ਨਵੰ. . 14, 2024 04:44 Back to list

wiper seal

The Importance of Wiper Seals in Automotive Applications

Wiper seals are often an overlooked component in automotive design, yet they play a crucial role in ensuring the performance and longevity of various mechanical systems. These seals are designed to prevent contaminants from entering critical areas of machinery while also keeping essential fluids where they belong. In this article, we will explore the function, types, materials, and significance of wiper seals in vehicles.

What Are Wiper Seals?

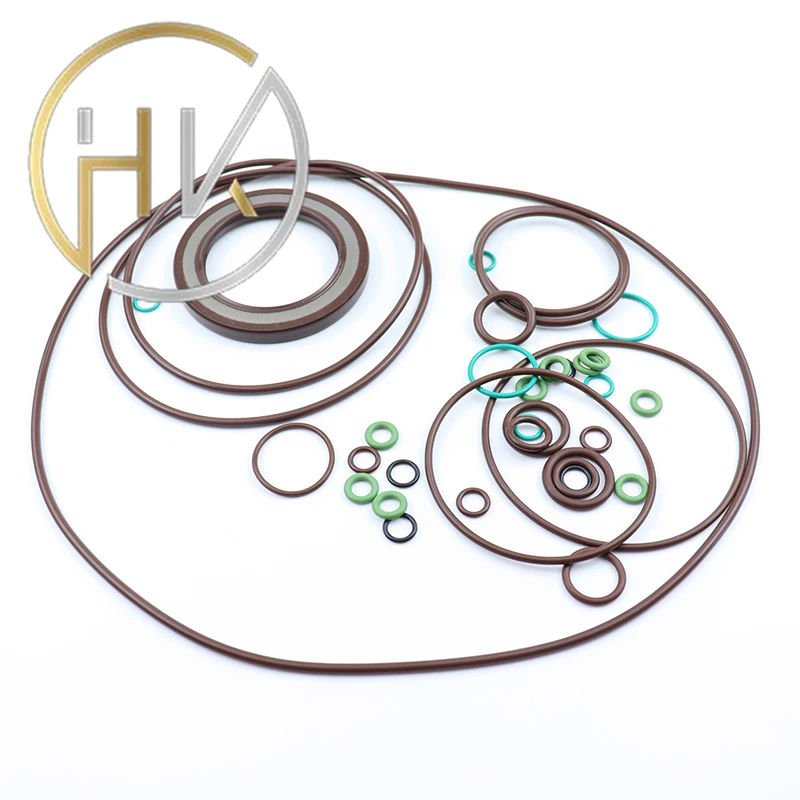

Wiper seals are types of seals that are typically installed in conjunction with other sealing devices, such as O-rings and lip seals. Their primary function is to wipe away dirt, dust, and debris from sliding surfaces in hydraulic and pneumatic cylinders, thereby preventing these contaminants from causing damage to more delicate internal components. By doing so, wiper seals help maintain the integrity of the system, thereby reducing wear and extending the life of the machinery.

Types of Wiper Seals

There are a variety of wiper seals available, each designed for specific applications and environments. Some common types include

1. U-Cup Seals These seals have a U-shaped cross-section, allowing them to provide effective wiping action while accommodating movement in dynamic applications.

2. V-Ring Seals Shaped like a 'V', these seals are particularly effective in sealing rotating shafts and preventing ingress of particulates.

3. Flat Wiper Seals Often used in applications with minimal movement, these seals feature a flat design and offer a simple yet effective solution for wiping surfaces.

4. X-Ring Seals These seals are designed to provide improved sealing capabilities while also minimizing friction.

Each type of wiper seal has its own set of characteristics tailored for specific conditions, such as high pressure, temperature extremes, or aggressive chemical environments.

Materials Used in Wiper Seals

wiper seal

The materials selected for wiper seals are critical to their performance and durability. Common materials include

- Polyurethane Known for its excellent abrasion resistance and flexibility, polyurethane is ideal for a wide range of applications.

- Nitrile Rubber (Buna-N) A versatile and cost-effective option, nitrile rubber is resistant to petroleum-based oils but may not perform well in extreme temperatures.

- Fluoroelastomers (e.g., Viton) These materials offer high-temperature resistance and excellent chemical compatibility, making them suitable for harsh environments.

- Silicone While less abrasive than other materials, silicone can handle extreme temperatures and is often used in applications where flexibility is required.

Selecting the appropriate material based on the specific operational conditions can significantly enhance the performance of wiper seals.

Significance of Wiper Seals in Vehicles

In the automotive industry, wiper seals are essential for the efficiency of hydraulic systems such as those found in power steering and brake systems. Their ability to keep out contaminants ensures that these systems operate smoothly and reliably, contributing to overall vehicle safety. Furthermore, wiper seals help maintain fluid levels, preventing leaks that can lead to catastrophic failures.

Moreover, wiper seals play a vital role in enhancing the performance of adjustable components, such as suspension systems. By keeping debris out, they allow for consistent operation of shock absorbers and struts, which in turn ensures a smooth ride for passengers.

In addition to improving functionality, proper wiper seal installation and maintenance can lead to cost savings over time. Fewer leaks and failures mean lower repair costs and extended intervals between service sessions.

Conclusion

In summary, wiper seals are a fundamental component of automotive machinery that should not be underestimated. Their primary role in preventing contaminants from entering critical components enhances system reliability, longevity, and overall vehicle safety. By understanding the various types and materials of wiper seals and their significance in automotive applications, manufacturers and consumers alike can make more informed decisions, contributing to improved performance and durability in vehicles. As automotive technology continues to advance, the role of wiper seals will remain essential in ensuring that vehicles operate efficiently and safely, long into the future.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories