mechanical systems. With the correct oil seal, the longevity of machinery can be optimized, ultimately leading to better operational performance and greater safety in industrial applications. Proper maintenance and understanding of seals are not just good practices but pivotal in sustaining the health of complex machinery ecosystems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories