nov. . 09, 2024 15:37 Back to list

Hydraulic Pump Seal Kit for Durable and Efficient Performance in Fluid Power Systems

Understanding Hydraulic Pump Seal Kits Essential Components for Performance and Longevity

Hydraulic pumps are vital components in various industrial applications, delivering power and efficiency to a multitude of systems. Whether in construction equipment, manufacturing machinery, or automotive transmissions, maintaining the integrity of these pumps is crucial for optimal performance. One critical element often overlooked is the hydraulic pump seal kit. This article explores the significance, components, and maintenance tips for hydraulic pump seal kits.

What is a Hydraulic Pump Seal Kit?

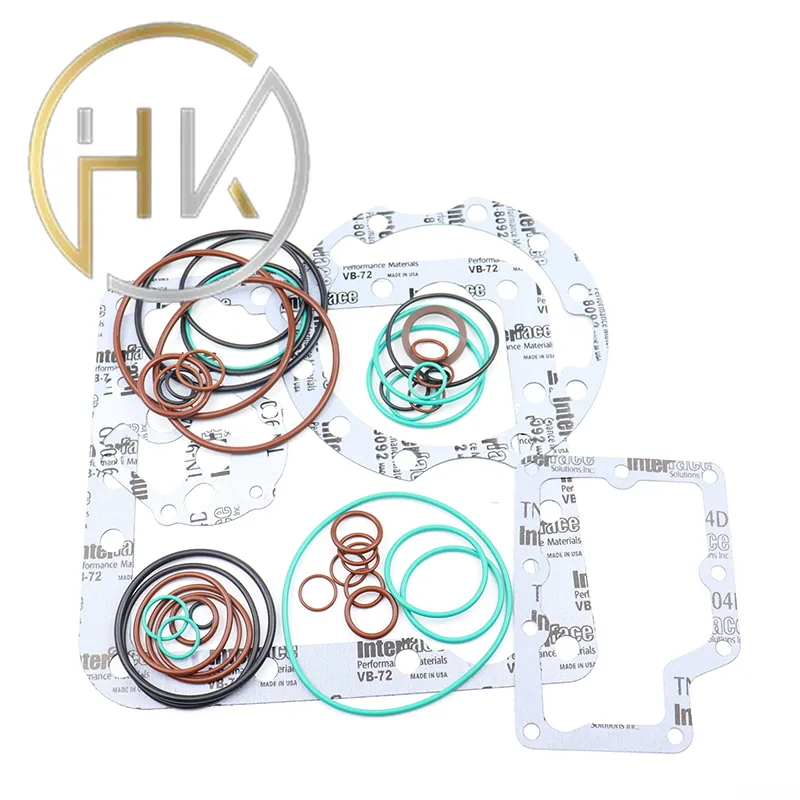

A hydraulic pump seal kit is a collection of seals, O-rings, gaskets, and other essential components designed to prevent fluid leaks in hydraulic systems. These kits play a pivotal role in maintaining the pressure and efficiency of hydraulic pumps by ensuring that hydraulic fluid remains contained within the system. Over time, seals can wear out due to various factors, including high temperatures, pressure fluctuations, and fluid compatibility issues, leading to inefficiencies and potential pump failure.

Components of a Hydraulic Pump Seal Kit

A typical hydraulic pump seal kit includes several critical components

1. O-Rings These circular seals are designed to fit within grooves in the pump assembly to prevent fluid from escaping. O-rings come in various sizes and materials, which can be selected based on the specific fluid and temperature conditions.

2. Gaskets Gaskets are flat seals used to fill the space between two surfaces, such as the pump body and housing. They help to prevent leaks at joint surfaces and are crucial for maintaining the structural integrity of the hydraulic system.

3. Back-up Rings These are used in conjunction with O-rings to provide additional support, especially in high-pressure applications. They help to prevent extrusion of the O-ring, thus enhancing the lifespan of the seal.

hydraulic pump seal kit

5. Bearing Seals Often included in seal kits, bearing seals protect the internal components of the pump from contaminants while ensuring that hydraulic fluid remains in the system.

Importance of Regular Maintenance

Regular maintenance of hydraulic pump seal kits is essential for ensuring the longevity and efficiency of hydraulic systems. Here are some key practices

- Routine Inspection Regularly check for signs of wear, such as cracks, tears, or deformation in seals. Early detection of wear can prevent costly repairs and downtime.

- Fluid Compatibility Use hydraulic fluids that are compatible with the materials used in the seals. Incompatible fluids can degrade seals and lead to premature failure.

- Temperature Monitoring Extreme temperatures can adversely affect seal performance. Monitoring and managing the operating temperature can prolong the life of seals.

- Environment Consideration Protect hydraulic pumps from dust, dirt, and other contaminants. Using filters and ensuring a clean working environment can minimize wear on seals.

Conclusion

The hydraulic pump seal kit is an essential component for anyone who relies on hydraulic systems for their operations. By understanding the components and importance of these kits, operators can ensure that their hydraulic pumps operate efficiently and effectively. Regular maintenance and the timely replacement of seal kits not only enhance performance but also extend the lifespan of the pump, leading to increased productivity and reduced operational costs. For anyone involved in the maintenance of hydraulic systems, investing in a quality seal kit and prioritizing regular inspections is a step towards maintaining the efficiency and reliability of their equipment.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories