Ноя . 13, 2024 17:49 Back to list

20 30 7 oil seal

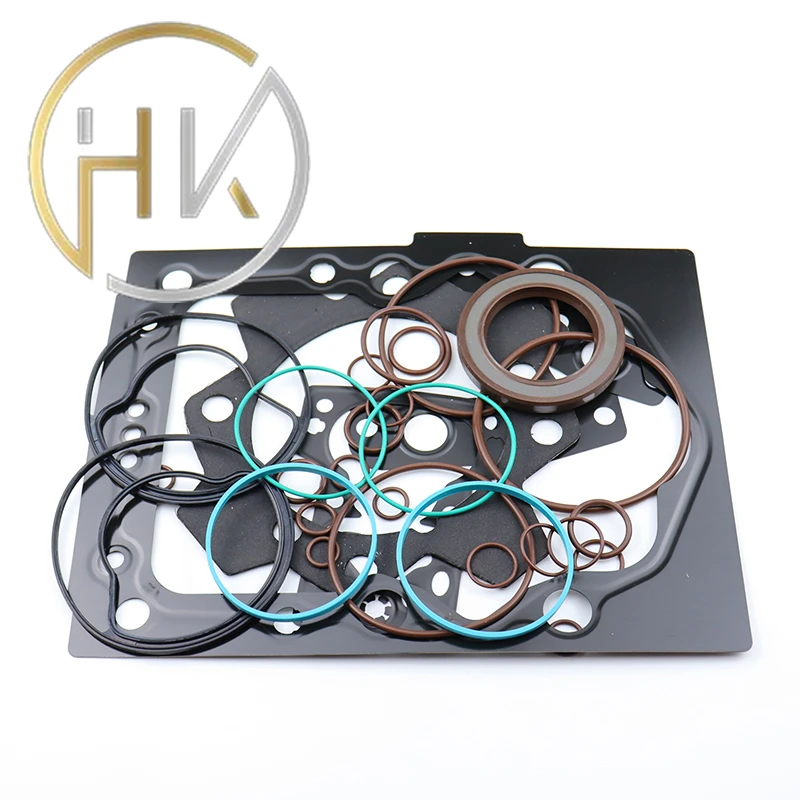

Understanding the Importance of 20/30/7 Oil Seals in Mechanical Applications

Understanding the Importance of 20/30/7 Oil Seals in Mechanical Applications

One of the primary functions of an oil seal is to retain lubricant within a mechanical system while keeping dirt and moisture at bay. The 20/30/7 oil seal excels in this regard, thanks to its precise dimensions and robust construction. Typically made from materials like nitrile rubber, silicone, or fluorocarbon, these seals are designed to withstand fluctuating temperatures and resist degradation from various oils and greases. Their resilience ensures that machinery operates efficiently, minimizing the risk of breakdowns and extending the lifespan of components.

20 30 7 oil seal

The versatility of the 20/30/7 oil seal makes it suitable for a wide range of applications. It is commonly used in automotive industries, particularly in engines and transmission systems, where maintaining the integrity of lubricants is critical. In addition to automotive applications, these seals are also found in agricultural machinery, industrial pumps, and various household appliances. Their ability to function effectively in high-pressure environments further enhances their applicability across different sectors.

Installation and maintenance of oil seals, including the 20/30/7 variant, are crucial for optimal performance. Proper installation techniques are essential to avoid damage and ensure a perfect fit. Engineers and technicians must pay close attention to the surface finish of the shaft and housing, as rough surfaces can lead to premature wear of the seal. Regular maintenance and inspection can help identify wear and tear, allowing for timely replacements to prevent leakage and contamination.

In conclusion, the 20/30/7 oil seal is a vital component in the realm of mechanical engineering. Its robust design, ability to withstand various conditions, and wide range of applications underscore its importance in ensuring the longevity and efficiency of machinery. As industries continue to evolve and technology advances, the demand for high-quality oil seals like the 20/30/7 will remain significant, contributing to improved performance and reliability across multiple sectors. By investing in quality oil seals and adhering to proper installation and maintenance practices, businesses can safeguard their machinery and enhance operational efficiency.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories