ਨਵੰ. . 08, 2024 03:56 Back to list

Understanding the Importance of Wiper Seals in Automotive Applications and Maintenance Tips

Understanding Wiper Seals Functionality and Importance

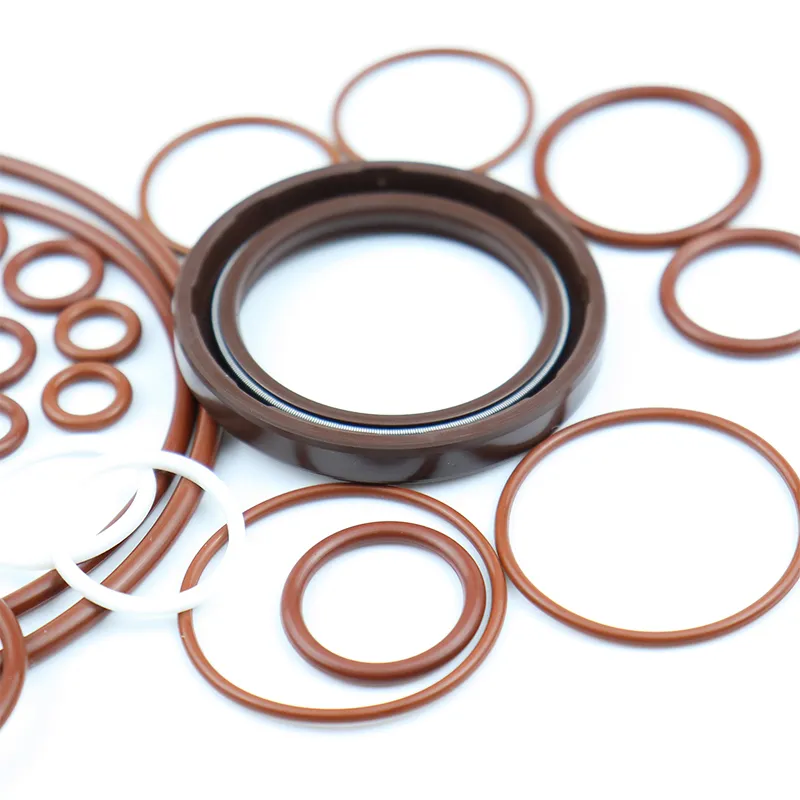

Wiper seals, often overlooked yet crucial components in various mechanical systems, play a vital role in ensuring the smooth operation and longevity of equipment. These specially designed seals are commonly found in hydraulic cylinders, automotive applications, and machinery where lubrication is necessary. Their primary function is to prevent contaminants from entering the system while keeping the lubricants contained, thus maintaining optimal performance.

The Role of Wiper Seals

Wiper seals are typically positioned at the outermost part of a hydraulic cylinder. Their main responsibility is to wipe away dirt, dust, and other debris from the rod as it extends and retracts. This action prevents harmful particles from entering the hydraulic system, which can cause wear and tear on the seals and other internal components. The presence of contaminants can lead to decreased efficiency, hydraulic fluid leaks, and even catastrophic failures if left unaddressed.

Types of Wiper Seals

Wiper seals come in a variety of materials and designs, tailored for different applications. Common materials include polyurethane, rubber, and fluoropolymers, each with its own unique properties. For instance, polyurethane is known for its durability and resistance to wear and tear, making it suitable for harsh environments. In contrast, rubber seals are often employed in less demanding applications due to their cost-effectiveness and good sealing capabilities.

wiper seals

Moreover, the design of wiper seals can vary significantly. Some may feature a simple lip design, while others have multiple lips or additional wiper features for enhanced cleaning capability. The choice of design often depends on the application requirements, including the speed of operation, exposure to harsh chemicals, and temperature fluctuations.

The Importance of Proper Installation

The effectiveness of wiper seals does not solely rely on their construction and materials; proper installation is equally critical. A poorly installed wiper seal can lead to gaps, allowing contaminants to infiltrate the system. It can also cause excessive friction, resulting in accelerated wear or failure. Therefore, it is essential to follow manufacturer guidelines during installation to ensure the seals function as intended.

Regular maintenance and periodic inspection of wiper seals are also vital for ensuring their longevity. Signs of wear, such as fraying or cracking, should be addressed promptly. Neglecting these issues can lead to significant complications, including fluid leaks and system inefficiencies.

Conclusion

In conclusion, wiper seals are integral to the operation of many mechanical systems, safeguarding against contaminants and ensuring optimal performance. Their design, material, and proper installation are key factors that influence their effectiveness. Industries that utilize hydraulic systems, automotive sectors, and various machinery must pay close attention to the condition and maintenance of these seals. Investing time and resources into understanding and maintaining wiper seals can result in enhanced efficiency, reduced downtime, and ultimately, increased productivity. As technology evolves and machinery becomes more complex, the importance of reliable sealing solutions like wiper seals will undoubtedly continue to grow, making them a critical focus for engineers and maintenance professionals alike.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories