Jan . 16, 2025 03:04 Back to list

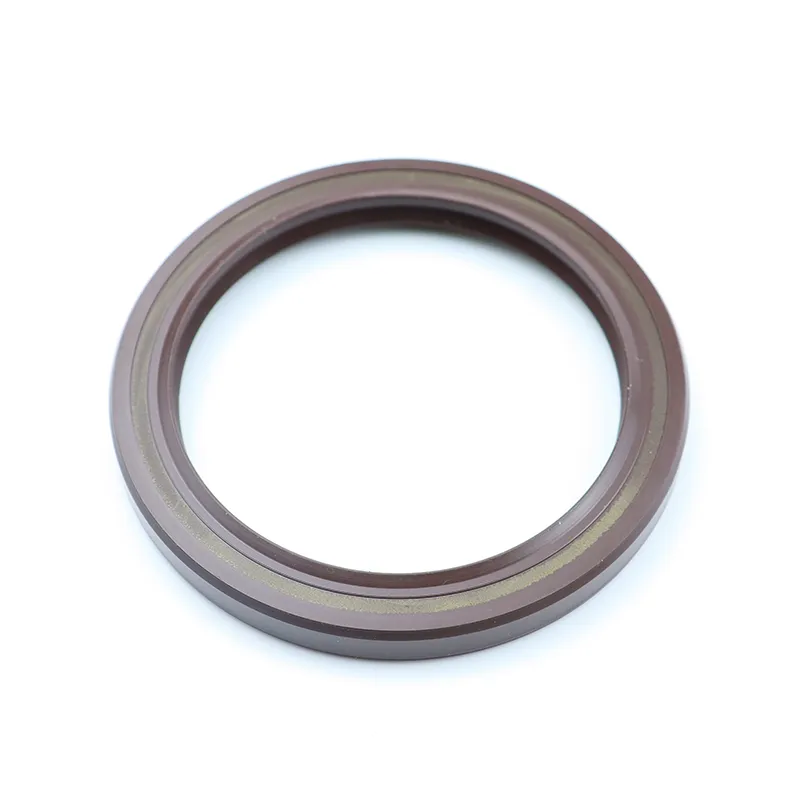

oil seal tcv

Conversely, oil seals are indispensable in systems where maintaining oil or grease is vital for performance. They are commonly found in automotive engines, gearboxes, and any rotary machinery where lubricant leakage could compromise efficiency. Using the wrong seal in such applications can lead to costly repairs and downtime, emphasizing the importance of selecting the appropriate seal type. Proper maintenance of both dust and oil seals is essential for optimal machinery performance. Regular inspection for wear and tear, ensuring that seals are fitted properly, and replacing them promptly when signs of degradation appear can prevent machinery failures. Additionally, understanding the material compatibility of the seals with the machinery environment and the types of fluids used can enhance their effectiveness and lifespan. In conclusion, while dust seals and oil seals may seem similar in function, their specific roles distinguish them significantly. Dust seals protect against external contaminants, crucial for equipment exposed to adverse environments, whereas oil seals not only provide contamination protection but also are vital for preserving lubricants within machinery. Proper selection and maintenance of these seals are paramount for ensuring the reliability, efficiency, and durability of mechanical systems, benefiting longevity and reducing operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories