Oct . 19, 2024 14:49 Back to list

gland seal kit

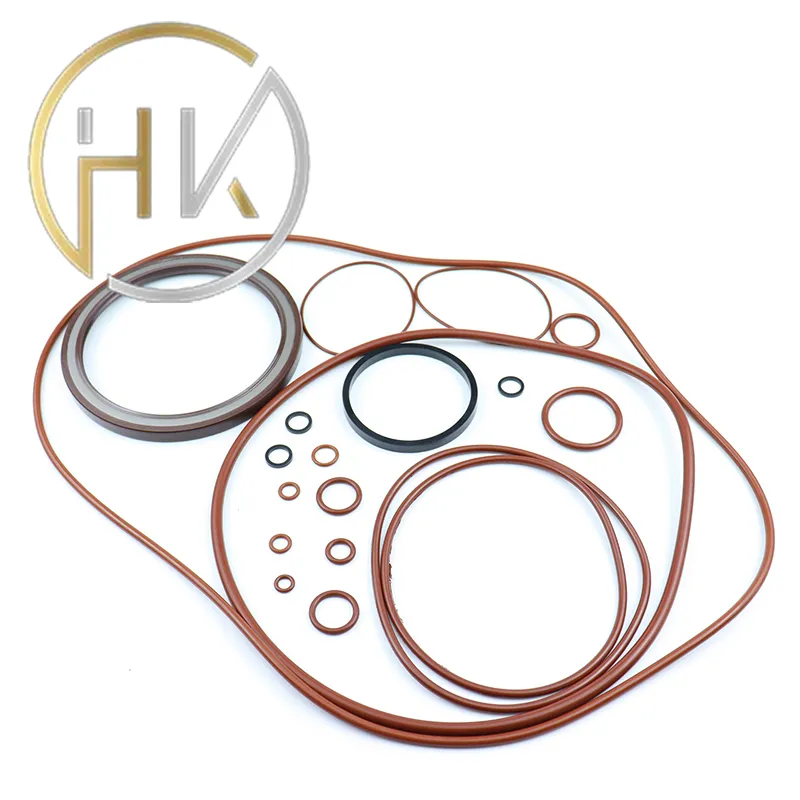

Understanding Gland Seal Kits A Comprehensive Guide

Gland seal kits are essential components in various machinery and industrial applications. These kits play a critical role in providing a reliable sealing solution that prevents the leakage of fluids and maintains operational efficiency. Whether in hydraulic systems, pumps, or any other machinery requiring lubrication or fluid containment, understanding gland seal kits is crucial for both maintenance and optimal performance.

What is a Gland Seal Kit?

A gland seal kit typically consists of various sealing components, including O-rings, seals, gaskets, and sometimes, backup rings. These components work together to form a barrier that prevents fluid leaks from the gland area, which is typically where a shaft or rod passes through a housing or casing. Gland seals are crucial for maintaining pressure and protecting against contamination in hydraulic, pneumatic, and fluid transfer applications.

Components of Gland Seal Kits

1. O-Rings These are circular elastomeric seals designed to sit in a groove and compress when the gland is tightened. The material and size of the O-ring are critical to its sealing ability and the type of fluid it can handle (e.g., oils, water, chemicals).

2. Seals Different types of seals, such as lip seals or radial shaft seals, may also be included in a gland seal kit. These seals offer greater protection against fluid loss and dust or dirt ingress, ensuring that internal components remain lubricated and free from contaminants.

3. Back-Up Rings These are often included in high-pressure applications where O-rings are used. Backup rings prevent the O-rings from extruding or being damaged under high pressure, extending their service life.

4. Gaskets In some kits, gaskets are included to provide an additional sealing solution between flanged connections or two machinery surfaces.

Applications of Gland Seal Kits

Gland seal kits are widely utilized in various industries, including

- Hydraulics In hydraulic cylinders and pumps, preventing hydraulic fluid leakage is paramount for system efficiency. Gland seal kits ensure that the hydraulic fluids remain contained under high pressure.

- Automotive In automobiles, gland seals are found in various components, such as engine oil seals and transmission seals, to prevent leaks that could lead to performance issues.

gland seal kit

- Manufacturing In manufacturing equipment, gland seal kits are essential for maintaining performance and reducing downtime due to leaks.

- Marine Applications In boats and ships, gland seals prevent water ingress into the engine compartments, thus protecting critical machinery from water damage.

Advantages of Using Gland Seal Kits

1. Leak Prevention The primary function of gland seal kits is to effectively prevent the leakage of fluids, maintaining system integrity and efficiency.

2. Cost-Effectiveness Regular maintenance with gland seal kits can significantly reduce costs associated with fluid loss, system downtime, and potential damage to machinery.

3. Customization Gland seal kits can often be customized according to specific requirements, ensuring that they meet the unique needs of a particular application or industry.

4. Extended Equipment Life By providing reliable sealing solutions, gland seal kits contribute to the extended lifespan of machinery, reducing the need for frequent repairs or replacements.

Maintenance and Replacement

Maintaining gland seals involves regularly checking for wear and tear, particularly in high-stress environments. Recommended practices include

- Regular inspections of seals for signs of wear, such as cracks or distortion. - Monitoring fluid levels to detect any potential leaks. - Immediate replacement of any damaged components to prevent further issues.

When replacing gland seal kits, it is essential to select components that match the specifications of the original equipment. Compatibility is critical for ensuring effective sealing and preventing future leaks.

Conclusion

Gland seal kits are a vital part of numerous mechanical systems, providing solutions for preventing leaks and maintaining operational efficiency. Understanding the components, applications, and maintenance of these kits is essential for anyone involved in industries reliant on fluid containment and machinery performance. By investing in quality gland seal kits and adhering to best maintenance practices, industries can enhance their productivity and minimize costs associated with leaks and equipment failure.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories