Дек . 15, 2024 16:47 Back to list

seal kit for pallet jack

Understanding the Importance of Seal Kits for Pallet Jacks

Pallet jacks are indispensable tools in warehouses, factories, and retail environments. They streamline the process of moving goods, making the handling of heavy loads safer and more efficient. However, like any piece of machinery, they require regular maintenance to ensure optimal performance. One critical component of this maintenance is the seal kit. This article will delve into what seal kits are, their importance, and how to choose the right one for your pallet jack.

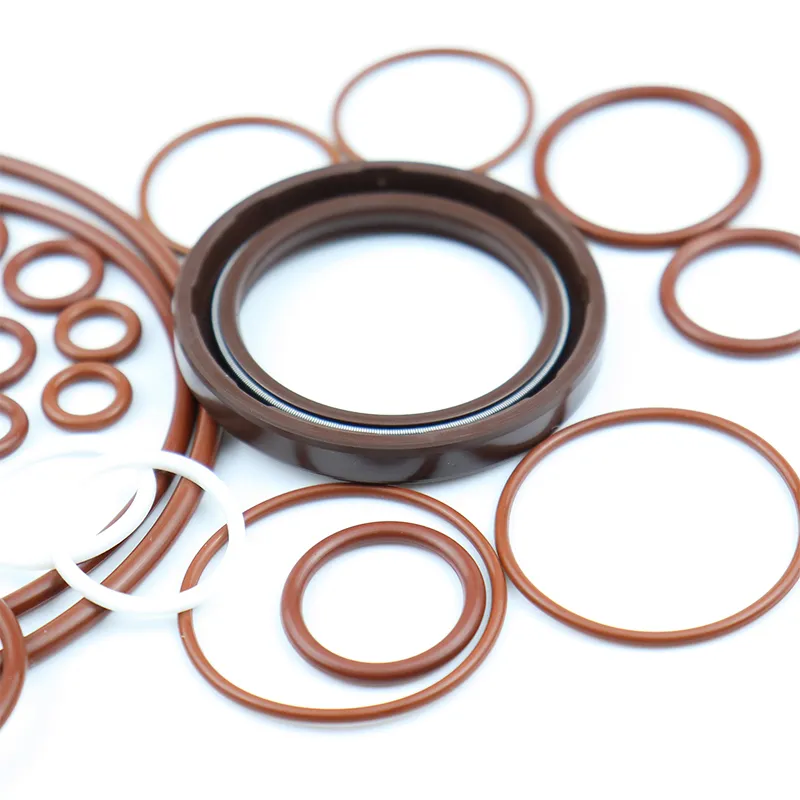

What is a Seal Kit?

A seal kit is a collection of seals and O-rings that are essential for the hydraulic system of your pallet jack. These seals prevent hydraulic fluid from leaking and ensure that the mechanism operates smoothly. When the seals are compromised, it can lead to decreased lifting capacity, reduced control, and even complete failure of the pallet jack.

Importance of Seal Kits

1. Preventing Leaks The primary function of seal kits is to contain hydraulic fluid within the system. If a seal or O-ring wears out, it can lead to leaks, which can compromise the jack’s lifting capabilities and create a hazardous working environment.

2. Maintaining Performance Regularly replacing worn-out seals enhances the performance of your pallet jack. Fresh seals ensure that the hydraulic fluid remains in the system, enabling smooth and reliable operation.

3. Extending Equipment Life By maintaining the integrity of the hydraulic system with quality seal kits, you can extend the life of your pallet jack. Proactive maintenance can save businesses significant amounts in repair costs and downtime.

4. Safety Compliance In many industries, safety is paramount. A malfunctioning pallet jack due to leaking hydraulic fluid can pose risks not only to operators but also to other employees in the area. Using seal kits to keep equipment in good working condition is a critical part of maintaining workplace safety compliance.

Choosing the Right Seal Kit

Selecting the appropriate seal kit for your pallet jack involves several considerations

seal kit for pallet jack

1. Compatibility Ensure that the seal kit is specifically designed for your pallet jack model. Different manufacturers may use various seal configurations, sizes, and materials. Consult your jack's manual or the manufacturer’s website for specifications.

2. Material The material of the seals is crucial for performance and durability. Common materials include nitrile rubber, polyurethane, and silicone. Each material has its advantages and is suitable for different operating conditions. For instance, nitrile rubber is extremely durable and resistant to wear, making it ideal for heavy-duty applications.

3. Quality Assurance Invest in high-quality seal kits from reputable manufacturers. Low-quality seals may save money upfront but can lead to more frequent breakdowns and higher long-term costs in repairs and replacements.

4. Understanding the Application Consider the specific applications and conditions in which the pallet jack operates. For example, if it operates in extreme temperatures or around certain chemicals, choose seals that can withstand those conditions.

Maintenance Tips

To maximize the lifespan of your seal kit and pallet jack

- Regular Inspections Conduct regular inspections of your pallet jack. Look for signs of hydraulic fluid leaks, wear, or damage to the seals.

- Proper Usage Train operators on the correct usage of the pallet jack. Incorrect handling can place unnecessary stress on the machinery, leading to premature wear of seals.

- Timely Replacements If you notice leaks or reduced functionality, replace the seal kit immediately. Delaying maintenance can result in more severe damage to the hydraulic system.

Conclusion

Seal kits are essential components that play a vital role in the operational integrity of pallet jacks. Understanding their importance and knowing how to choose the right kit can ensure that your equipment runs smoothly, safely, and efficiently. Regular maintenance and timely replacements of seal kits not only enhance performance but also contribute to a safer working environment. By investing in quality seal kits and following proper maintenance practices, businesses can optimize their pallet jack operations while minimizing costs and risks associated with equipment failure.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories