Jan . 14, 2025 12:13 Back to list

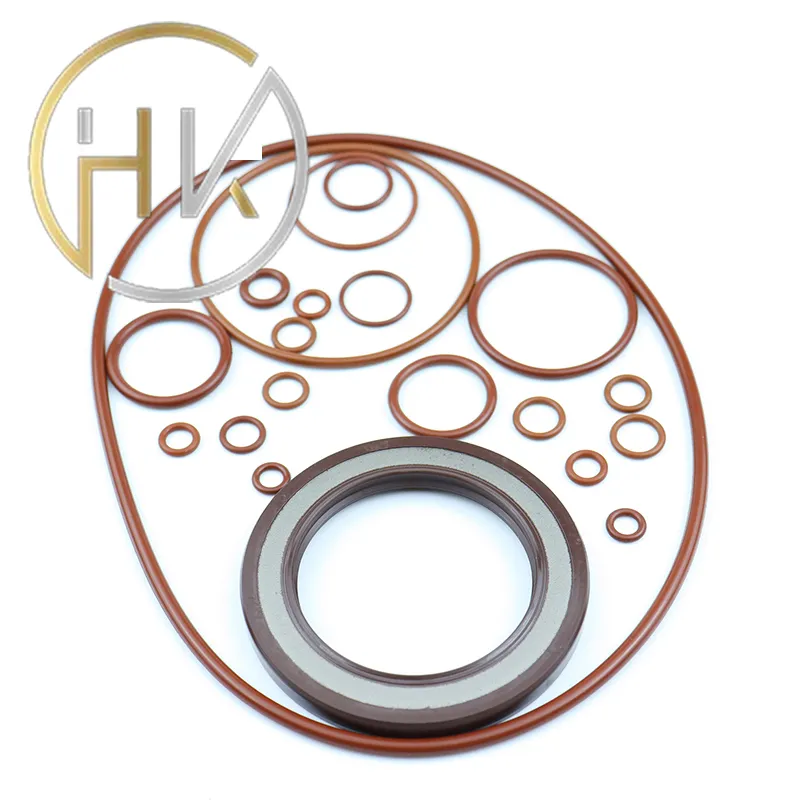

oil seal tcv

Working with TCV oil seals also aligns with an eco-conscious strategy. Their longer lifespan inherently leads to less frequent replacements, cutting down on waste and resource consumption. Furthermore, by ensuring efficient machinery operation, they contribute to reduced energy consumption, thus supporting sustainability initiatives. Another dimension of using TCV oil seals is the peace of mind associated with their installation. The trustworthiness of these components is reflected in numerous industry certifications and standards that they meet or exceed, reinforcing their credibility in demanding environments. I've observed in various industry settings that choosing any lesser alternative often invites risk, which can manifest as unforeseen machinery failures and additional costs. In assessing expertise, TCV continues to invest in research and development, focusing on advancing oil seal technologies to meet future challenges. This forward-thinking approach indicates not only a commitment to current demands but also an authoritative stance on anticipating and shaping the future of mechanical sealing solutions. In conclusion, TCV oil seals are more than just a product; they are an investment in reliability, efficiency, and cost-effectiveness. Embracing TCV means benefiting from a blend of experience, expertise, authoritativeness, and trustworthiness, assuring that every component of your machinery operates seamlessly, regardless of the intensity of the conditions it faces. With TCV, you aren't just choosing a product, but joining a tradition of excellence that aligns perfectly with the sophisticated demands of modern engineering.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories