Jan . 23, 2025 03:18 Back to list

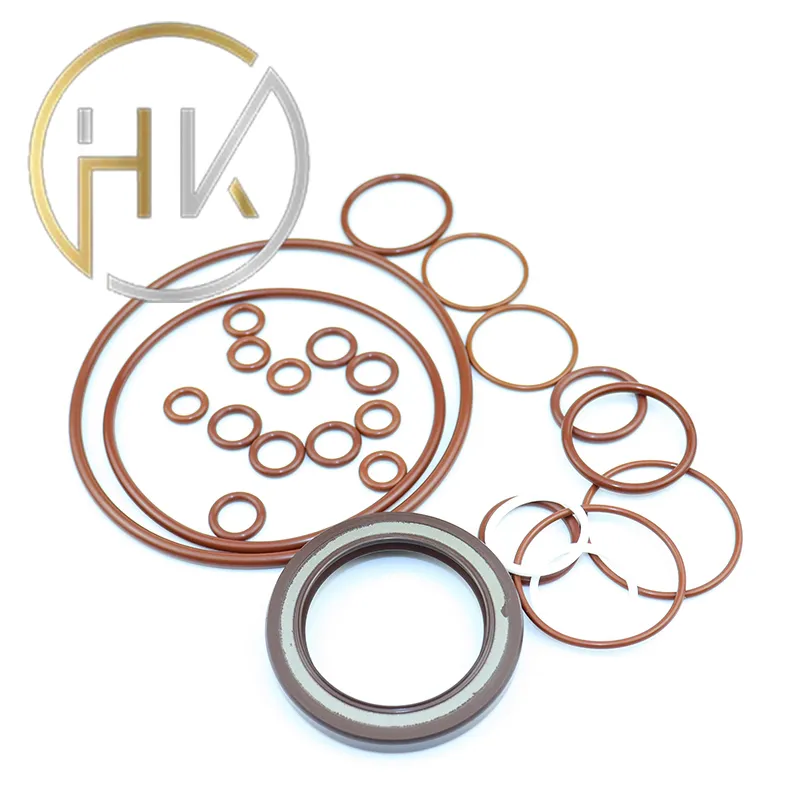

oil pump seal

Expert knowledge in seal selection is crucial. A hydraulic system's efficiency heavily depends on the integrity of its seals. Using mismatched seals can lead to increased maintenance costs, reduced equipment lifespan, and in severe cases, complete system failure. Therefore, it is advisable to seek expert consultation when selecting seals for hydraulic pumps. Regular maintenance and inspection of hydraulic pump seals are paramount to ensure their effectiveness over time. Maintenance routines typically involve checking for leaks, wear and tear, and replacing seals that show signs of degradation. Establishing a maintenance schedule can preempt system failures, ensuring continuous operation and reducing the risk of costly downtime. In situations where seals are exposed to extreme conditions, such as high temperatures or abrasive environments, enhanced seals made from advanced materials like Viton or HNBR (Hydrogenated Nitrile Butadiene Rubber) are recommended. These materials provide better resistance and durability, allowing hydraulic systems to perform effectively under challenging conditions. Moreover, the installation of seals requires precision and care. Incorrect installation can lead to seal damage and subsequent system leakage. Therefore, it is essential to follow manufacturer guidelines and, where necessary, involve qualified technicians for installation. Incorporating feedback from industry veterans and leveraging technological advancements in seal design and materials also plays a critical role in improving system performance. Researchers and engineers are continually developing better sealing technologies, which promise enhanced reliability and efficiency of hydraulic systems. In conclusion, understanding and optimizing the use of hydraulic pump seals is pivotal to the seamless operation of hydraulic systems. With expertise in selecting the right seal types, ensuring proper maintenance, and staying abreast of technological advancements, industries can significantly boost their operational efficiency, maintain safety standards, and ensure the longevity of their equipment. Utilizing high-quality hydraulic seals is not just a matter of performance but also an investment in the overall health of industrial machinery.

-

Cassette Seal 15018014.5/16 Hub Oil Seal | OEM Quality 000051785

NewsAug.31,2025

-

DKBI Hydraulic Wiper Seal 20x32x6/9 | Dustproof & Standard Oil Seal

NewsAug.30,2025

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

NewsAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

Products categories