Dec . 12, 2024 22:45 Back to list

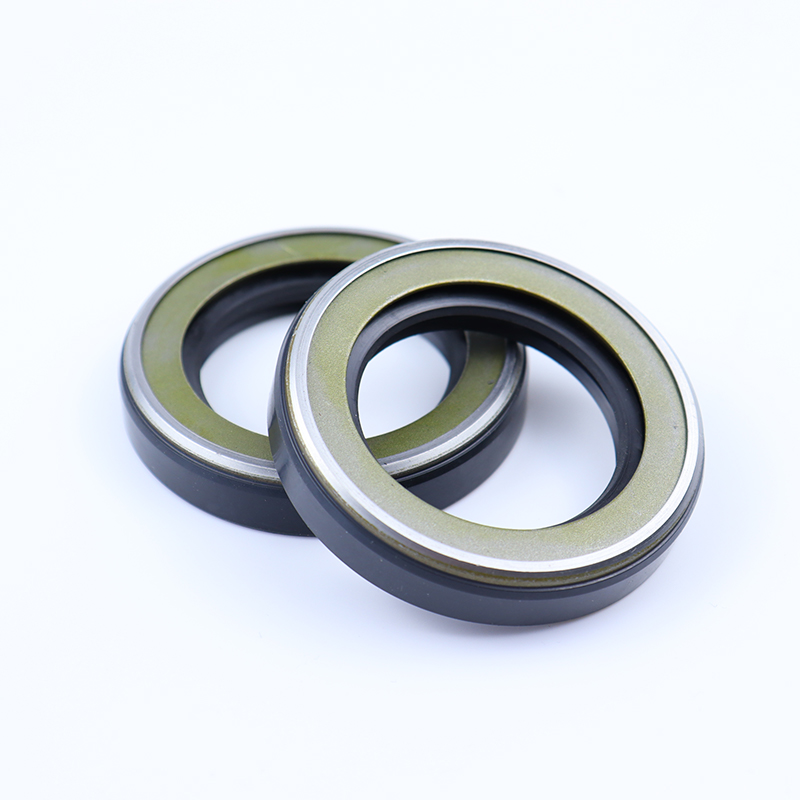

20 30 7 oil seal

Understanding the Importance of Oil Seals A Focus on 20%, 30%, and 7% Specifications

Oil seals, also known as rotary shaft seals, play a crucial role in various mechanical systems by preventing the leakage of substances such as oil and grease. Their significance cannot be understated, as improper sealing can lead to equipment failure, increased maintenance costs, and reduced efficiency. In this article, we will explore the importance of oil seals while focusing on specific parameters 20%, 30%, and 7%, which represent the typical specifications or performance metrics associated with these essential components.

What Are Oil Seals?

Oil seals are circular devices designed to fit snugly around a rotating shaft. They are made from durable materials such as rubber or elastomers and serve as barriers to keep lubricants in and contaminants out. Depending on their design and application, oil seals can resist high temperatures, aggressive chemicals, and varying pressure conditions.

The Importance of Specification

When discussing oil seals, the numbers 20%, 30%, and 7% often refer to different performance metrics, such as the percentage of sealing efficiency, temperature resistance, and deformation limits. Understanding these specifications is vital for selecting the right oil seal for a specific application.

20 30 7 oil seal

1. 20% Sealing Efficiency The 20% specification often refers to a specific leakage allowance that one can tolerate in certain low-pressure applications. While one would generally prefer a sealing efficiency closer to 100%, in some scenarios, a 20% leakage is manageable, particularly when lubrication is abundant and does not pose a significant threat to surrounding components. For example, in agricultural machinery where excessive dust and dirt can compromise the environment, a seal that offers 20% leakage may be acceptable if it is complemented by adequate protection measures.

2. 30% Temperature Resistance The 30% specification refers to the maximum temperature tolerance of the oil seal material. High-temperature environments can cause seals to degrade quickly; thus, knowing a seal's temperature limits is essential. A seal with a 30% tolerance can maintain its integrity and functionality at elevated temperatures, making it suitable for automotive applications where engines often exceed normal operating conditions. When selecting oil seals for high-performance engines, it is imperative to choose a material that can withstand high thermal expansion and contraction without failing.

3. 7% Deformation Limit The 7% specification often pertains to the deformation limit of the oil seal material under pressure and temperature variances. This means that the seal can only deform up to 7% of its original shape before compromising its sealing capabilities. Ensuring that your oil seal can maintain its functionality under stress is crucial. In industrial applications, for instance, if an oil seal deforms beyond its limit, it can lead to oil leaks and costly downtime.

Conclusion

In the realm of mechanical engineering and maintenance, oil seals are indispensable components that ensure the efficient operation of machinery. Understanding their specifications—such as 20% sealing efficiency, 30% temperature resistance, and 7% deformation limit—enables engineers and maintenance professionals to make informed decisions when selecting the right oil seals for their applications. Properly chosen and maintained oil seals can significantly extend the life of equipment, enhance performance, and reduce operational costs, ultimately contributing to a more efficient and reliable mechanical system. As technology continues to advance, new materials and designs will undoubtedly improve oil seal performance, paving the way for safer and more sustainable engineering solutions.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories