Nov . 22, 2024 13:23 Back to list

hydraulic motor seal kit

Understanding Hydraulic Motor Seal Kits

Hydraulic motor seal kits play a crucial role in ensuring the efficient and reliable operation of hydraulic systems. These seals are essential components that prevent fluid leaks and protect internal parts from external contaminants. In a hydraulic motor, where various fluids are pressurized to generate motion, the integrity of these seals is paramount for optimal performance and longevity.

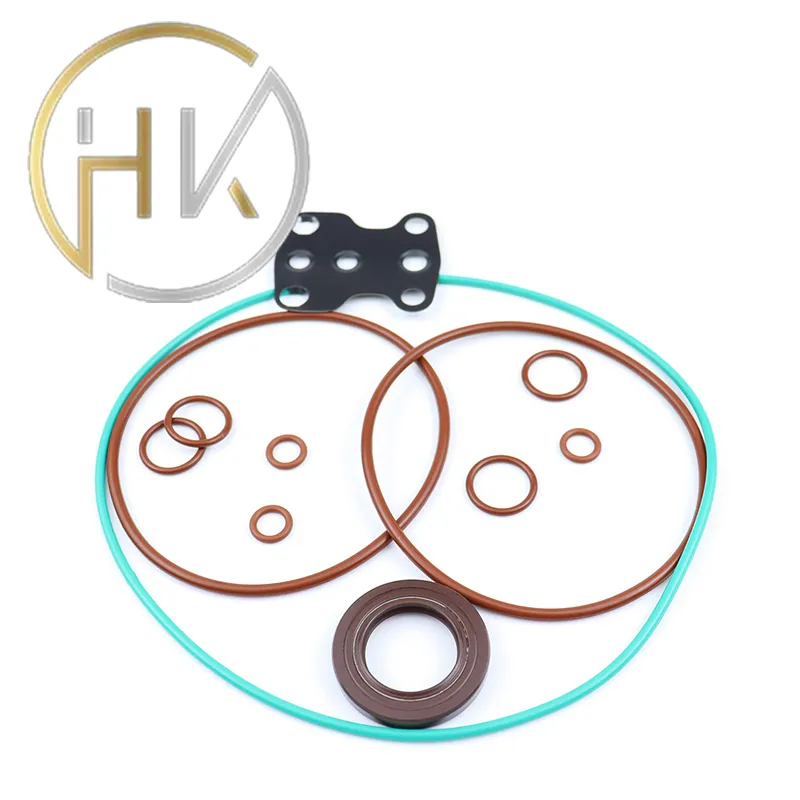

A hydraulic motor essentially converts hydraulic energy into mechanical energy. It relies on precise movement and pressure, which can be compromised if seals fail. Hydraulic motor seal kits typically include O-rings, backup rings, seal rings, and various gaskets, all designed to fit specific models and operating conditions. The materials used in these seals, such as nitrile, polyurethane, or fluoropolymer, are chosen based on their ability to withstand high pressures, temperatures, and the types of fluids involved.

Regular maintenance and timely replacement of hydraulic motor seal kits can prevent catastrophic failures and avoid costly downtime in industrial applications

. An early sign of seal failure is often the presence of fluid leaks, which can not only impact machinery performance but also create hazardous working conditions. Additionally, contaminants entering through worn or damaged seals can lead to increased wear and tear on internal components, resulting in more significant repairs down the line.hydraulic motor seal kit

When selecting a hydraulic motor seal kit, it is essential to consider the specific requirements of your hydraulic system, including operating pressure, temperature range, and compatibility with the hydraulic fluids used. Proper installation is also critical, as improper sealing can lead to premature failure, negating the benefits of the high-quality seals.

Moreover, investing in high-quality seal kits from reputable manufacturers ensures that you receive the durability and performance necessary for your hydraulic applications. Many manufacturers offer comprehensive technical support and guidelines for installation, making it easier for maintenance teams to execute repairs.

In conclusion, hydraulic motor seal kits are vital for the efficiency and reliability of hydraulic systems. By understanding their components, selection criteria, and maintenance practices, operators can extend the lifespan of their equipment, reduce operational costs, and maintain a safe working environment. Ensuring a seamless flow in hydraulic operations is essential, and the right seal kit can make all the difference.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories