Dec . 25, 2024 05:57 Back to list

shaft wipers

The Essential Role of Shaft Wipers in Machinery

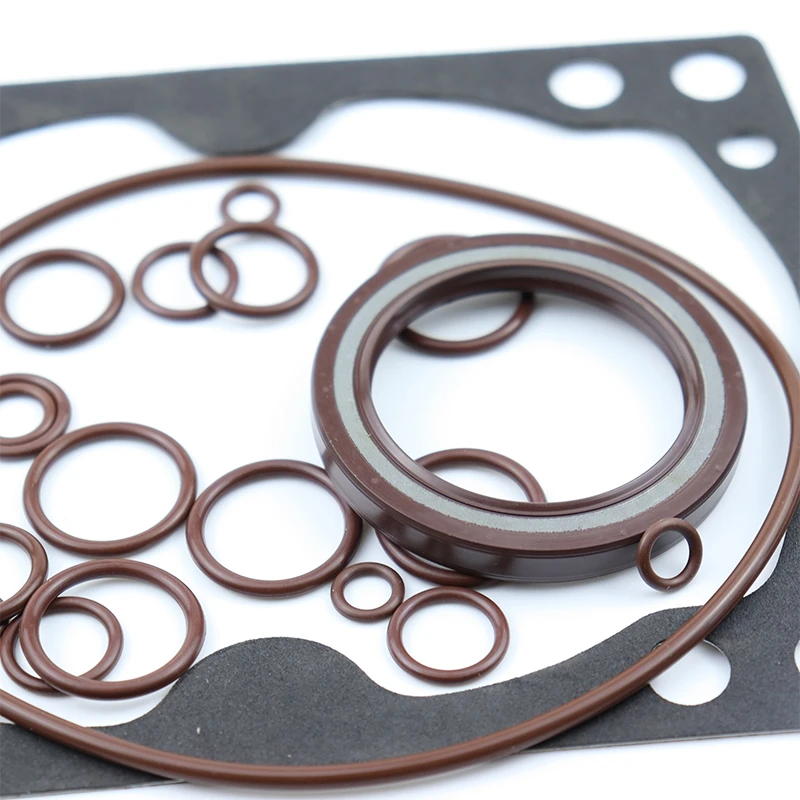

Shaft wipers, often an overlooked component in machinery, play a critical role in maintaining the efficiency and longevity of equipment. Their primary function is to prevent contamination and retain lubrication, ensuring that moving parts can function smoothly without unnecessary wear and tear. In this article, we will explore the significance of shaft wipers, their various types, and best practices for their maintenance.

Understanding Shaft Wipers

Shaft wipers are typically made from various materials such as rubber, polyurethane, or other synthetic compounds, designed to withstand the harsh environments of industrial applications. They're commonly found in hydraulic cylinders, motors, and other rotating equipment where shafts are exposed to dirt, dust, and other debris. The design of the wiper creates a seal that prevents contaminants from entering the machinery while allowing for the necessary movement of the shaft.

Importance in Machinery Performance

The importance of shaft wipers cannot be overstated. By effectively sealing off the entrance points of dirt and debris, they help maintain the integrity of lubricant within the machinery. This is crucial because lubrication reduces friction between moving parts. Reduced friction not only enhances the machinery's efficiency but also minimizes energy consumption and lowers the risk of overheating.

Additionally, contaminated lubricant can lead to increased wear and potential failure of components, resulting in costly downtime for repairs and replacements. Therefore, having properly functioning shaft wipers directly contributes to operational reliability and economic efficiency.

Types of Shaft Wipers

Shaft wipers come in various designs to suit different applications. Some of the common types include

1. Lip Seals These are designed with a flexible lip that presses against the shaft, forming a seal. They are excellent for preventing the ingress of dirt while retaining lubricants.

2. V-Ring Seals These seals provide a V-shaped contact point that allows for movement while sealing out contaminants. They are especially useful in high-motion applications.

shaft wipers

3. Magnetic Wipers These incorporate magnetic elements to attract and hold onto particles that may come into contact with the shaft, ensuring a cleaner operational environment.

Each type has its unique advantages and is chosen based on the specific requirements of the machinery's operating environment.

Maintenance Best Practices

To ensure the longevity and effectiveness of shaft wipers, regular maintenance is essential. Here are some best practices

- Regular Inspection Frequent checks should be carried out to identify any signs of wear or damage to the wipers. Early detection can prevent more extensive damage to the machinery.

- Cleaning Keep the area around the wipers clean to minimize the accumulation of debris that can compromise their effectiveness.

- Replacement Follow manufacturer guidelines for replacement intervals. Worn wipers should be replaced promptly to avoid costly machinery failures.

- Proper Lubrication Make sure that the machinery is adequately lubricated. Insufficient lubrication can lead to excessive wear of the wipers themselves.

Conclusion

Shaft wipers may seem like a minor component, but their role in machinery cannot be ignored. They are essential for keeping equipment running smoothly and efficiently by preventing contamination and maintaining the right lubrication levels. Understanding the importance of these components and implementing best practices for their maintenance ensures that machinery operates reliably, reducing downtime and prolonging equipment life. Investing time and resources in maintaining shaft wipers ultimately leads to significant savings and enhanced performance in industrial settings.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories