sty . 09, 2025 11:24 Back to list

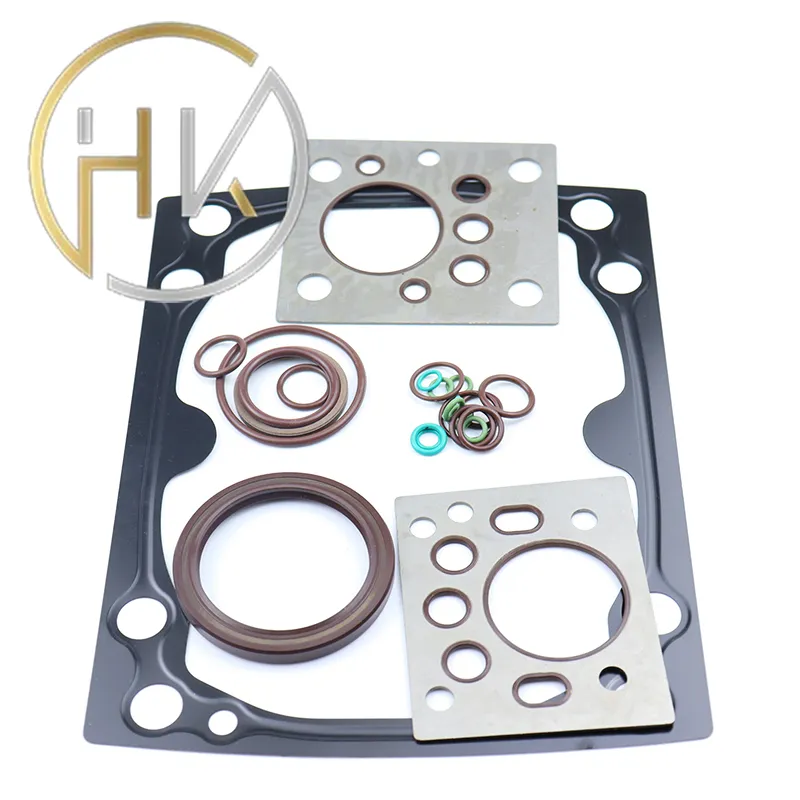

oil seal factory

Authoritativeness in this realm is often established through certifications, partnerships, and affiliations. A credible oil seal factory might possess certifications from international standards organizations such as ISO, which assures clients of their adherence to quality management principles. Furthermore, partnerships with leading material suppliers or affiliations with industry bodies signal a respected position within the marketplace. These factors serve as endorsements of the factory's commitment to quality and innovation, reinforcing its authority as a key player in the industry. Trustworthiness is integral to fostering long-term relationships with customers. An oil seal factory that consistently delivers on its promises, offers transparent communication, and upholds rigorous standards manifests trust with its clientele. Testimonials and case studies can provide insight into the factory’s reputation, shedding light on their track record in delivering durable and reliable products. Additionally, a trustworthy factory often extends its commitment to service beyond the sale, offering comprehensive after-sales support and consultations to ensure client satisfaction and product longevity. In conclusion, when evaluating an oil seal factory, assessing it through the lenses of experience, expertise, authoritativeness, and trustworthiness can guide buyers in making informed decisions. The right factory will not only offer superior products but also provide valuable partnerships that enhance operational efficiencies. As industries continue to evolve, those factories that excel in these four pillars will undoubtedly lead the charge in delivering seals that stand the test of time, ensuring mechanical precision and reliability for their clients' most crucial applications.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories