Nov . 09, 2024 22:20 Back to list

Hydraulic Cylinder Seal Kit for Efficient Oil Sealing Solutions and Maintenance

Understanding Hydraulic Cylinder Oil Seal Kits

Hydraulic systems are an integral part of various machinery and equipment used in construction, manufacturing, and agriculture. Central to the efficient operation of these systems is the hydraulic cylinder, which converts hydraulic energy into linear motion. One crucial component of a hydraulic cylinder is the oil seal, and to ensure optimal performance, it is essential to utilize a high-quality hydraulic cylinder oil seal kit.

What is a Hydraulic Cylinder Oil Seal Kit?

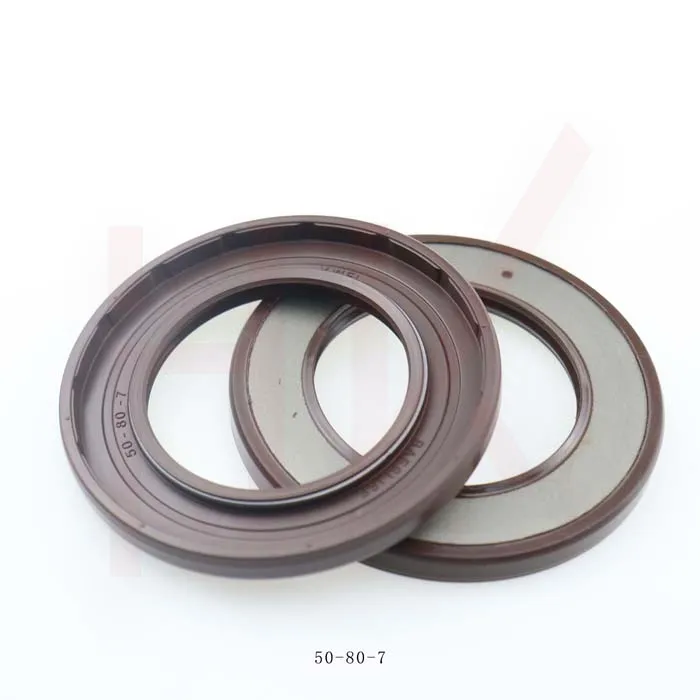

A hydraulic cylinder oil seal kit includes all the necessary components to seal the hydraulic cylinder effectively. These kits typically contain o-rings, piston seals, rod seals, backup rings, and wipers, tailored to fit specific cylinder sizes and designs. The primary function of these seals is to prevent hydraulic fluid leakage while also keeping contaminants out of the system, thus ensuring the hydraulic cylinder operates smoothly and efficiently.

Importance of Oil Seals

Oil seals play a critical role in the longevity and functionality of hydraulic systems. First and foremost, they prevent hydraulic fluid from leaking out of the cylinder, which is essential for maintaining pressure and efficiency. Any loss of hydraulic fluid can lead to a decrease in performance and increased wear and tear on the components.

Additionally, oil seals protect the interior of the hydraulic cylinder from dirt, dust, and other contaminants that can cause damage and reduce the lifespan of the cylinder. Contaminants can lead to abrasive wear on the cylinder walls and piston, resulting in costly repairs and reduced efficiency. Therefore, maintaining the integrity of oil seals is crucial for the overall health of hydraulic systems.

hydraulic cylinder oil seal kit

Selecting the Right Oil Seal Kit

When choosing a hydraulic cylinder oil seal kit, it is important to consider several factors. Compatibility is key; the seals must be designed specifically for the type and size of hydraulic cylinder in use. Using incorrect seals can lead to leaks and ineffective sealing. Additionally, material selection is vital. Common materials include nitrile, polyurethane, and fluorocarbon, each offering varying degrees of chemical resistance and durability. Choosing the right material based on the operating environment and the type of hydraulic fluid used is essential to ensure longevity.

Installation and Maintenance

Proper installation of oil seals is critical for their effectiveness. It is advisable to follow manufacturer guidelines and best practices to avoid damage during installation. Additionally, regular inspection of hydraulic cylinders and oil seals is important. Signs of wear, such as leaks or diminished performance, should prompt immediate attention. Regular maintenance, including the timely replacement of worn seals, can prevent more significant issues and extend the life of hydraulic equipment.

Conclusion

In conclusion, a hydraulic cylinder oil seal kit is a vital component in keeping hydraulic systems running smoothly. By preventing fluid leakage and protecting against contaminants, these seal kits help maintain the efficiency and longevity of hydraulic cylinders. When selecting and installing an oil seal kit, attention to detail is crucial. Proper upkeep of these seals will not only ensure optimal performance but also help in avoiding costly repairs in the long run. Investing in a high-quality hydraulic cylinder oil seal kit is important for any business reliant on hydraulic machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories