Dec . 04, 2024 23:27 Back to list

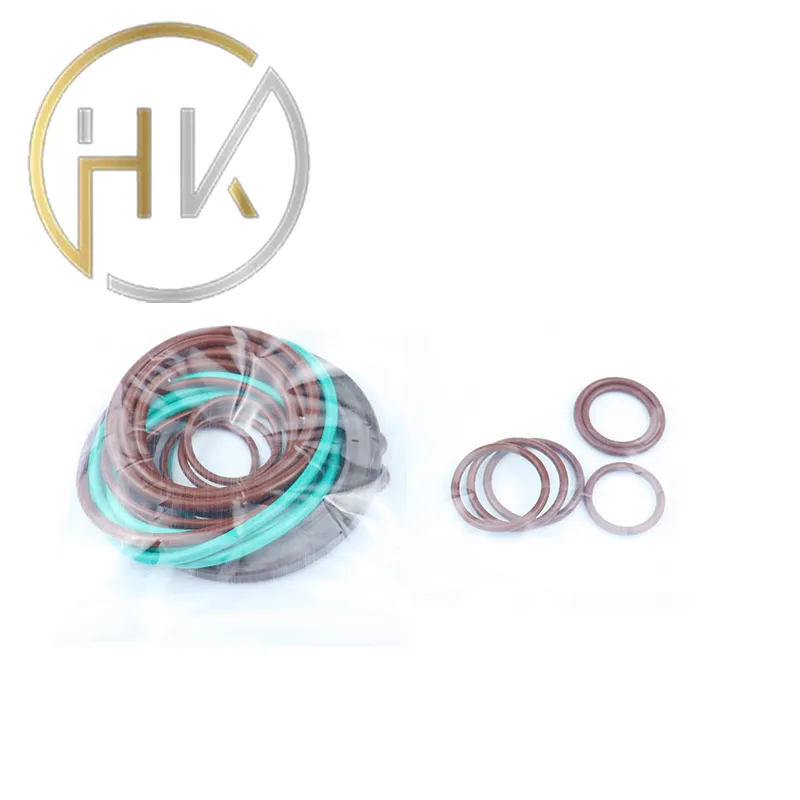

cylinder wiper seal

Understanding Cylinder Wiper Seals An Essential Component in Fluid Power Systems

In the world of fluid power systems, the efficiency and reliability of various components are paramount. One such crucial component is the cylinder wiper seal. Though often overlooked, wiper seals play a vital role in maintaining the integrity and performance of hydraulic and pneumatic cylinders. This article delves into the function, design, materials, and maintenance of cylinder wiper seals, highlighting their significance in modern industrial applications.

The Role of Cylinder Wiper Seals

Cylinder wiper seals, also known simply as wipers, are installed at the outer end of hydraulic and pneumatic cylinders. Their primary function is to prevent contaminants, such as dirt, dust, and moisture, from entering the cylinder while simultaneously removing any debris that may adhere to the rod as it extends and retracts. Without effective wiper seals, contaminants can compromise the cylinder's performance, leading to premature wear, increased friction, and even failure of internal components.

The importance of wiper seals cannot be overstated; they are the first line of defense against external pollutants that could lead to significant system malfunctions. By preserving the cleanliness of the cylinder interior, wiper seals contribute to the longevity and reliability of the entire fluid power system.

Design and Types of Wiper Seals

Wiper seals come in various designs and configurations, each tailored to specific applications and operational conditions. The most common designs include single lip, double lip, and dust wipers.

1. Single Lip Wipers These consist of a single sealing lip that flexes against the cylinder rod. They are simple and effective for applications where the likelihood of contamination is low.

2. Double Lip Wipers Featuring two sealing lips, these wipers offer enhanced protection against dirt and moisture. The first lip wipes the rod, while the second provides additional sealing to prevent contaminants from entering the cylinder.

3. Dust Wipers Often used in conjunction with standard wipers, dust wipers are designed to capture larger particles of debris. They typically have a larger profile and a more robust design to ensure optimal performance.

The choice of design depends on various factors, such as the working environment, the presence of contaminants, and the speed of the cylinder's operation. Manufacturers must consider these factors to ensure the wiper seal provides maximum protection.

Materials Used in Wiper Seals

cylinder wiper seal

The materials utilized in the manufacturing of cylinder wiper seals play a crucial role in determining their performance and durability

. Common materials include- Nitrile Rubber (NBR) Known for its excellent resistance to oil and other petroleum-based fluids, NBR is frequently used in hydraulic applications.

- Polyurethane (PU) Offering high wear resistance and a broad temperature range, polyurethane is ideal for demanding applications where durability is essential.

- Fluoroelastomer (FKM) Particularly effective in high-temperature and chemical-resistant applications, FKM seals are designed to withstand harsh environments.

The selection of material influences not only the seal's performance but also its compatibility with different fluids, temperatures, and operating conditions.

Maintenance and Care of Wiper Seals

To ensure that cylinder wiper seals function effectively, regular maintenance is essential. This includes

- Inspections Routine checks for wear and tear or damage can help identify issues before they become serious problems.

- Cleaning Keeping the rod and surrounding areas clean can significantly extend the life of the wiper seals. Simple cleaning procedures should be part of any maintenance routine.

- Replacement If a wiper seal shows signs of significant wear or damage, it is crucial to replace it promptly. Failing to do so can lead to larger issues within the hydraulic or pneumatic system.

Conclusion

Cylinder wiper seals are integral components of fluid power systems that protect against contamination and ensure the reliable operation of hydraulic and pneumatic cylinders. By understanding their function, design, materials, and maintenance needs, engineers and maintenance personnel can enhance the performance and lifespan of these vital systems. Investing in quality wiper seals and adhering to proper maintenance practices can result in significant long-term benefits, making them an essential consideration in any fluid power application.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories