Dec . 04, 2024 09:34 Back to list

bearing dust seal

Understanding the Importance of Bearing Dust Seals

Bearings play a crucial role in the smooth functioning of machinery by allowing rotational or linear movement while minimizing friction. While bearings are engineered to handle heavy loads and resist wear, their performance can be significantly compromised by contaminants like dust, dirt, and moisture. This is where dust seals come into play. In this article, we will delve into the importance of bearing dust seals, how they function, and their impact on bearing longevity.

What Are Bearing Dust Seals?

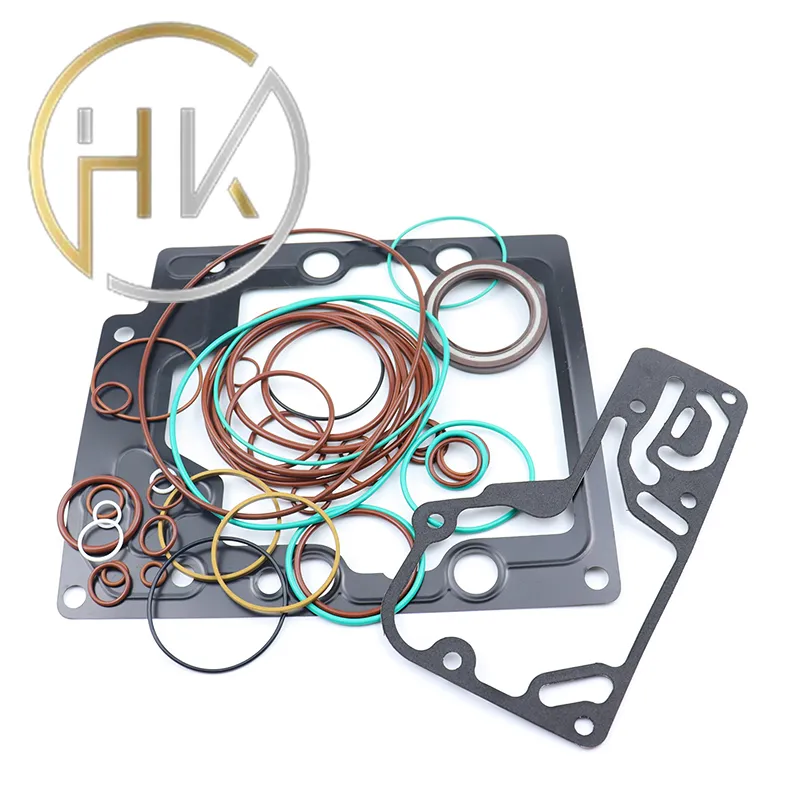

Bearing dust seals are protective components that prevent contaminants from entering the bearing's inner workings. Typically made from materials such as rubber or polymer, these seals form a tight barrier around the bearing. They are designed to withstand wear and the rigors of different operating conditions, contributing significantly to the overall reliability of the machinery in which they are used.

The Function of Dust Seals

The primary function of dust seals is to keep out dust, dirt, and moisture that can adversely affect bearing performance. By creating a barrier, these seals help maintain a clean environment within the bearing, allowing it to operate at optimum efficiency. Additionally, dust seals can help retain lubrication, which further enhances the bearing's performance. Proper lubrication is essential for minimizing friction and heat generation, both of which can lead to premature bearing failure.

Types of Bearing Dust Seals

There are various types of bearing dust seals, and the choice of seal will depend on the specific application

.1. Lip Seals These are the most common type of dust seals. They feature a flexible lip that creates a tight seal against the bearing. Lip seals are known for their effectiveness in excluding contaminants while allowing some lubrication to lubricate the bearing.

2. Labyrinth Seals These are designed with a series of grooves that create a tortuous path for any contaminants attempting to enter the bearing. Labyrinth seals are often used in high-speed applications due to their ability to withstand extreme conditions.

bearing dust seal

3. Contact Seals Unlike lip seals, contact seals maintain constant contact with the bearing surface. While they provide excellent sealing capabilities, they can introduce some friction, which can affect performance in certain situations.

4. Non-contact Seals These seals do not touch the bearing surface, which reduces friction; however, they may be less effective at preventing contaminants entry compared to contact seals.

Benefits of Bearing Dust Seals

1. Extended Bearing Life By preventing dirt and moisture from entering the bearing, dust seals can significantly prolong the operational lifespan of the bearing. This translates to reduced maintenance costs and increased productivity.

2. Improved Performance Clean bearings operate more efficiently and with less friction, leading to smoother operation and reduced energy consumption.

3. Reduced Downtime By enhancing the durability and reliability of bearings, dust seals can mitigate unexpected failures that would otherwise lead to costly downtime.

4. Versatility Bearing dust seals are available in various materials and configurations, making them suitable for a wide range of applications, from automotive to industrial machinery.

Conclusion

Bearing dust seals are critical components that protect bearings from harmful contaminants, ensuring smooth and efficient operation. Their ability to maintain a clean environment within the bearing not only extends the service life of the bearing but also improves overall machinery performance. As industries continue to demand higher efficiency and reliability, investing in quality bearing dust seals will be essential for maintaining competitive advantage and operational excellence. Understanding the importance of these seals can provide valuable insights for engineers and maintenance professionals aiming to optimize machinery performance and reliability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories